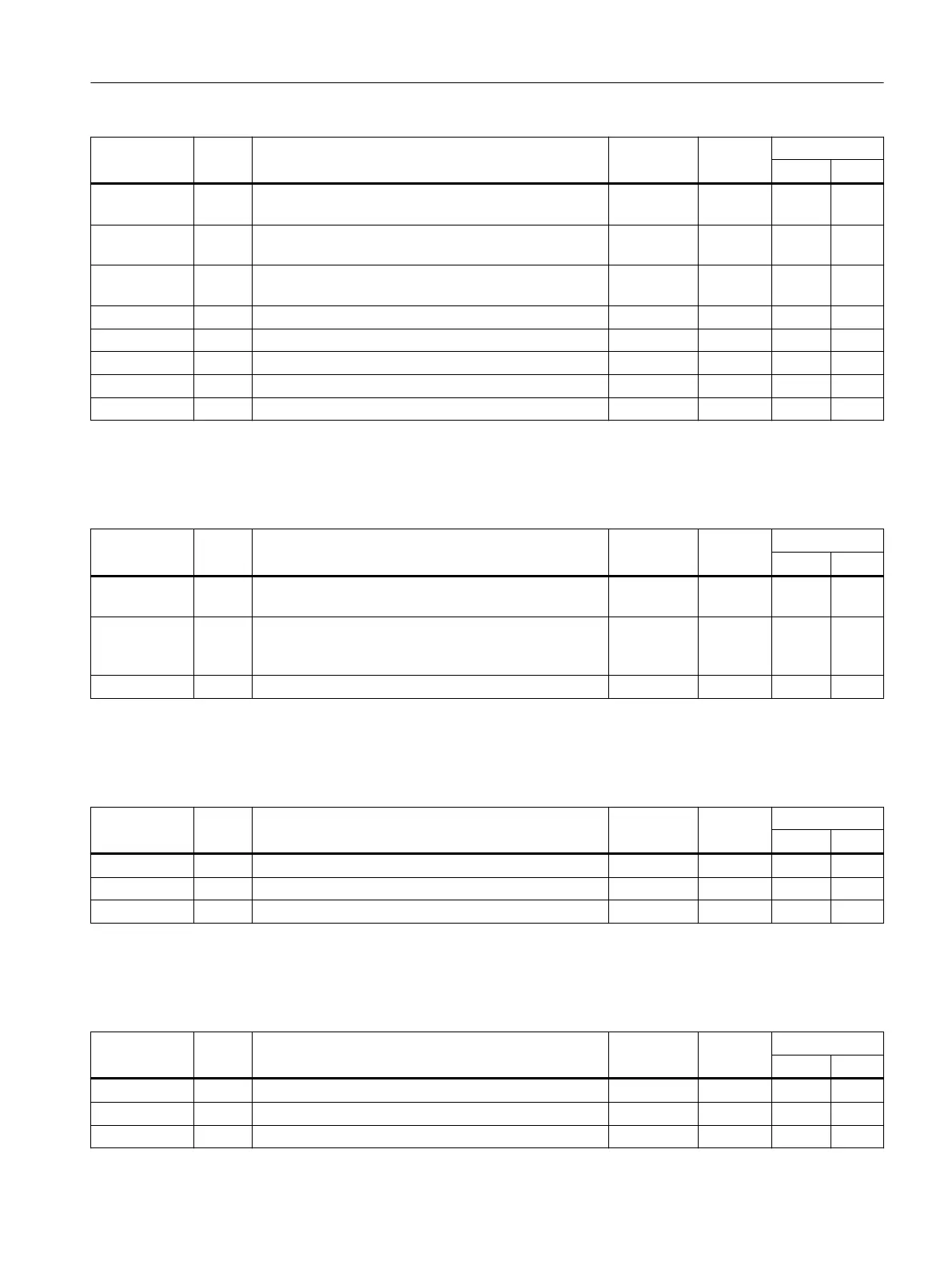

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

G26 11 Maximum working area limitation/spindle speed limita‐

tion

- s

G110 12 Pole programming relative to the last programmed set‐

point position

- s

G111 13 Polar programming relative to origin of current work‐

piece coordinate system

- s

G112 14 Pole programming relative to the last valid pole - s

G58 15 Absolute programmable work offset - s

G59 16 Additive programmable work offset - s

ROTS 17 Rotation with solid angle - s

AROTS 18 Additive rotation with solid angle - s

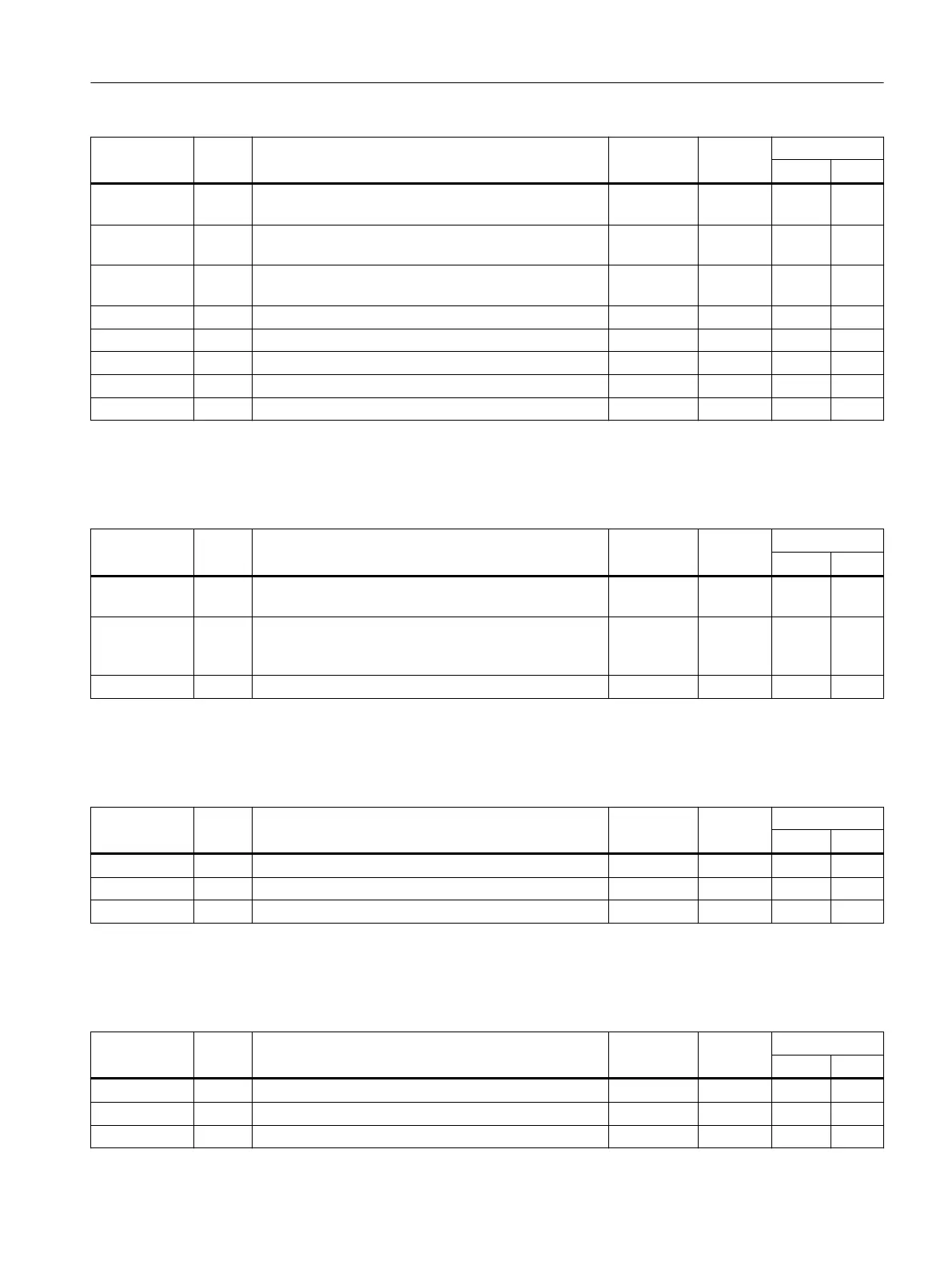

4.3.5 G group 4: FIFO

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

STARTFIFO 1 Start FIFO

Execute and simultaneously fill preprocessing memory

+ m x

STOPFIFO 2 STOP FIFO

Stop machining; fill preprocessing memory until

STARTFIFO is detected, FIFO is full or end of program

+ m

FIFOCTRL 3 Activation of automatic preprocessing memory control + m

4.3.6 G group 6: Plane selection

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

G17 1 Plane selection 1. – 2. Geometry axis + m x

G18 2 Plane selection 3. – 1. Geometry axis + m

G19 3 Plane selection 2. – 3. Geometry axis + m

4.3.7 G group 7: Tool radius compensation

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

G40 1 No tool radius compensation + m x

G41 2 Tool radius compensation left of the contour - m

G42 3 Tool radius compensation right of the contour - m

Tables

4.3 G commands

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1249

Loading...

Loading...