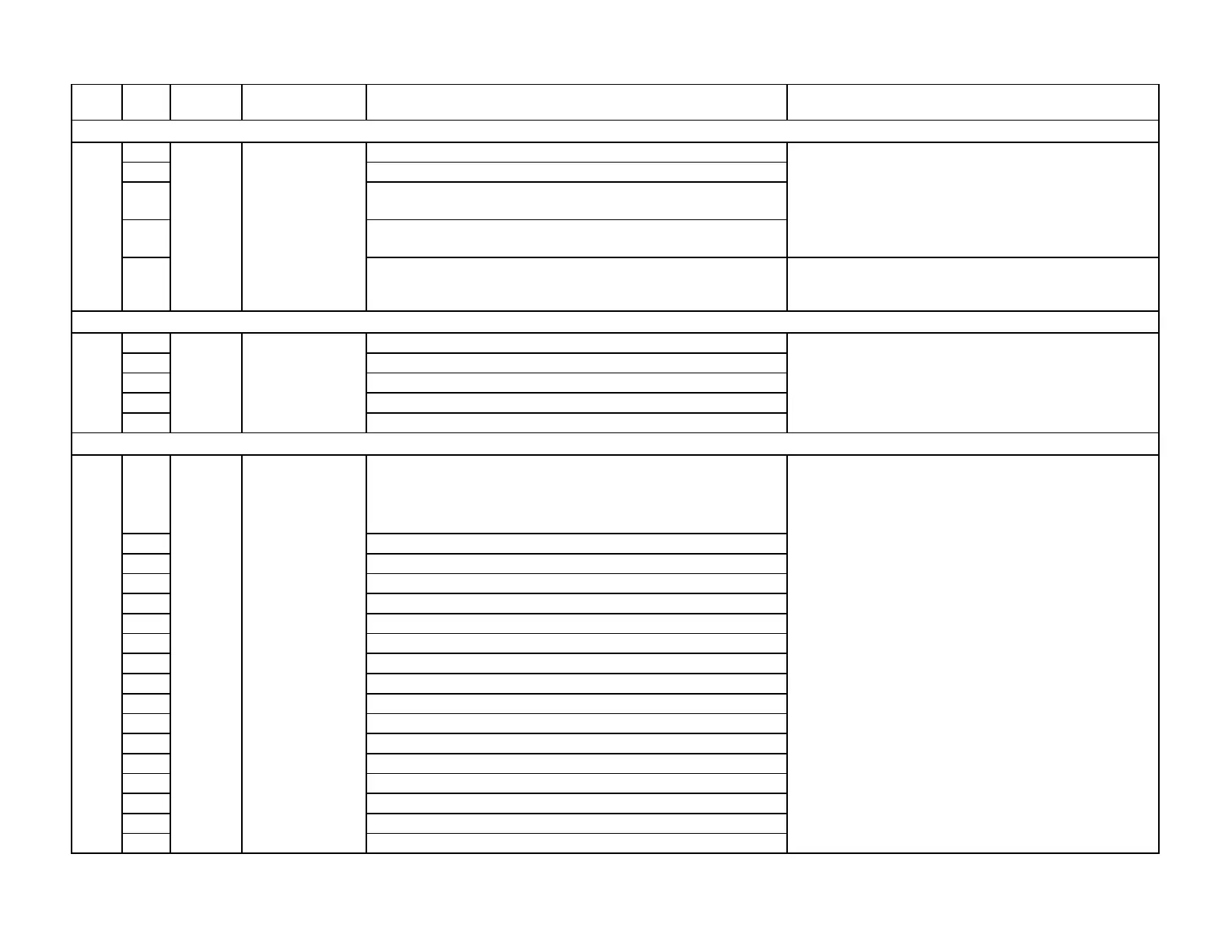

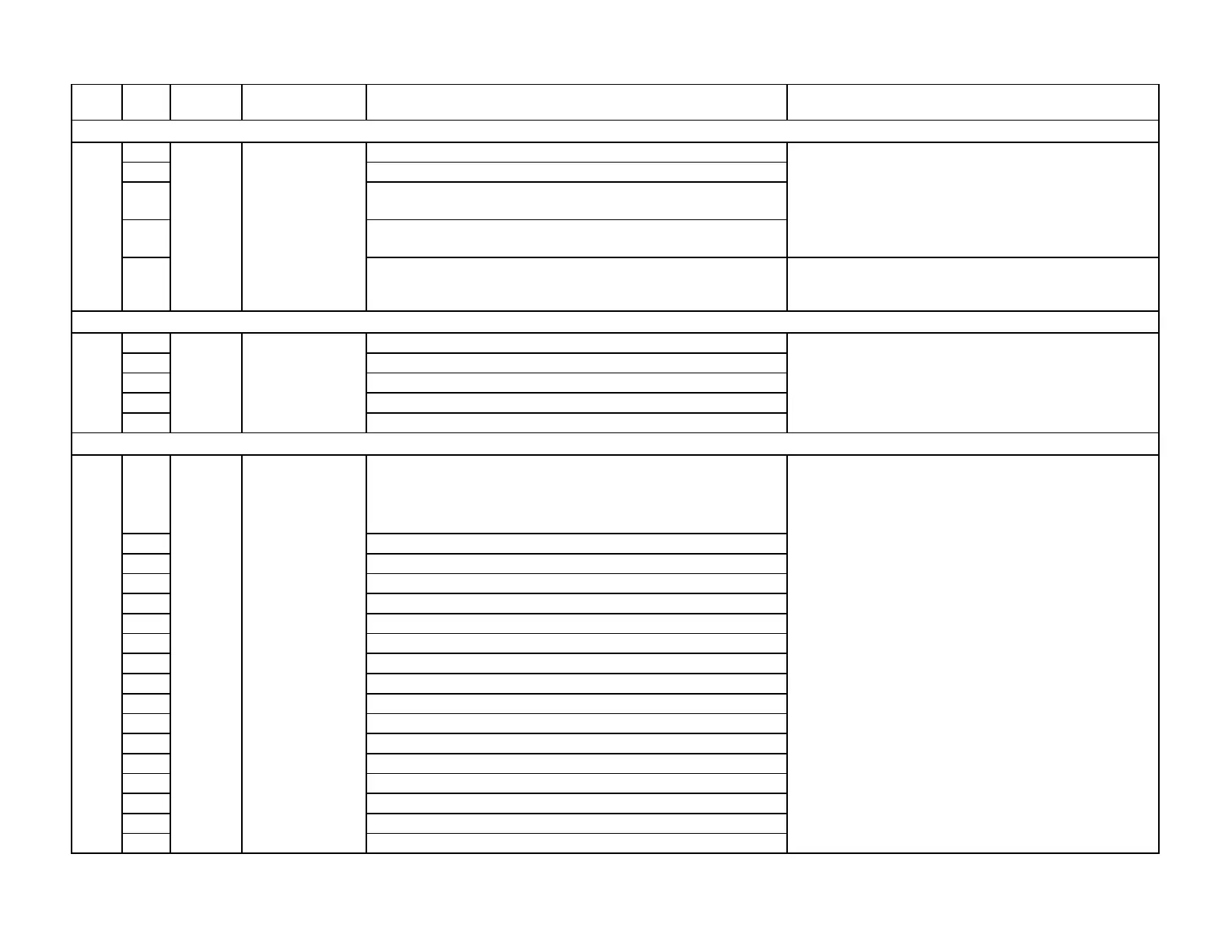

Device Display Meaning for the LMV5x System Corrective Action

Any # Fault during test of the flame signal amplifier

01 Fault during test of the flame signal amplifier

02

Crosstalk fault between test pin and flame signal amplifier

channel (with LMV52 FSV channel QRI... / QRB...)

03

Crosstalk fault between test pin and FSV channel ION (LMV52

only)

10

Monitoring of redundancy contact on external high-temperature

or flame safegaurd

Check the wiring and the parameters of the external

safety limit thermostat / external flame safeguard

including the redundancy contact.

Any # Fault internal hardware tests

01 Fault during test of the ignition relay

02 Fault during test of the safety relay

03 Fault during voltage supervision test

04 Relay voltage not switched off after reset

Any #

Basic unit has detected an improper circuit at one of the

outputs, a faulty diode, or a short-circuit in the power supply of

the contact feedback network. The diagnostic code indicates

the input affected.

01 Load controller on / off

02 Fan contact

03 Selection of oil-firing

04 Selection of gas-firing

05 Reset

06 Pressure switch oil maximum

07 Pressure switch oil minimum

08 Pressure switch valve proving

09 Safety valve oil feedback

