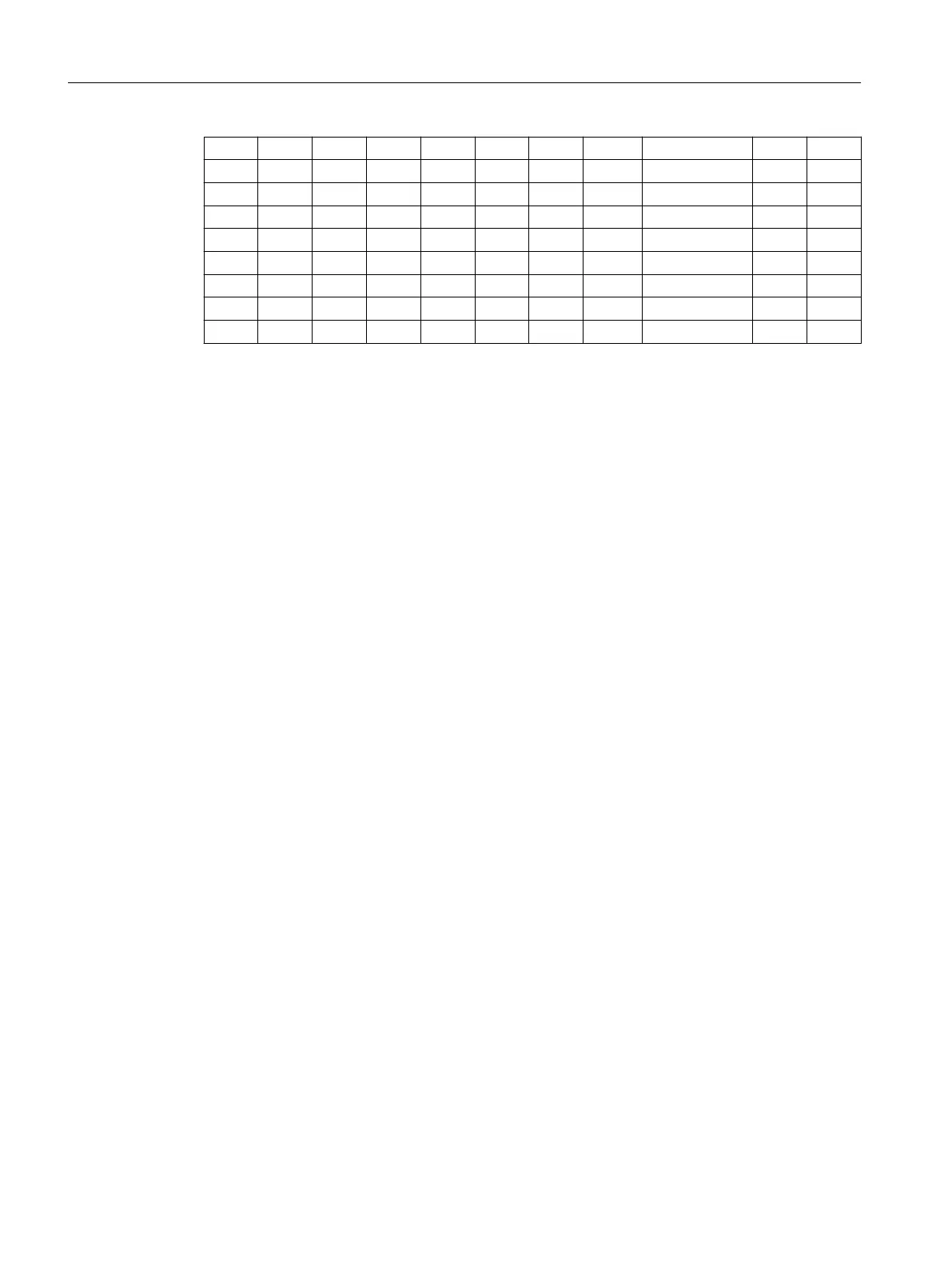

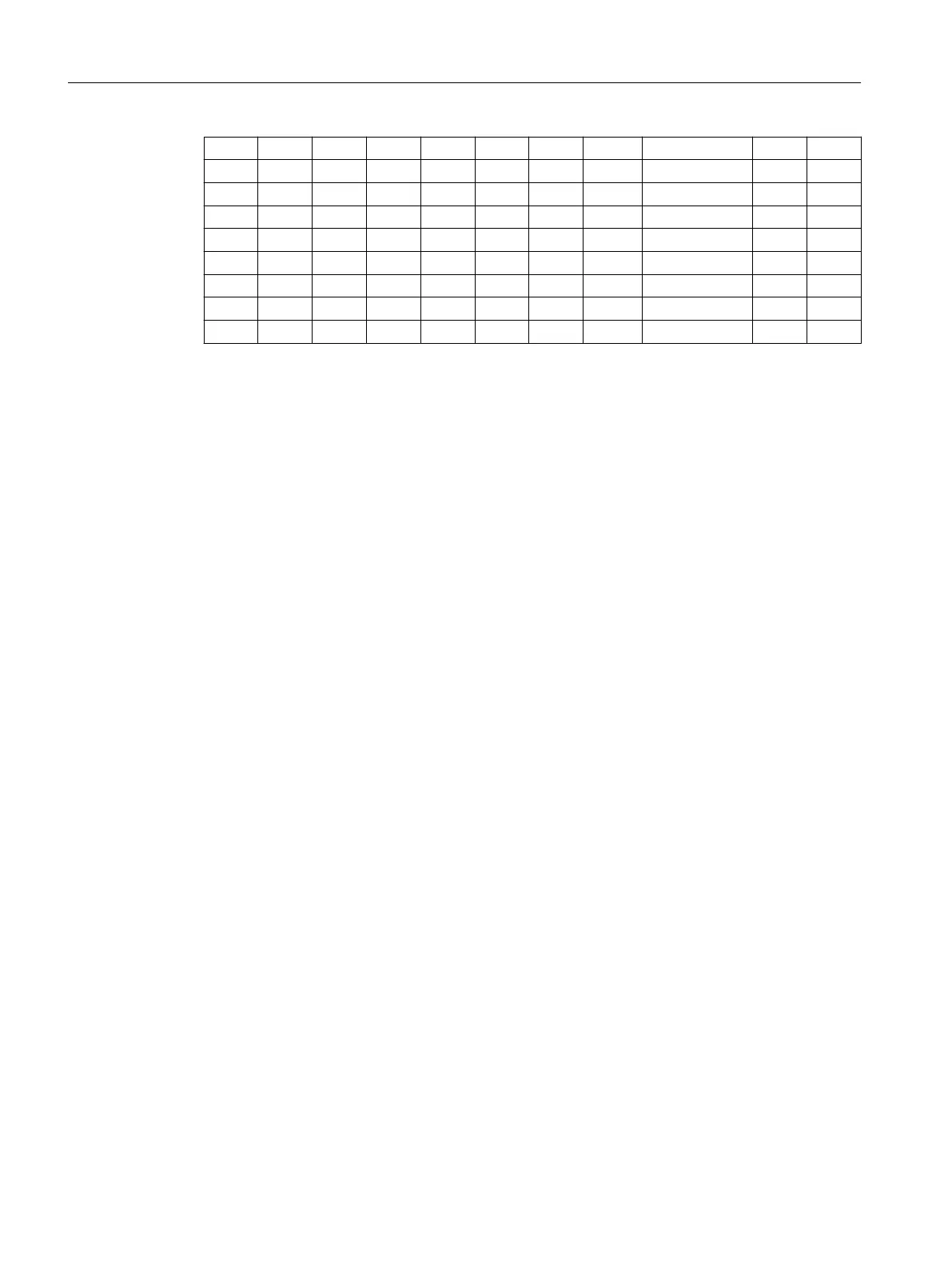

0 2 11 20 150 30 110 -1111 104.0362435 0 0

1 3 11 30 110 30 65 0 90 0 0

2 4 13 30 65 45 50 0 180 45 65

3 5 11 45 50 70 50 0 0 0 0

4 6 11 70 50 85 40 0 146.3099325 0 0

5 7 11 85 40 90 30 0 116.5650512 0 0

6 0 11 90 30 90 0 0 90 0 0

0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0

Explanation of the column contents:

(0) Pointer to next contour element (to the row number of that column)

(1) Pointer to previous contour element

(2) Coding the contour mode for motion

Possible values for X = abc

a = 10

2

G90 = 0 G91 = 1

b = 10

1

G70 = 0 G71 = 1

c = 10

0

G0 = 0 G1 = 1 G2 = 2 G3 = 3

(3), (4) Starting point of contour elements

(3) = abscissa, (4) = ordinate of the current plane

(5), (6) Starting point of the contour elements

(5) = abscissa, (6) = ordinate of the current plane

(7) Max/min indicator: Identifies local maximum and minimum values on the contour

(8) Maximum value between contour element and abscissa (for longitudinal machin‐

ing) or ordinate (for face cutting). The angle depends on the type of machining

programmed.

(9), (10) Center point coordinates of contour element, if it is a circle block.

(9) = abscissa, (10) = ordinate

Example 2

Generating a contour table with

● Name KTAB

● Max. 92 contour elements (circles, straight lines)

● Operating mode: Longitudinal turning, external machining

● Preparation, forward and backward

Work preparation

3.24 User stock removal programs

NC programming

1012 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...