Section 7: Replacement Procedures

Page 7-4

CG4 Series Service Manual

7.1 PRINT HEAD REPLACEMENT (cont’d)

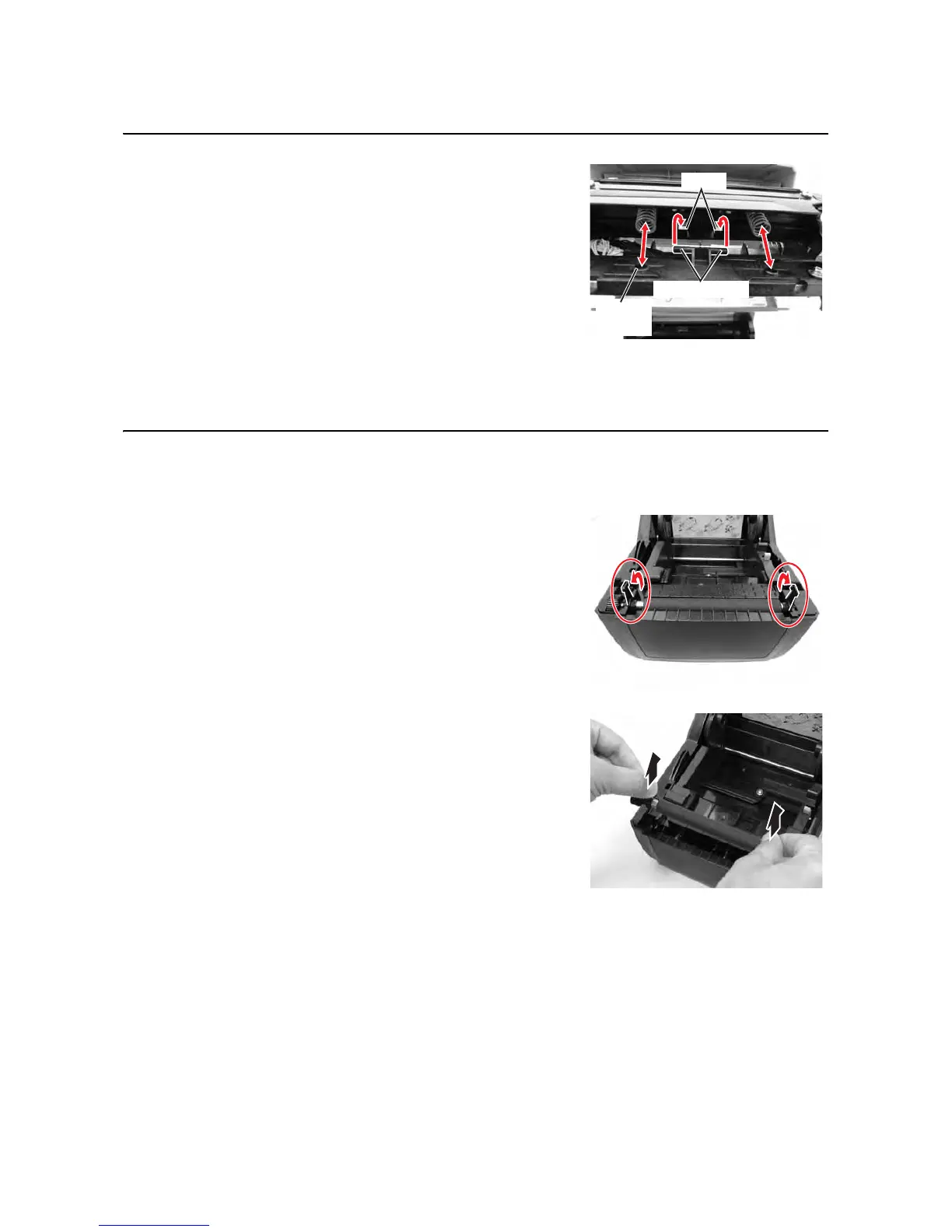

8.

Align the two circular recess of the print head bracket to

the two

springs attached to the top cover frame. At the

same time, fix the

fulcrum shaft of the print head bracket

to the

hooks. While pressing the print head, slide the print

head release lever

to lock the print head assembly in

place.

9. Restore power, reload media and ribbon, reset the head

counter (refer to

Section 4.12 Factory Clear Mode) and

perform a test print to ensure that the

print head is

connected properly.