0A Fuel valve 1 oil feedback

0B Fuel valve 2 oil feedback

0C Fuel valve 3 oil feedback

0D Safety valve gas feedback

0E Fuel valve 1 gas feedback

0F Fuel valve 2 gas feedback

10 Pilot valve gas feedback

Fault with Base Unit (LMV5)

Internal Fault

Basic Unit

1) Check connections of the neutrals to all of the

connected switches, valves, etc...

2) Check for inductive loads that cause voltage to be

present on the terminal after the LMV de-energizes the

terminal. If voltage exists on an output terminal, such as

a fuel valve, after the LMV de-energizes the terminal,

this will cause a fault. Voltage must drop to zero on the

terminal within about 10 ms after the terminal is de-

energized.

If fault occurs sporadically, reduce electrical noise.

If fault occurs continuously, replace LMV5.

06 LMV5

Internal Fault

Basic Unit

Fault with devices or wiring connected to the Base Unit (LMV5)

LMV5 /

Flame

Dect.

Fault Flame

Detector Test

05

Fault with Flame scanner (QRI) or Base Unit (LMV5)

10

If fault occurs sporadically: Improve shielding / isolation

of flame detector wires. High LMV5 temperatures can

also cause this fault. If fault occurs constantly: Lower

LMV5 temperature, replace flame detector, or replace

LMV5.

Devices

conn. to

LMV5

Section 7 Page 24 SCC Inc.

Loading...

Loading...