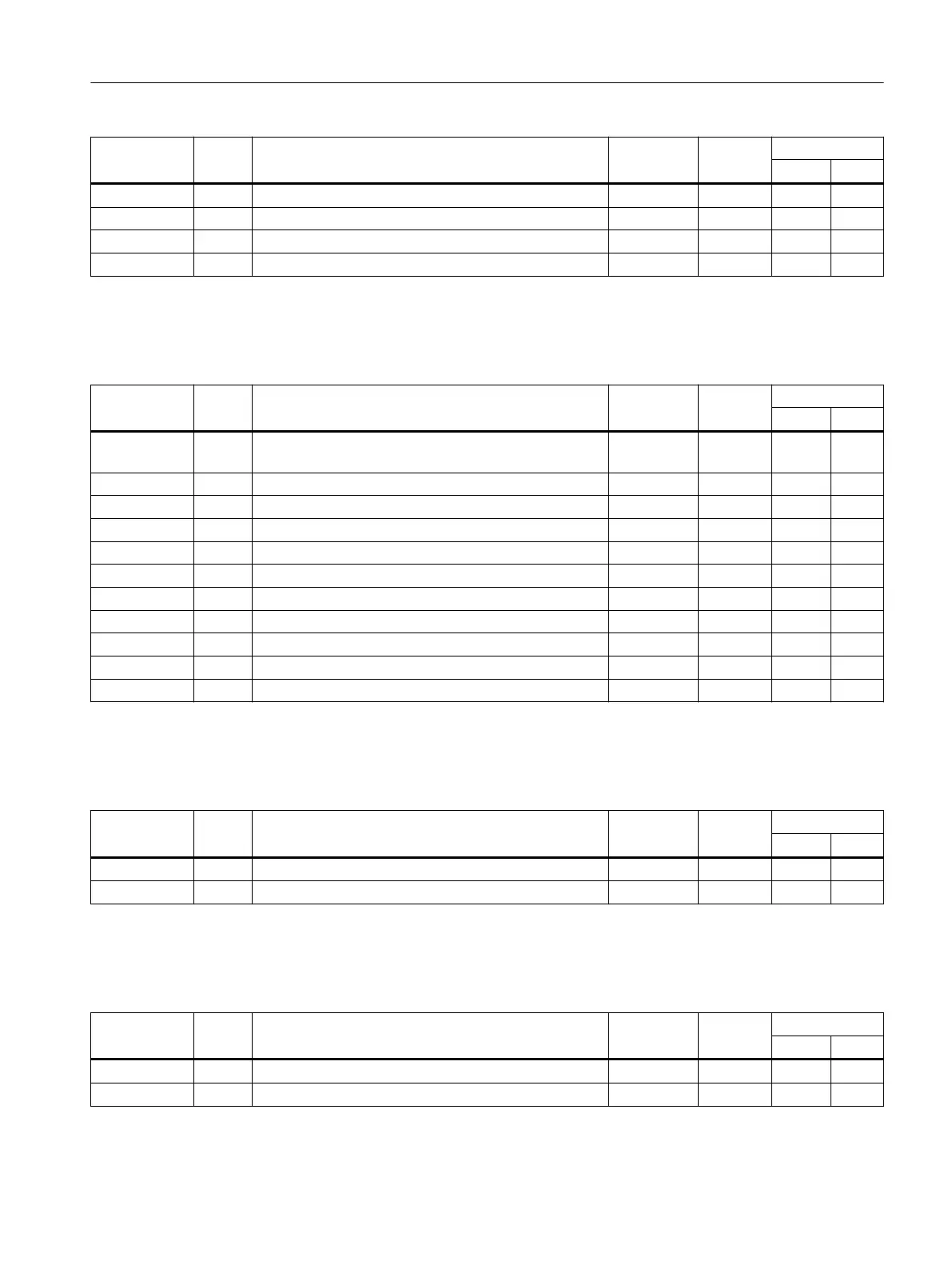

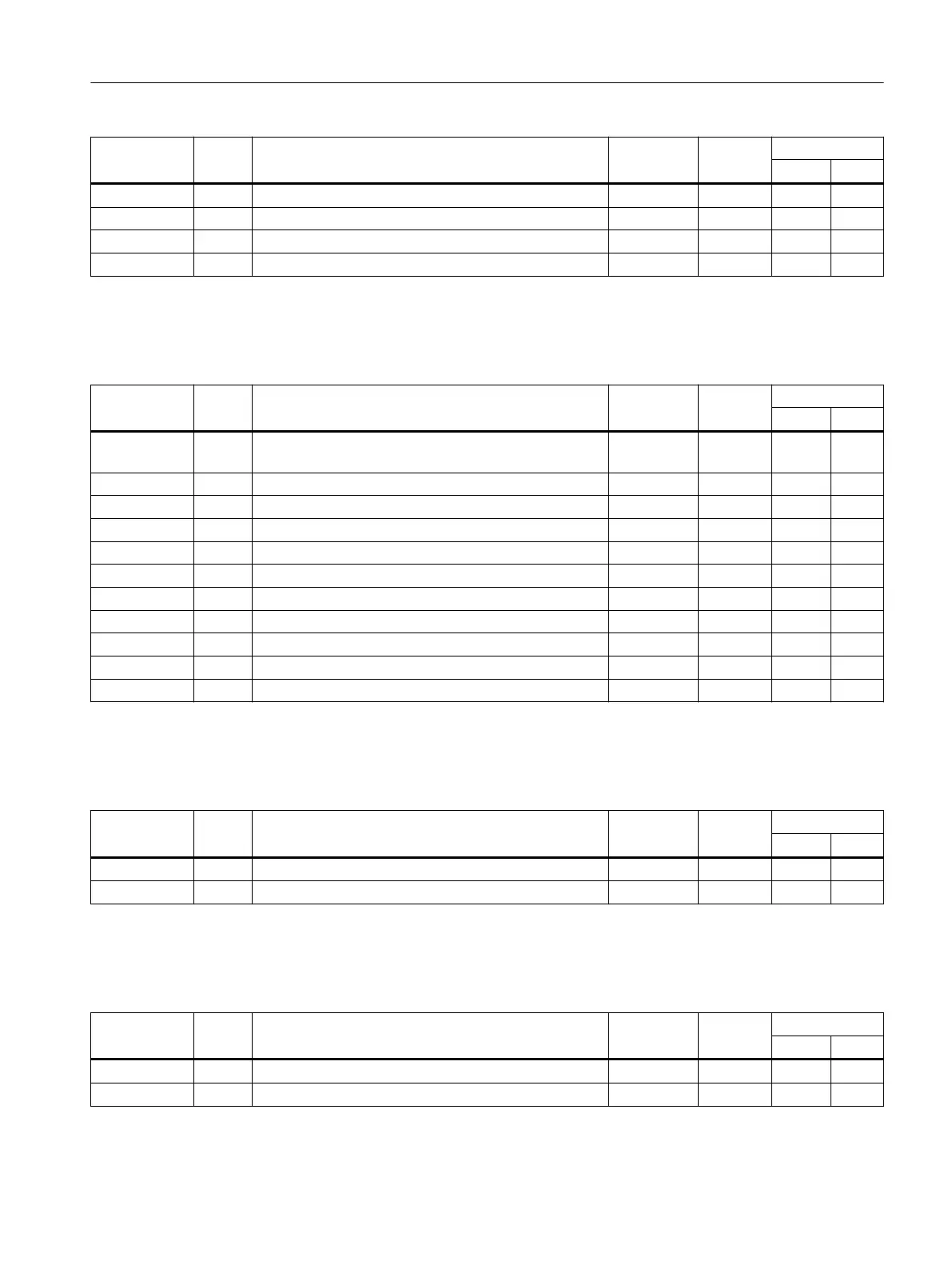

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

DYNROUGH 3 Roughing + m

DYNSEMIFIN 4 Rough finishing + m

DYNFINISH 5 Finishing + m

DYNPREC 6 Smooth finishing + m

4.3.59 G group 60: Working area limitation

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

WALCS0 1 Workpiece coordinate system working area limitation

OFF

+ m x

WALCS1 2 WCS working area limitation group 1 active + m

WALCS2 3 WCS working area limitation group 2 active + m

WALCS3 4 WCS working area limitation group 3 active + m

WALCS4 5 WCS working area limitation group 4 active + m

WALCS5 6 WCS working area limitation group 5 active + m

WALCS6 7 WCS working area limitation group 6 active + m

WALCS7 8 WCS working area limitation group 7 active + m

WALCS8 9 WCS working area limitation group 8 active + m

WALCS9 10 WCS working area limitation group 9 active + m

WALCS10 11 WCS working area limitation group 10 active + m

4.3.60 G group 61: Tool orientation smoothing

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

ORISOF 1 Tool orientation smoothing OFF + m x

ORISON 2 Tool orientation smoothing ON + m

4.3.61 G group 62: Repositioning mode for REPOS (non-modal)

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

RMBBL 1 Repositioning to start of block - s

RMIBL 2 Repositioning to interrupt point - s x

Tables

4.3 G commands

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1265

Loading...

Loading...