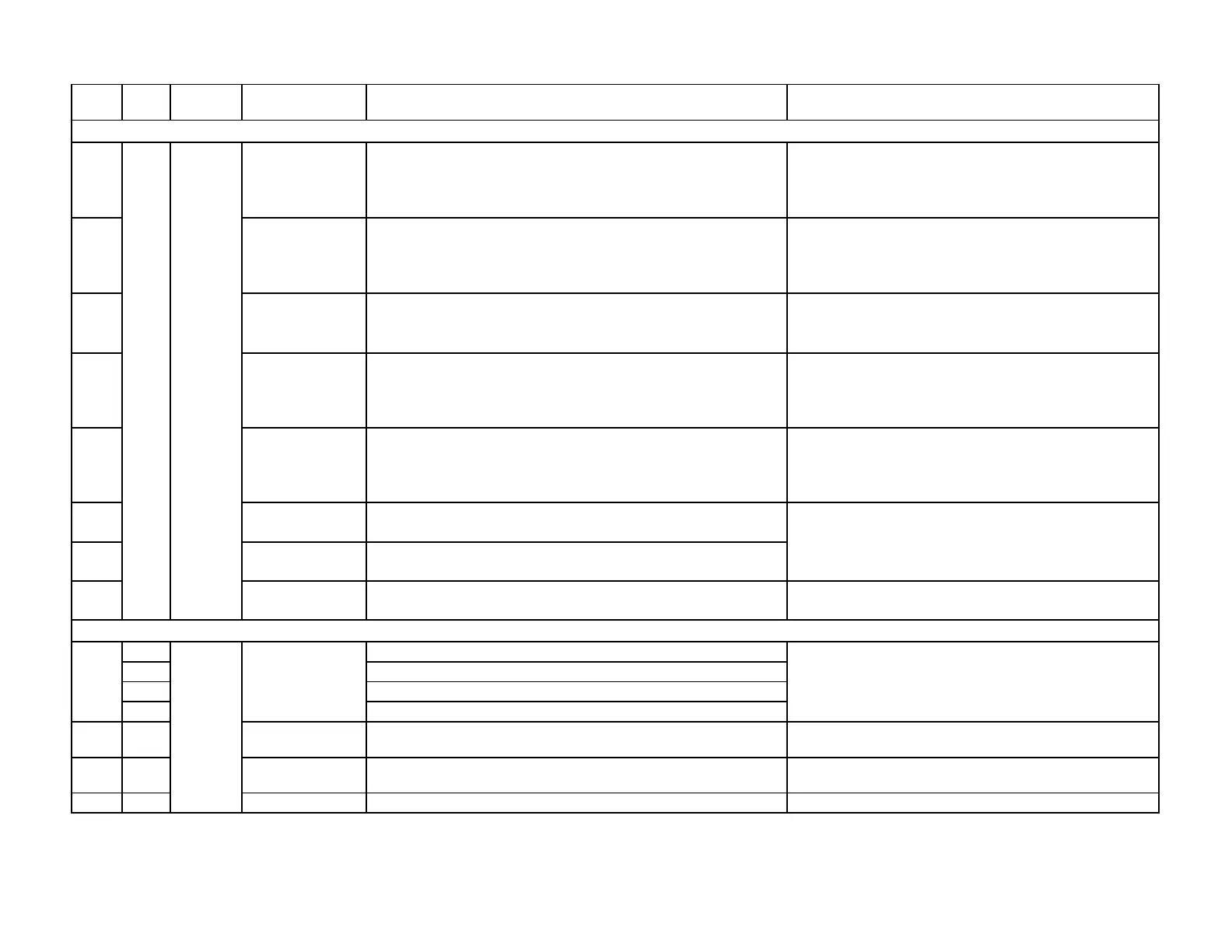

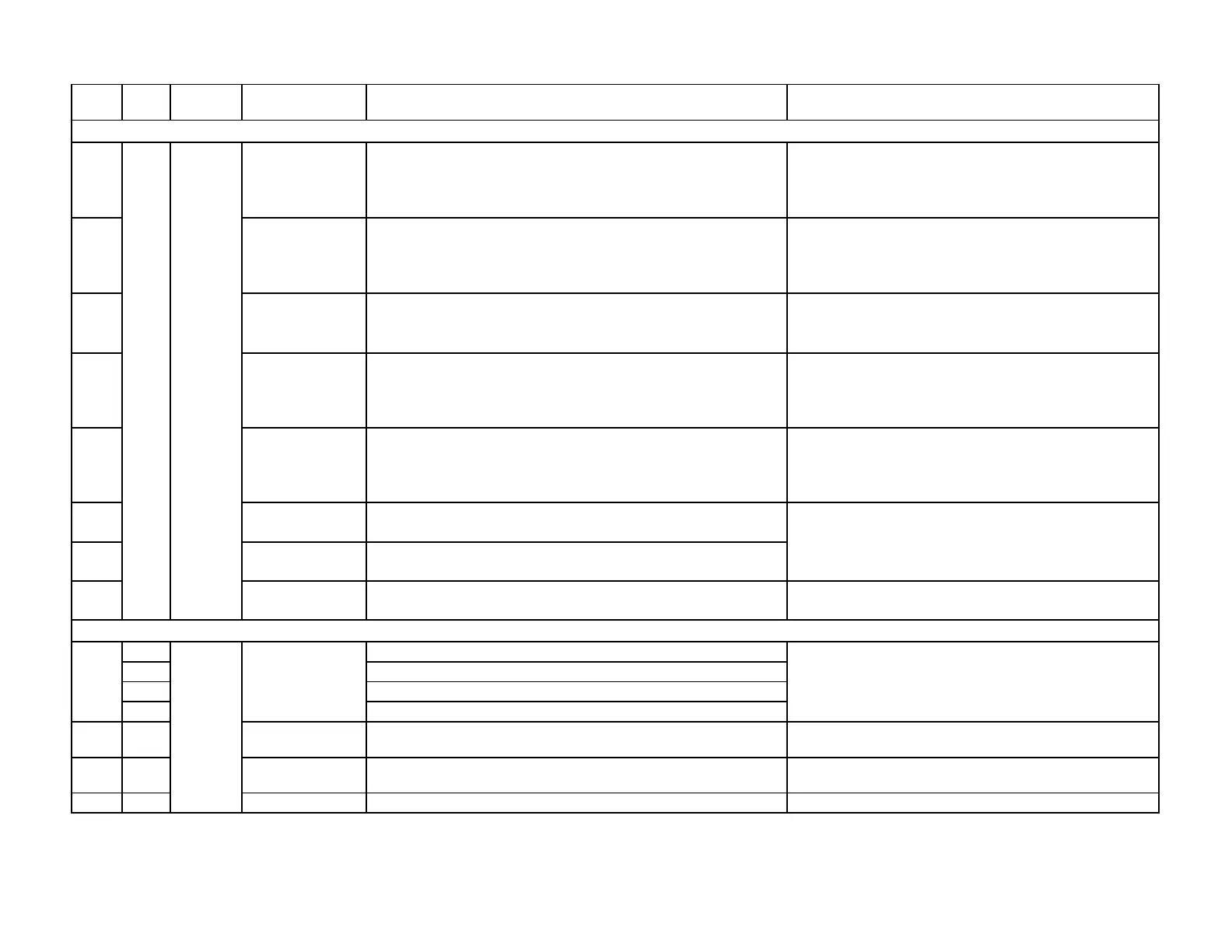

Device Display Meaning for the LMV5x System Corrective Action

31

Gas Pressure

at Valve proving:

Valve on Gas

Side leaking

PS(M)-VP (Pressure Switch Valve Proving) has detected

pressure between the gas valves during the atmospheric test.

Switch opened when should have been closed.

1) Bubble test gas valve to ensure that the upstream

valve is not leaking. If leaking, replace valve.

2) Ensure that the setpoint of the PS(M)-VP is 50% of

the pressure upstream of V1 (upstream valve).

32

No Gas Pressure

Valve Proving:

Valve on Burner

Side leaking

PS(M)-VP (Pressure Switch Valve Proving) has detected the

absence of pressure between the gas valves during the

pressure test. Switch closed when should have been open.

1) Bubble test gas valve to ensure that the downstream

valve is not leaking. If leaking, replace valve.

2) Ensure that the setpoint of the PS(M)-VP is 50% of

the pressure upstream of V1 (upstream valve).

33

Oil Pressure on

although Oil

Pump off

Low oil pressure switch is closed when oil pump is not running.

1) Configure oil train so that low oil pressure switch is

off when the oil pump is not running.

2) Check to ensure switch is wired Normally Open.

34

Oil Pressure

below Minimum

Low oil pressure switch is open when oil pump is running.

1) Ensure oil pressure exists at the switch when the oil

pump is running. Adjust pressure reg. if needed.

