The

clutch

Section

H

Description

The clutch assembly comprises a spring pressure

plate assembly and a single dry 158·75mm

(6·25in)

diameter clutch plate.

As

an alternative

a diaphragm

clutch assembly,

which

is

interchangeable

with

the spring pressure plate

assembly

will

sometimes be fitted.

The clutch pedal lever operates a cable linked

to

the clutch operating arm and a trunnion

which

acts

as

an

abutment

for

the cable adjuster.

Routine maintenance

Check and adjust clutch every 3,000 miles

(5,000km).

The clutch assembly

The clutch is located on the flywheel by

two

dowels

and retained by six set screws and

lockwashers. Before dismantling, mark

all the

major components so that they can be

reassembled in the same relative positions, thus

preserving balance and adjustment.

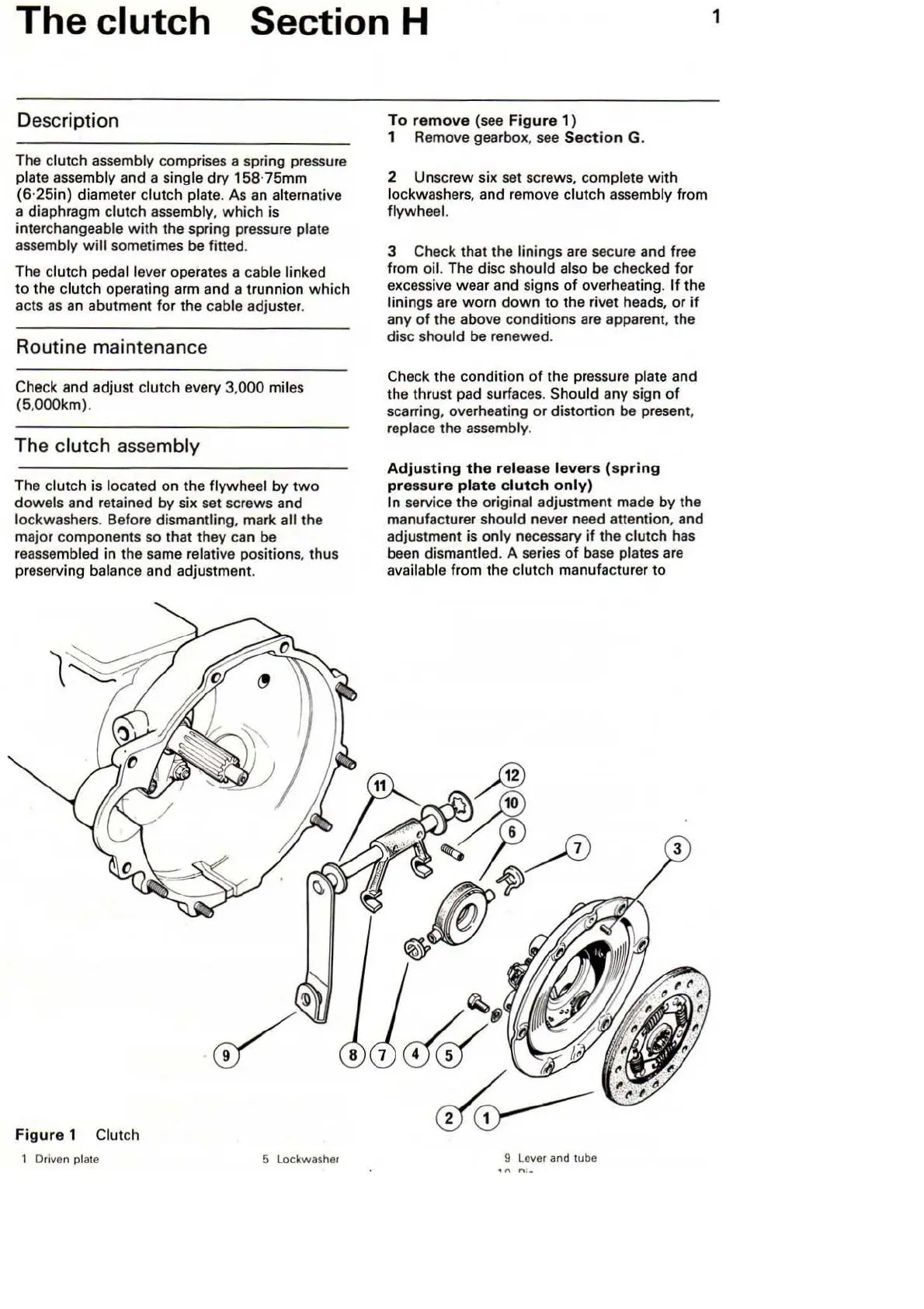

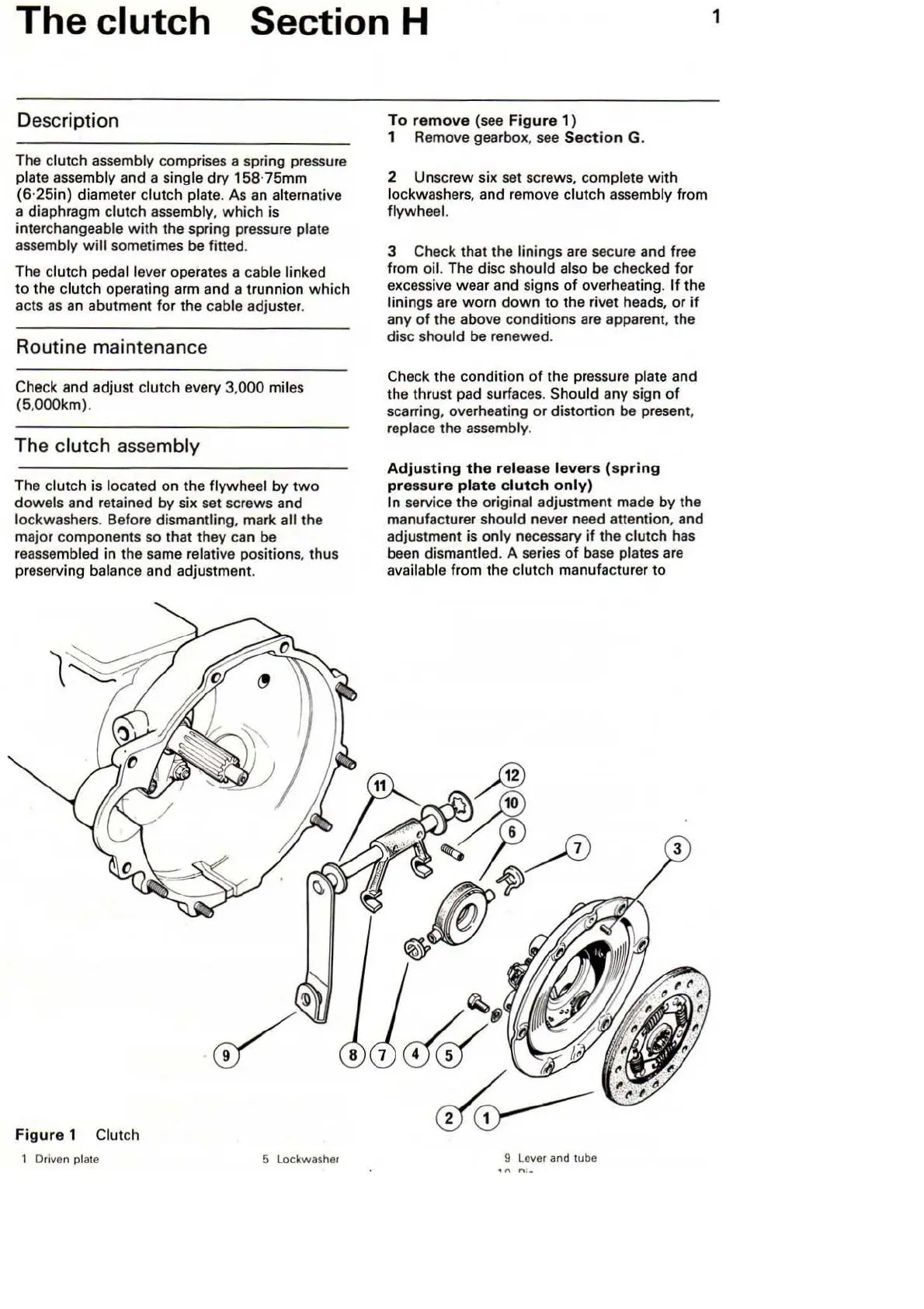

Figure

1 Clutch

1 Driven plate 5 Lockwasher

To

remove

(see

Figure

1)

1 Remove gearbox, see

Section

G.

2 Unscrew six set screws, complete

with

lockwasher

s,

and remove clutch assembly from

flywheel.

3 Check that the linings are secure and free

from oil. The disc should also be checked for

excessive wear and signs

of

overheating.

If

the

linings

are

worn

down

to

the rivet heads.

or

if

any

of

the above conditions are apparent, the

disc should be renewed.

Check the condition

of

the pressure plate and

the thrust

pad

surfaces

. Should

any

sign

of

scarring, overheating

or

distortion be present.

replace the assembly.

Adju

sti

ng

the

release

lever

s

(spring

pres

su

re

plate

clutch

only)

In service the original adjustment made by the

manufacturer should never need attention, and

adjustment is only necessary

if

the clutch has

been dismantled. A series

of

base plates are

available from the clutch manufacturer

to

9 Lever and tube

, "

"'

'-

1

Loading...

Loading...