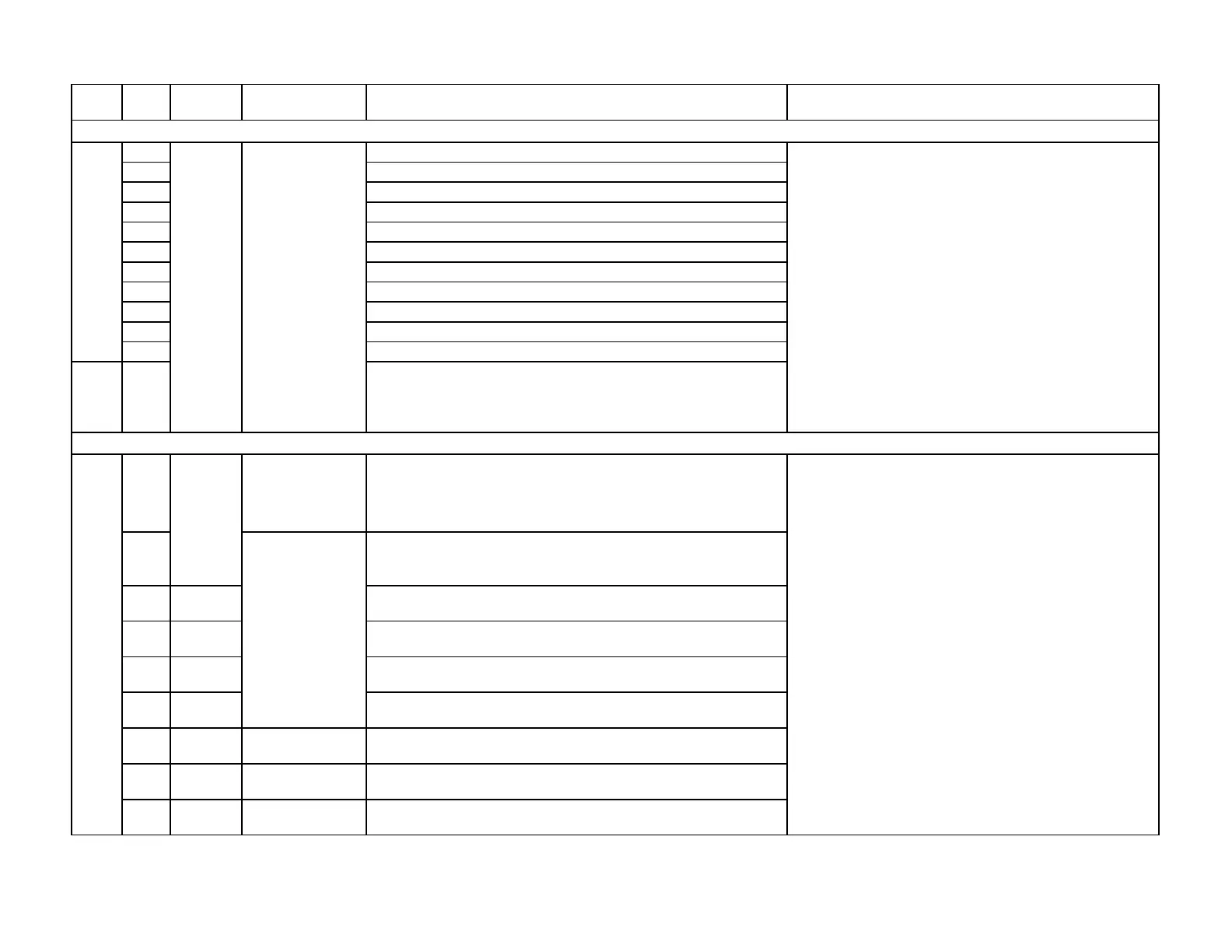

Device Display Meaning for the LMV5x System Corrective Action

11 Safety chain burner flange

12 Safety relay feedback

13 Pressure switch gas minimum

14 Pressure switch gas maximum

15 Ignition transformer feedback

16 Fan pressure switch

17 Start release oil

18 Heavy oil direct start

19 Load controller open

1A Load controller closed

1B Start release gas

11 01

Basic unit has detected a short-circuit in the contact feedback

network

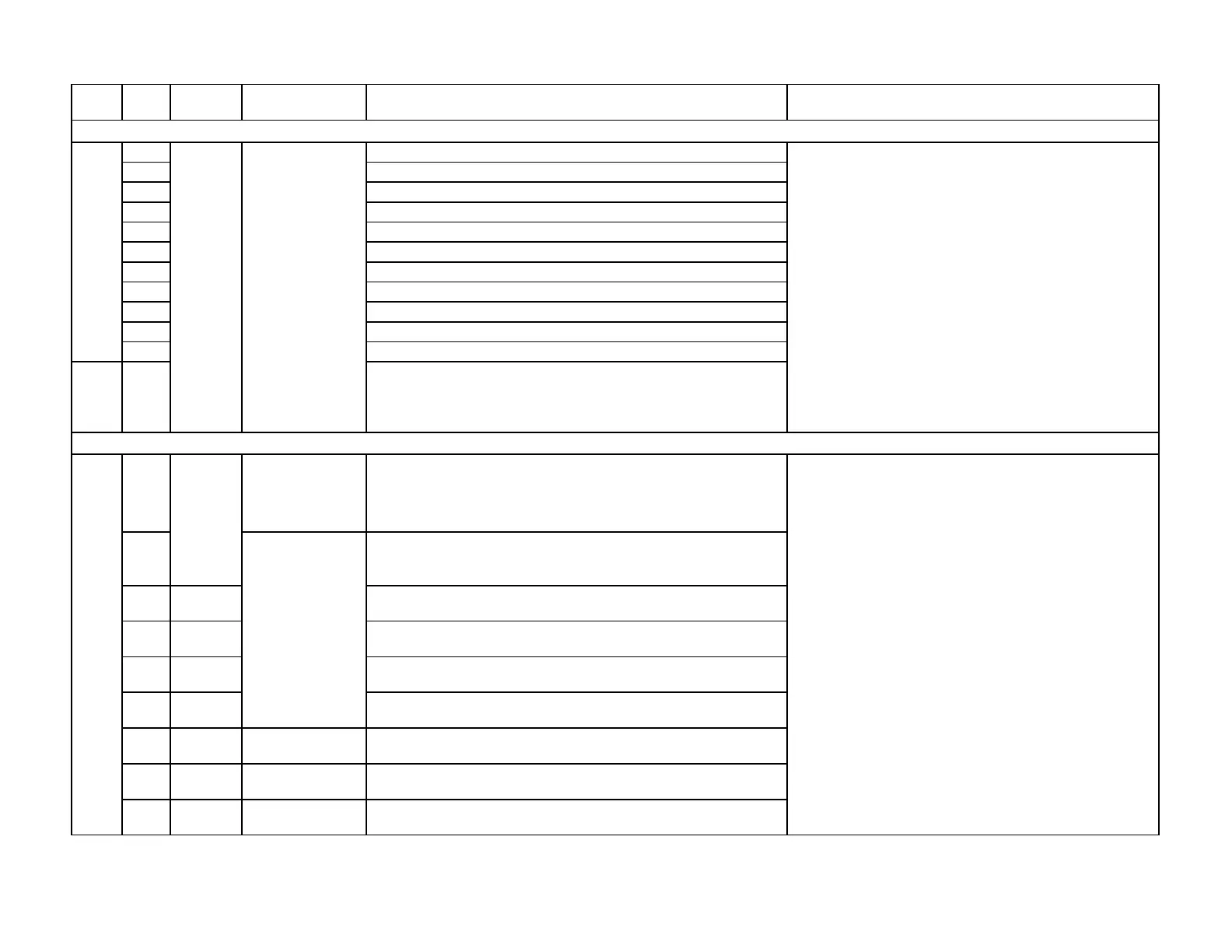

Any #

Fault Positioning

Actuator or Fan

Speed Not

Reached

LMV5 has detected a positioning error on one or several

actuators, or the VSD module if equipped.

01-3F

The diagnostic value is made up of the following faults or their

combinations (the individual diagnostic codes are added up in

01

Air

Positioning fault air actuator

02

Active

Positioning fault fuel actuator

04

Aux1

Positioning fault auxiliary actuator 1

08

Aux2

Positioning fault auxiliary actuator 2

10

VSD

Fan Speed Not

The fan in combination with the VSD has not reached the

20

Aux3

Fault Positioning

Positioning fault auxiliary actuator 3

40

VSD

Fan Speed Not

The difference of actual value and speed setpoint is greater

than permitted by parameter

If error occurs on one actuator only :

1) Ensure torque requirements of dampers / valves are

