The safety laser scanner’s configuration memory is integrated in the system plug. The

s

ystem plug and all connecting cables can remain at the installation site when the

safety laser scanner is replaced. The system plug is detached from the defective safety

laser scanner and connected to the new safety laser scanner. The new safety laser

scanner reads the configuration from the configuration memory when switched on.

3.3.3 Field types

During operation, the safety laser scanner uses its laser beams continuously to check

whe

ther people or objects are present in one or more areas. The areas to be checked

are called fields. A distinction is made between the following field types, depending on

how the safety laser scanner is used:

•

Protective field

•

Contour as Reference field

•

Contour detection field

•

Warning field

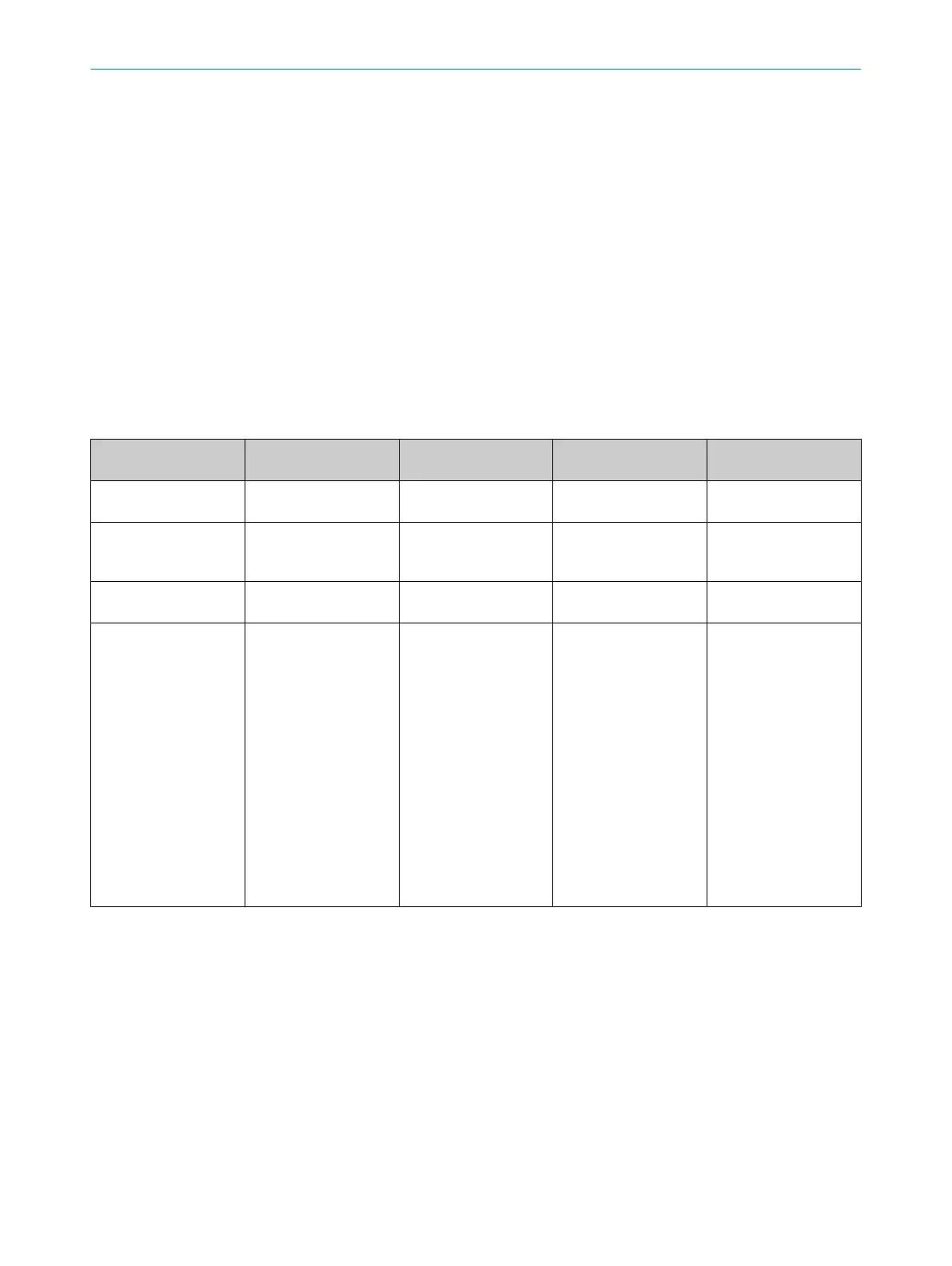

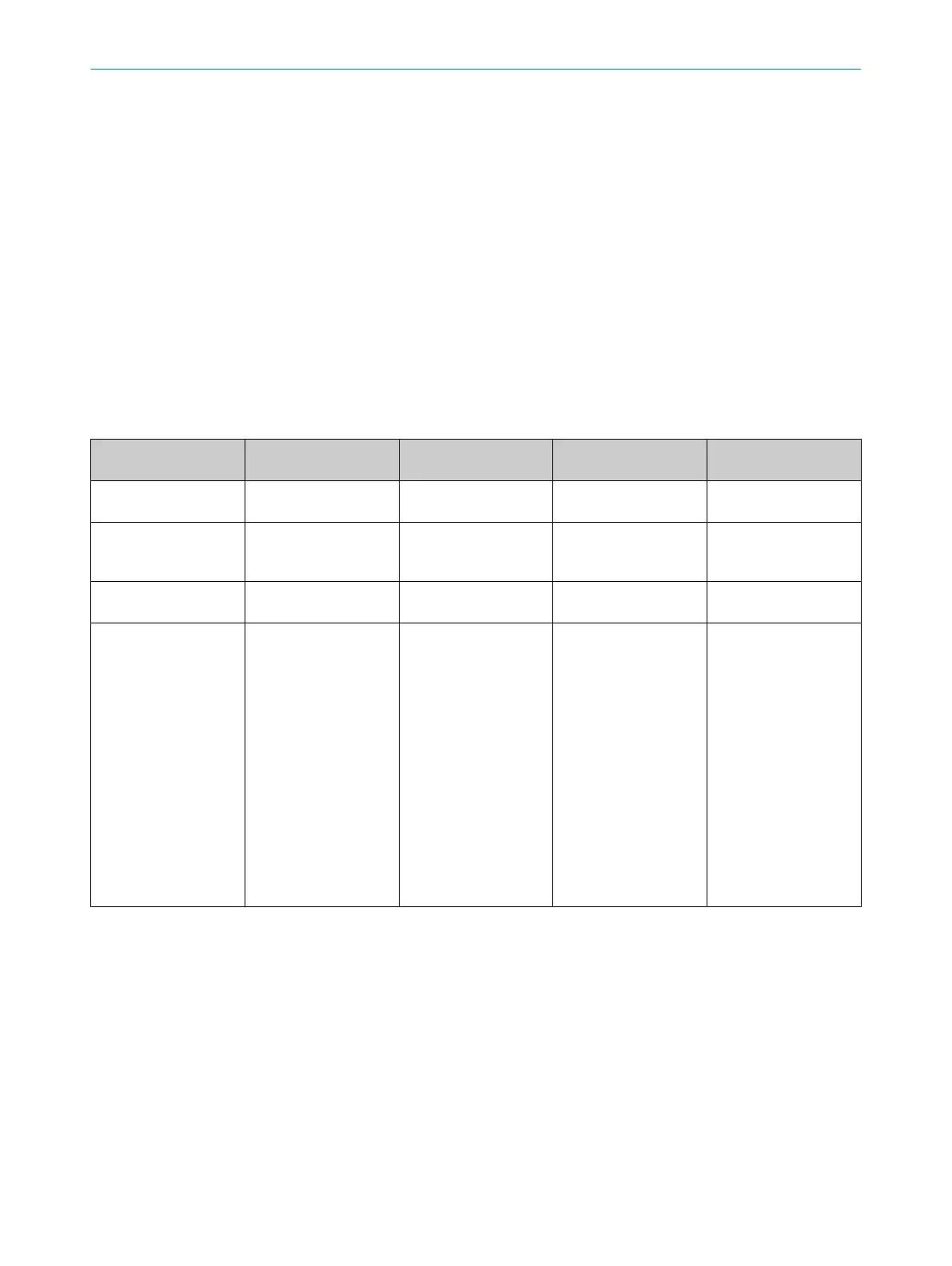

Table 2: Field types and their function

Protective field Contour as Reference

f

ield

Contour detection field Warning field

Safe switch off (accord‐

ing to ISO 13849-1)

Yes (PL d) Yes (PL d) Yes (PL d) No

Max. scanning range of

t

he safety laser scan‐

ner

3.0 m 3.0 m 3.0 m 10 m

Purpose Detection and protec‐

tion of people

Tamper protection Contour monitoring Functional use (not

safety application)

Description The protective field pro‐

tects the hazardous

area of a machine or

vehicle. As soon as the

electro-sensitive protec‐

tive device detects an

object in the protective

field, it switches the

