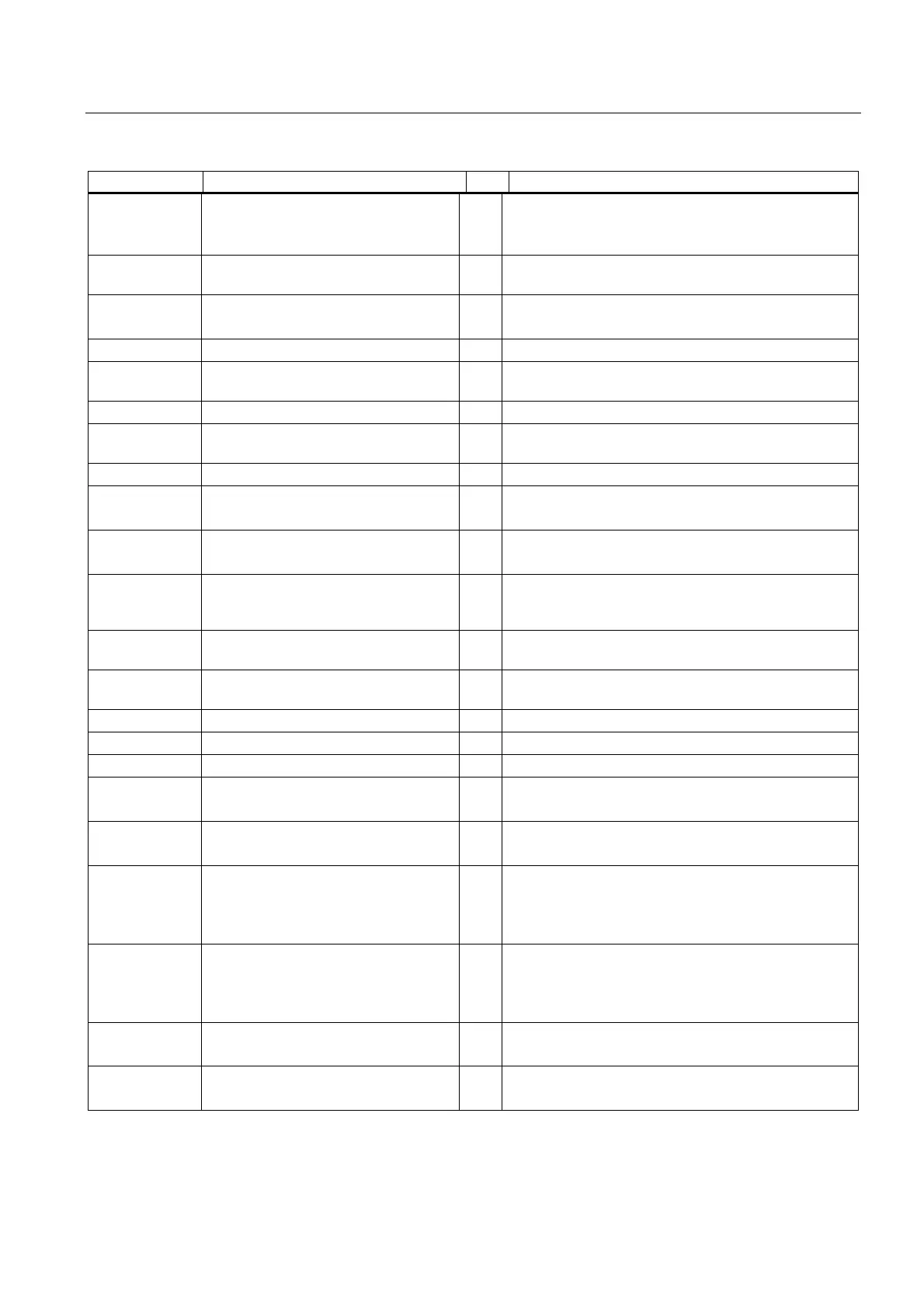

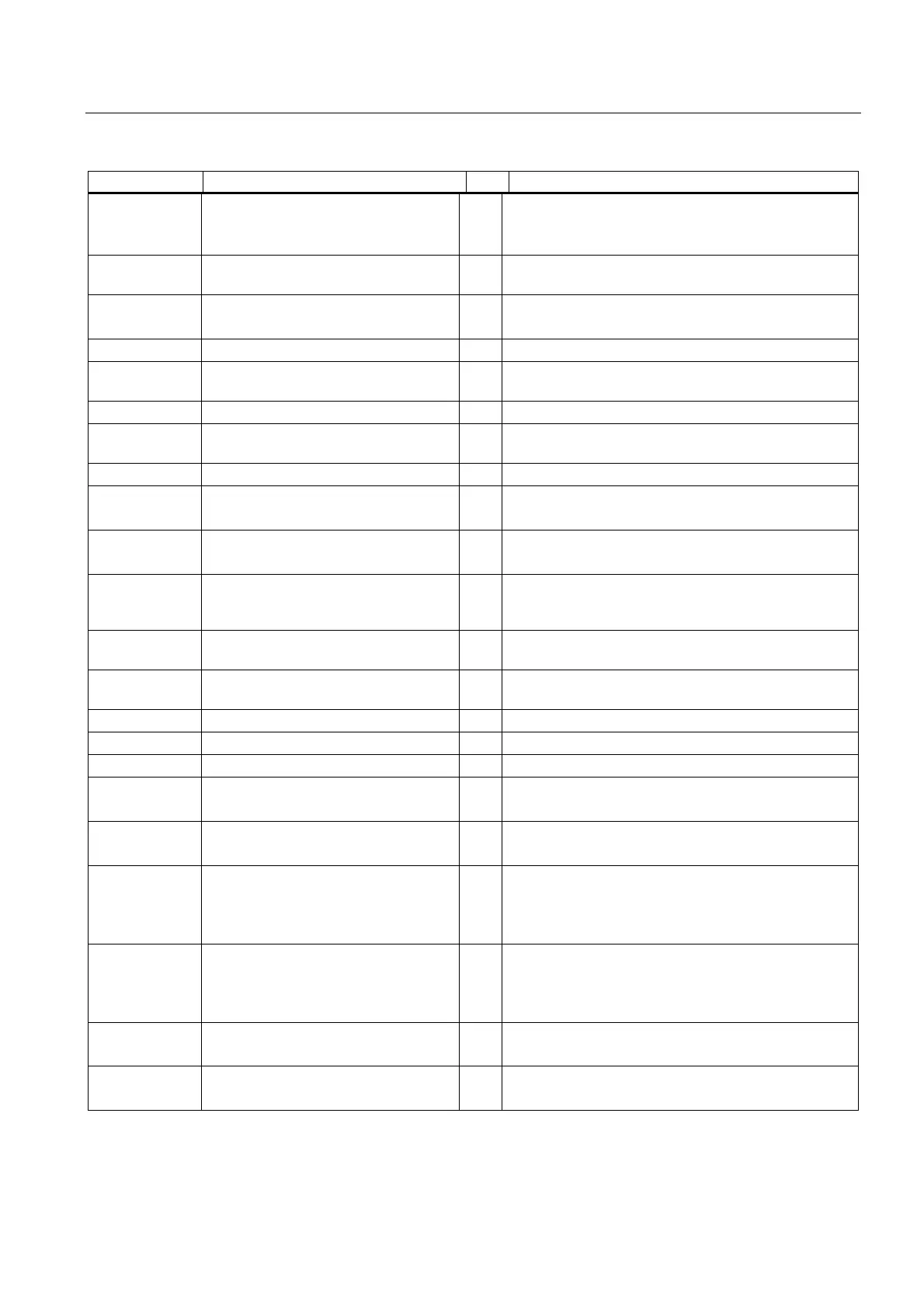

Tables

16.1 Instructions

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

749

Operation Meaning W

1)

Description see

2)

SETM Setting of markers in dedicated channel PGAsl

Program coordination (INIT, START, WAITM, WAITMC,

WAITE, SETM, CLEARM) (Page 106)

SETMS Reset to the master spindle defined in

machine data

SETMS(n) Set spindle n as master spindle

PGsl

SETMTH Set master toolholder number

FBW

SETPIECE Set piece number for all tools assigned

to the spindle

FBW

SETTA Activate tool from wear group

FBW

SETTCOR Modification of tool components taking

all general conditions into account

FB1(W1)

SETTIA Deactivate tool from wear group

FBW

SF Starting point offset for thread cutting m

PGsl

SIN Sine (trigon. function)

PGAsl

Arithmetic functions (Page 63)

SIRELAY Activate the safety functions

parameterized with SIRELIN,

SIRELOUT, and SIRELTIME

FBSIsl

SIRELIN Initialize input variables of function

block

FBSIsl

SIRELOUT Initialize output variables of function

block

FBSIsl

SIRELTIME Initialize timers of function block

FBSIsl

SLOT1 Milling pattern cycle, groove on a circle

BHDsl/BHFsl

SLOT2 Milling pattern cycle, circular groove

BHDsl/BHFsl

SOFT Soft path acceleration m

PGsl

SOFTA Activate soft axis acceleration for the

programmed axes

PGsl

SON Nibbling ON m

PGAsl

Punching and nibbling on or off (SPOF, SON, PON,

SONS, PONS, PDELAYON, PDELAYOF, PUNCHACC)

(Page

647)

SONS Nibbling ON in interpolation cycle m

PGAsl

Punching and nibbling on or off (SPOF, SON, PON,

SONS, PONS, PDELAYON, PDELAYOF, PUNCHACC)

(Page 647)

SPATH

3)

Path reference for FGROUP axes is arc

length

m

PGAsl

Settable path reference (SPATH, UPATH) (Page 257)

SPCOF Switch master spindle or spindle(s)

from position control to speed control

m

PGsl

Loading...

Loading...