less than actuator output. Actuators running over rated

50% duty cycle may have significantly reduced torque

output.

2) Verify that no damper / valve is bound.

3) If 1 and 2 do not solve the problem: replace actuator.

If error occurs on multiple actuators (01-3F) :

1) Verify that the CANBus wiring is correct.

2) Verify that shields (screens) on CANBus cables are

connected properly.

If error occurs on VSD :

1) Check speed sensor on motor for correct installation,

especially gap between sensor and wheel.

2) Check for filters, damping, and / or delays on the

input signal to the VSD. The VSD should respond to

the input signal in a linear fashion. Extend VSD and

LMV5 ramp times.

15

Fault Positioning

Actuator

Fault with Connected actuators or VSD

Actuator /

VSD

Control

10

Devices

conn. to

LMV5

Internal Fault

Basic Unit

1) Check connections of the neutrals to all of the

connected switches, valves, etc...

2) Check for inductive loads that cause voltage to be

present on the terminal after the LMV de-energizes the

terminal. If voltage exists on an output terminal, such as

a fuel valve, after the LMV de-energizes the terminal,

this will cause a fault. Voltage must drop to zero on the

terminal within about 10 ms after the terminal is de-

energized.

Fault with devices or wiring connected to the Base Unit (LMV5)

Section 7 Page 25 SCC Inc.

Loading...

Loading...