7.2 PLATEN ROLLER REPLACEMENT

The printer’s platen roller is considered to be a high-wear component due to constant treading of the print

media and ribbon stock against its contact surface. This constant contact will eventually wear grooves into the

rubber material and negatively effect print output.

1. Make sure the printer is powered off and remove the power

cable.

2. Lift the Top Cover.

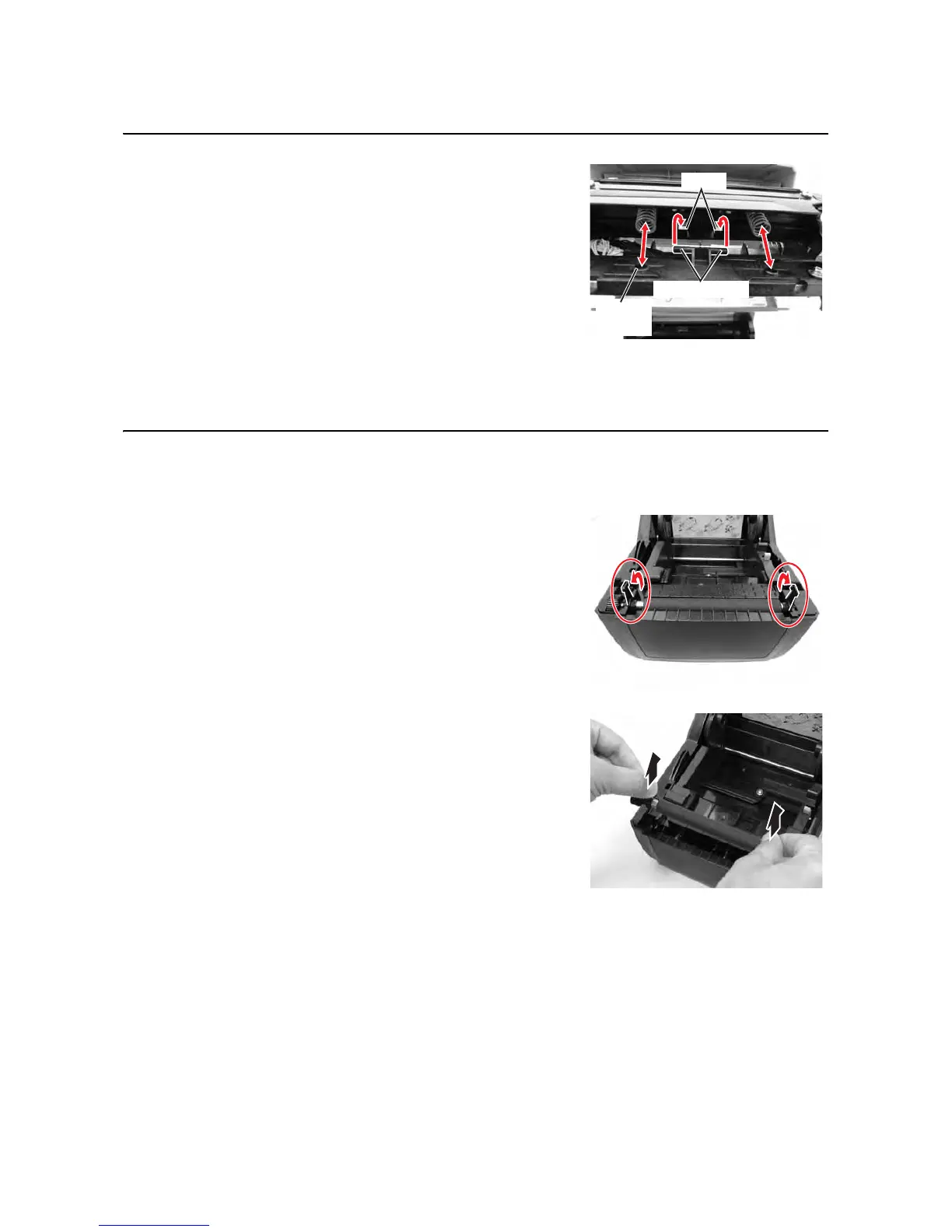

3. Locate the two platen bearings on each side of the platen

roller

, and turn the handles in the direction as shown.

4. Lift up the defective platen roller assembly with the

handles and replace it with a new one.

5. Follow the above steps, in reverse sequence, to

reassemble the parts. Make sure that the

platen bearing

snaps back in position.

Perform a label feed to ensure the

platen roller is

assembled correctly.

Loading...

Loading...