2) Check to ensure switch is wired Normally Open.

Check setpoint of switch.

35

Oil Pressure

above Maximum

High oil pressure switch is open.

1) Ensure excess oil pressure is not present at the

switch. Adjust pressure reg. if needed.

2) Check to ensure switch is wired Normally Closed.

Check setpoint of switch.

36

No Start Release

for Oil

Switches wired to the start release oil terminal (typically the

atomizing media PS) are not closed when anticipated.

37

No direct Heavy

Oil direct start

Switches wired to the direct start heavy oil terminal are not

closed when anticipated.

38

Lack of Gas

Program

Shortage-of-gas program in progress.

1) If repetition counter is enabled (outside North

America), the LMV is waiting for gas pressure to return.

Any # Parameter of max. safety time faulty

01 Fault with timer1

02 Fault with timer2

03 Fault with timer3

3A Any #

No Burner ID

No burner identification defined

Enter a unique burner Identification. Typically the

3B Any #

No Service

No service password defined Enter a valid service password.

3F Any # Error-free The LMV5 is error-free. None

If fault occurs continuously, replace LMV5.

Fault with Base Unit (LMV5)

Any #

Internal Fault

Basic Unit

1) Check setpoint of switches.

2) Ensure switches are closing and opening at the

correct times (see sequence diagram).

39

Devices

conn. to

LMV5

Fault with devices or wiring connected to the Base Unit (LMV5)

LMV5

Section 7 Page 33 SCC Inc.

Loading...

Loading...