Path traversing behavior

8.6 Repositioning to a contour (REPOSA, REPOSL, REPOSQ, REPOSQA, REPOSH, REPOSHA, DISR,

DISPR, RMI, RMB, RME, RMN)

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

483

Approaching with a new tool

The following applies if you have stopped the program run due to tool breakage:

When the new D number is programmed, the machining program is continued with modified

tool offset values at the repositioning point.

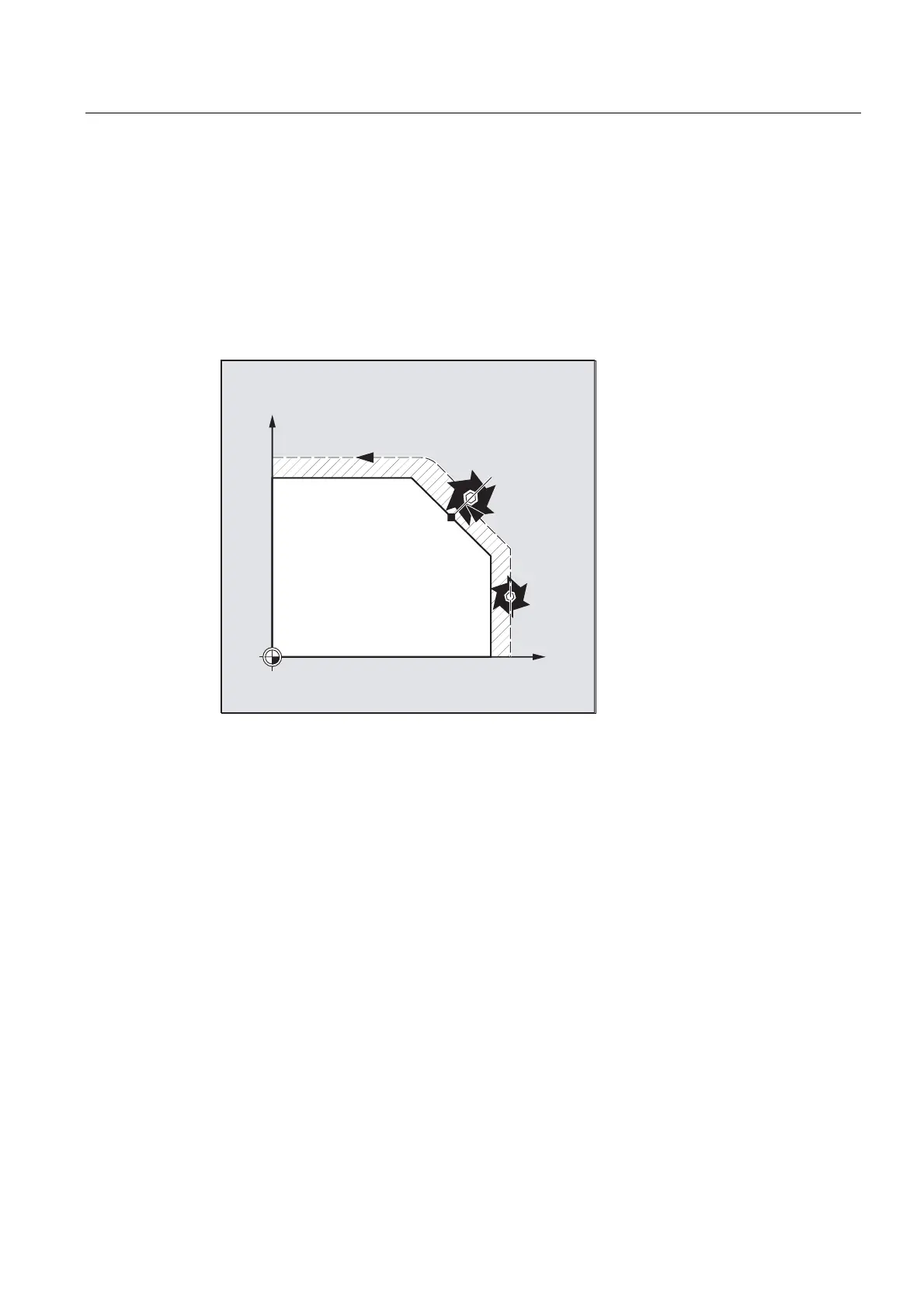

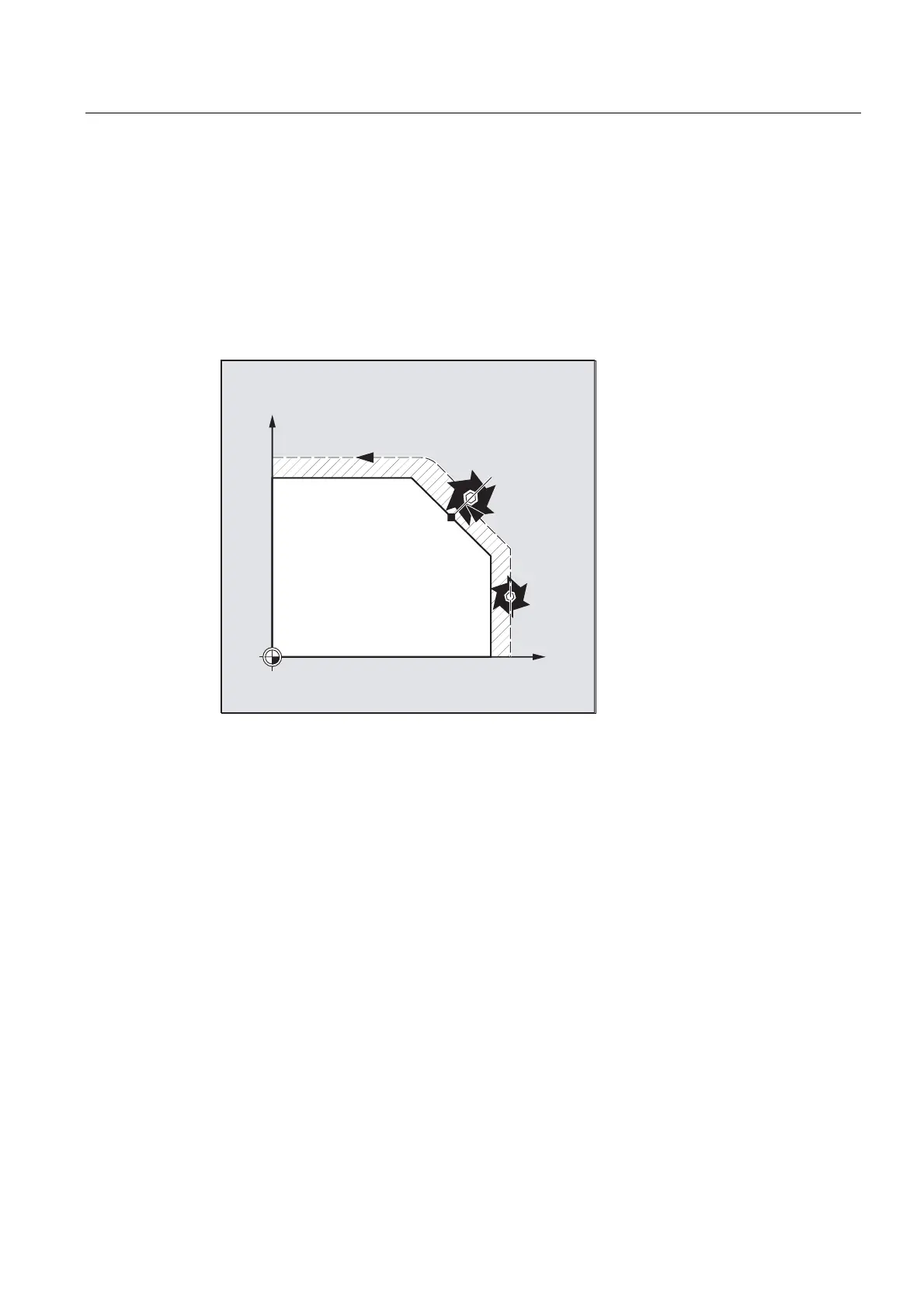

Where tool offset values have been modified, it may not be possible to reapproach the

interruption point. In such cases, the point closest to the interruption point on the new

contour is approached (possibly modified by DISPR).

<

;

Approach contour

The motion with which the tool is repositioned on the contour can be programmed. Enter

zero for the addresses of the axes to be traversed.

The

REPOSA, REPOSQA and REPOSHA commands automatically reposition all axes. Individual

axis names need not be specified.

When the commands

REPOSL, REPOSQ and REPOSH are programmed, all geometry axes are

traversed automatically, i.e. they need not be named in the command. All other axes must be

specified in the commands.

Loading...

Loading...