associated safety out‐

puts to the OFF state.

This signal can be

passed to controllers

resulting in the danger‐

ous state coming to an

end, e.g. to stop the

machine or the vehicle.

The reference contour

field monitors a contour

of the environment. The

safety laser scanner

switches all safety out‐

puts to the OFF state if

a contour does not

match the set parame‐

ters, because, for

example, the mounting

situation of the safety

laser scanner were

changed.

The contour detection

field monitors a contour

of the environment. The

safety laser scanner

switches the associated

safety outputs to the

OFF state if a contour

does not match the set

parameters, because,

for example, a door or

flap is open.

The warning field moni‐

tors larger areas than

the protective field.

Simple switching func‐

tions can be triggered

with the warning field,

e.g. a warning light or

an acoustic signal can

be triggered if a person

approaches, even

before the person

enters the protective

field.

3.4 Example applications

Hazardous area protection

In ha

zardous area protection, people are detected if they stay in a defined area.

This type of protective device is suitable for machines, where it is possible to see a haz‐

ardous area completely from the reset pushbutton. When the hazardous area is

entered, a stop signal is triggered and starting is prevented.

3 P

RODUCT DESCRIPTION

14

O P E R A T I N G I N S T R U C T I O N S | nanoScan3 I/O 8024596/15VP/2019-11-15 | SICK

Subject to change without notice

Loading...

Loading...