Movement Control Commands

3.1 The coordinate system

04.07

3-53

© Siemens AG 2007 All rights reserved

SINUMERIK 802D sl/840D/840D sl/840Di/840Di sl/810D ISO Milling (PGM) -- 04.07 Edition

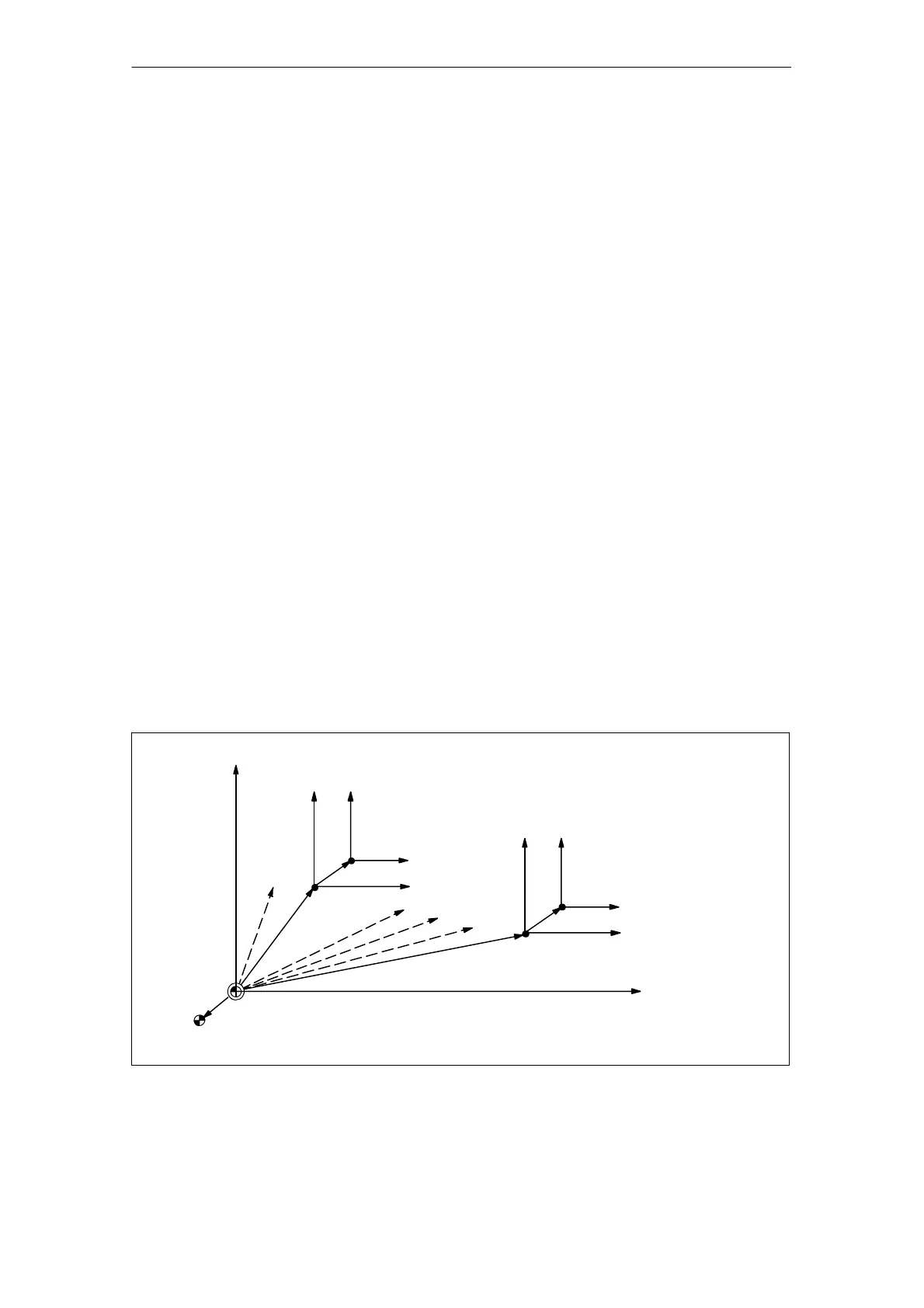

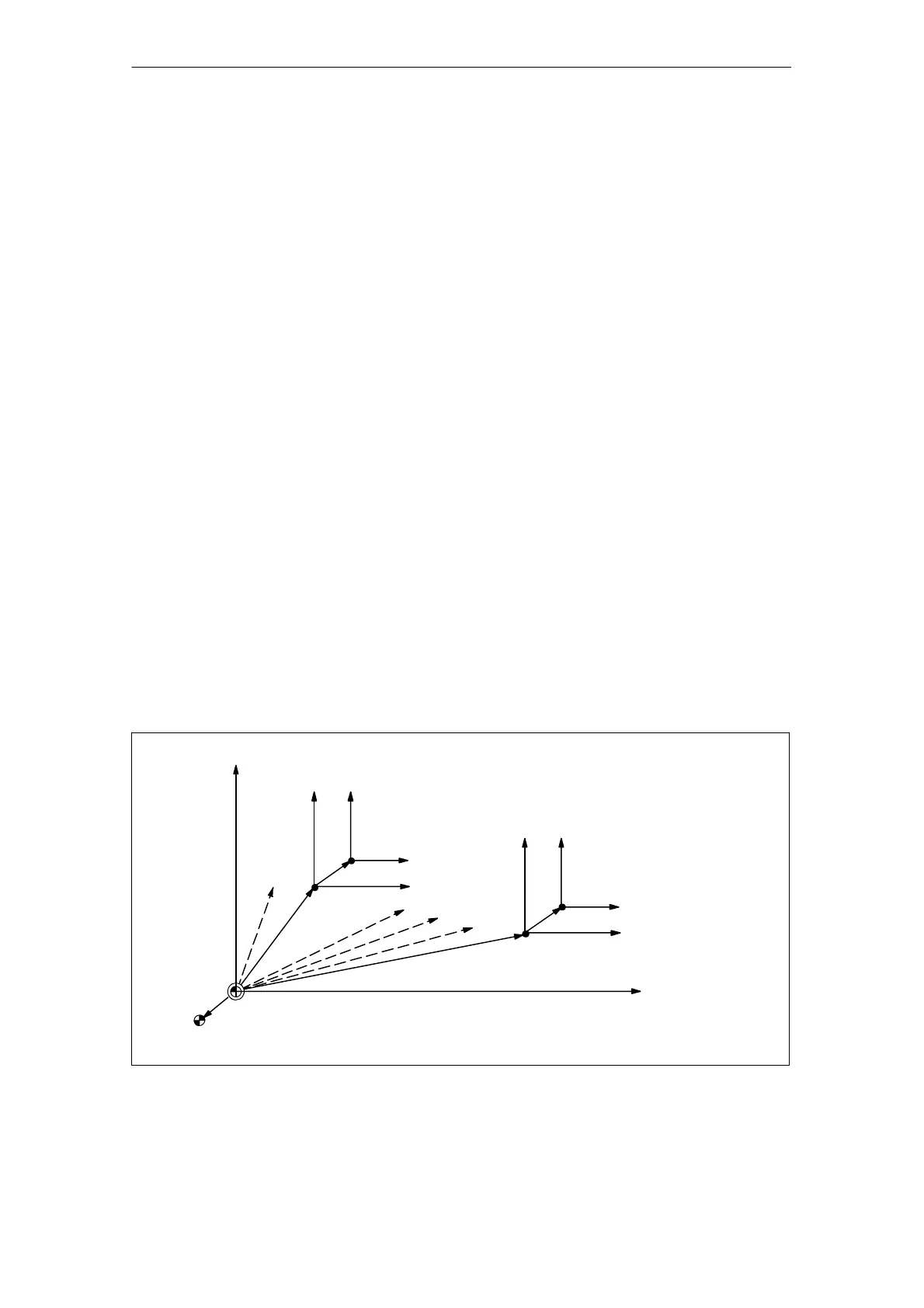

For easier programming, a kind of sub--workpiece coordinate system can be set

whenever a program is created in a workpiece coordinate system. Such a sub--

coordinate system is called a local coordinate system.

Format

G52 X... Y... Z... ; Local coordinate system set

G52 X0 Y0 Z0 ; Local coordinate system cancel

X, Y, Z: Local coordinate system origin

Explanations

A local coordinate system can be set in all the workpiece coordinate systems (G54

to G59) by specifying G52 X... Y... Z...;. Within the workpiece coordinate system,

the origin of each local coordinate system is set to the position determined by X, Y,

and Z.

Whenever a local coordinate system is set, the motion commands subsequently

commanded in the absolute mode (G90) correspond to the coordinate values wit-

hin the local coordinate system. By determining the G52 command through the

zero point of a new local coordinate system in the workpiece coordinate system,

the local coordinate system can be changed.

Match the zero point of the local coordinate system with that of the workpiece coor-

dinate system in order to cancel the local coordinat e system and to determine the

coordinate value within the workpiece coordinate syst em.

The position value displayed as the coordinate value of workpiece coordinate sy-

tem refers to the zero point of workpiece coordinate system even if the local coor-

dinate system is set by specifying G52.

Machine coordinate system origin

Reference point

(Local coordinate system)

(G55 : Workpiece coordinate system 2)

(Local coordinate system)

(G59 : Workpiece coordinate system 6)

G54

G56

G57

G58

(Machine coordinate system)

Fig. 3-9 Setting the local coordinate system

Loading...

Loading...