Chapter 6 Operating Instructions

CLV65x Bar Code Scanner

58 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011980/0000/2009-04-21

Electrical installation

6.4 Performing electrical installation

Important To ensure secure fastening of the connected connectors and adherence to the enclosure

rating, the knurled nuts/coupling rings of the M12 connectors have to be tightened or the

cable connectors have to be secured.

1. Connect or release current linkages only under de-energised conditions.

2. All wire cross sections and their shields on customer side have to be selected and im-

plemented according to valid engineering standards.

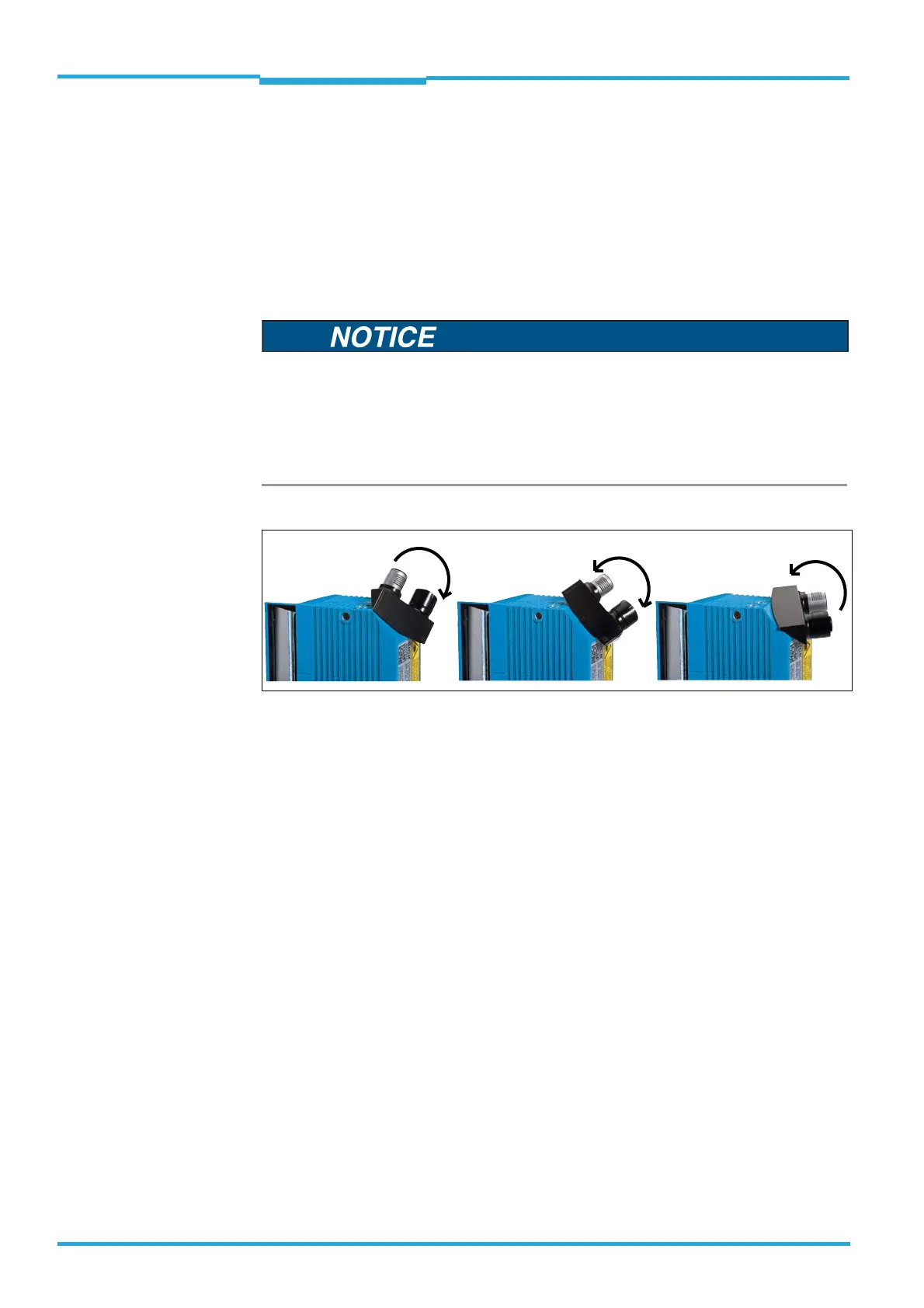

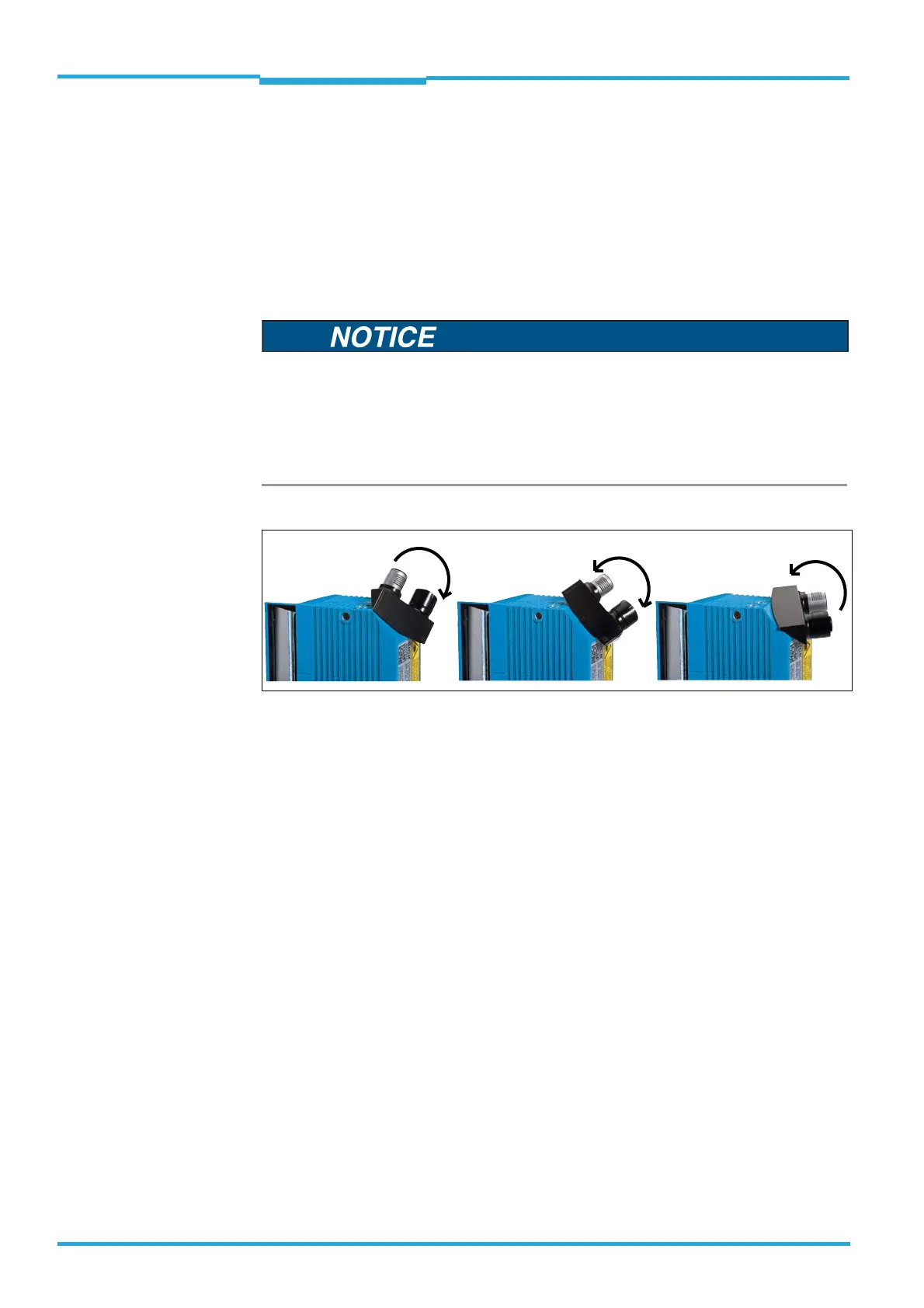

Fig. 6-3: Direction of rotation of the connector unit

6.4.1 Connecting the power supply for the bar code scanner

The bar code scanner requires a supply voltage of 18 ... 30 V (functional extra-low voltage

in accordance with IEC 60364-4-41 (VDE 0100 Part 410)). The functional extra-low voltage

can be created using a safety transformer in accordance with IEC 742 (VDE 0551). The ma-

ximum current consumption is 8.5 ... 9.5 W.

The bar code scanner is supplied with 18 ... 30 V DC via connection module CDB620 or

CDM420. If the power supply module CMP400/CMP490 is used, the input voltage is

100 ... 250 V AC/ 50 ... 60 Hz at the module.

Important The output circuit of the power supply must be electrically separated from the input circuit.

This is usually created by means of a safety transformer in accordance with IEC 742

(VDE 0551).

Damage to the connector unit at the bar code scanner due to overwinding.

The connector unit at the bar code scanner has two end positions.

Never turn the connector unit more than 180° in one direction (comming from one of

the end positions).

Always rotate the connector unit in the direction of the laser diode name.

Loading...

Loading...