Activating intermediate block generation

If TLIFT(...) is programmed after TANG(...), an intermediate block automatically generated by

the control is inserted at this point when a corner is detected during preprocessing.

When the program is executed, the leading axes are stopped when the intermediate block is

reached. In the intermediate block, the following axis is rotated with maximum axis dynamics

toward the path tangent of the following block. The leading axes are then traversed further on

the programmed path.

Deactivating intermediate block generation

To deactivate intermediate block generation, the tangential coupling must be defined again

using TANG(...), but without subsequent activation of intermediate block generation by means

of TLIFT(...).

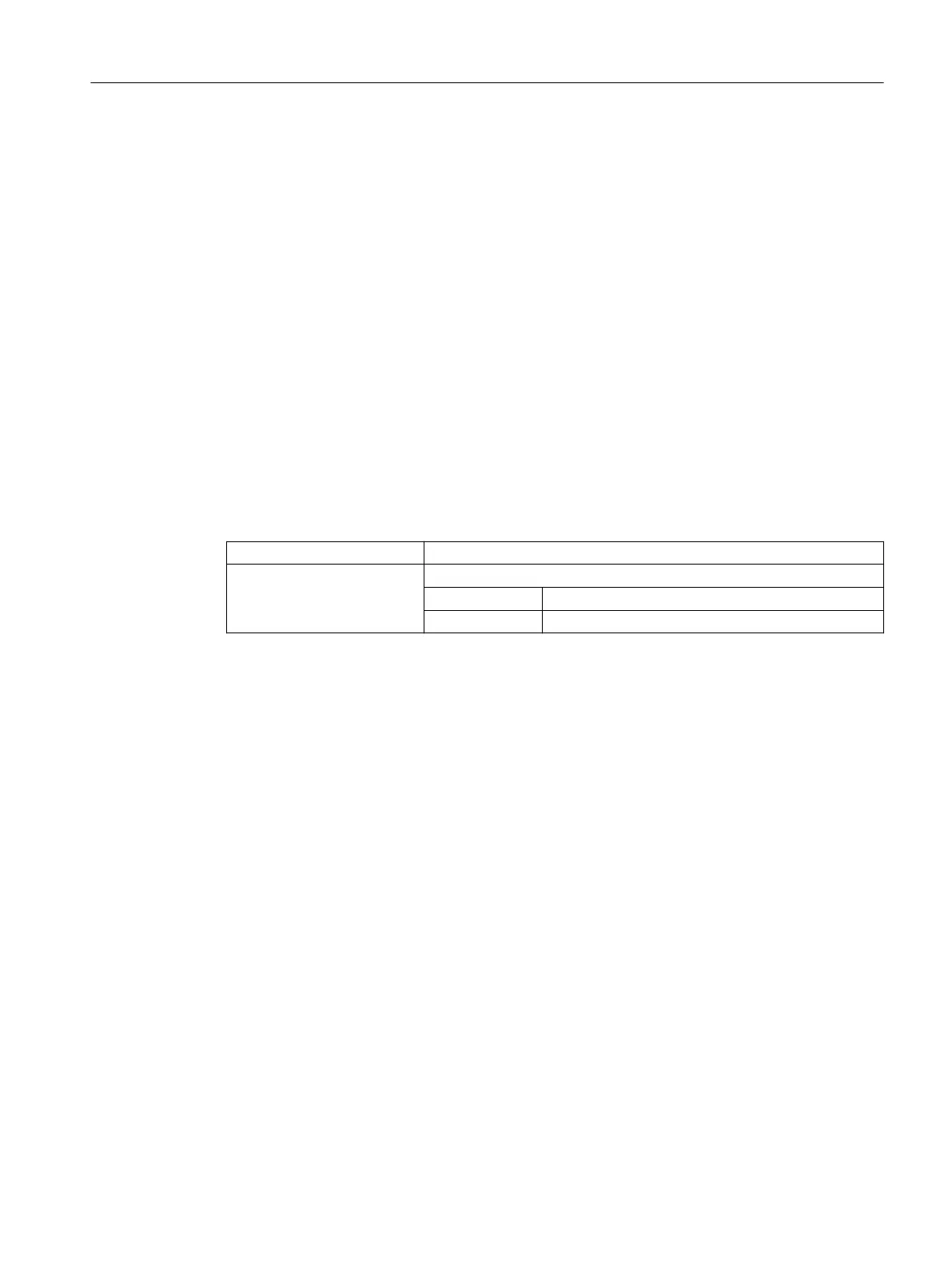

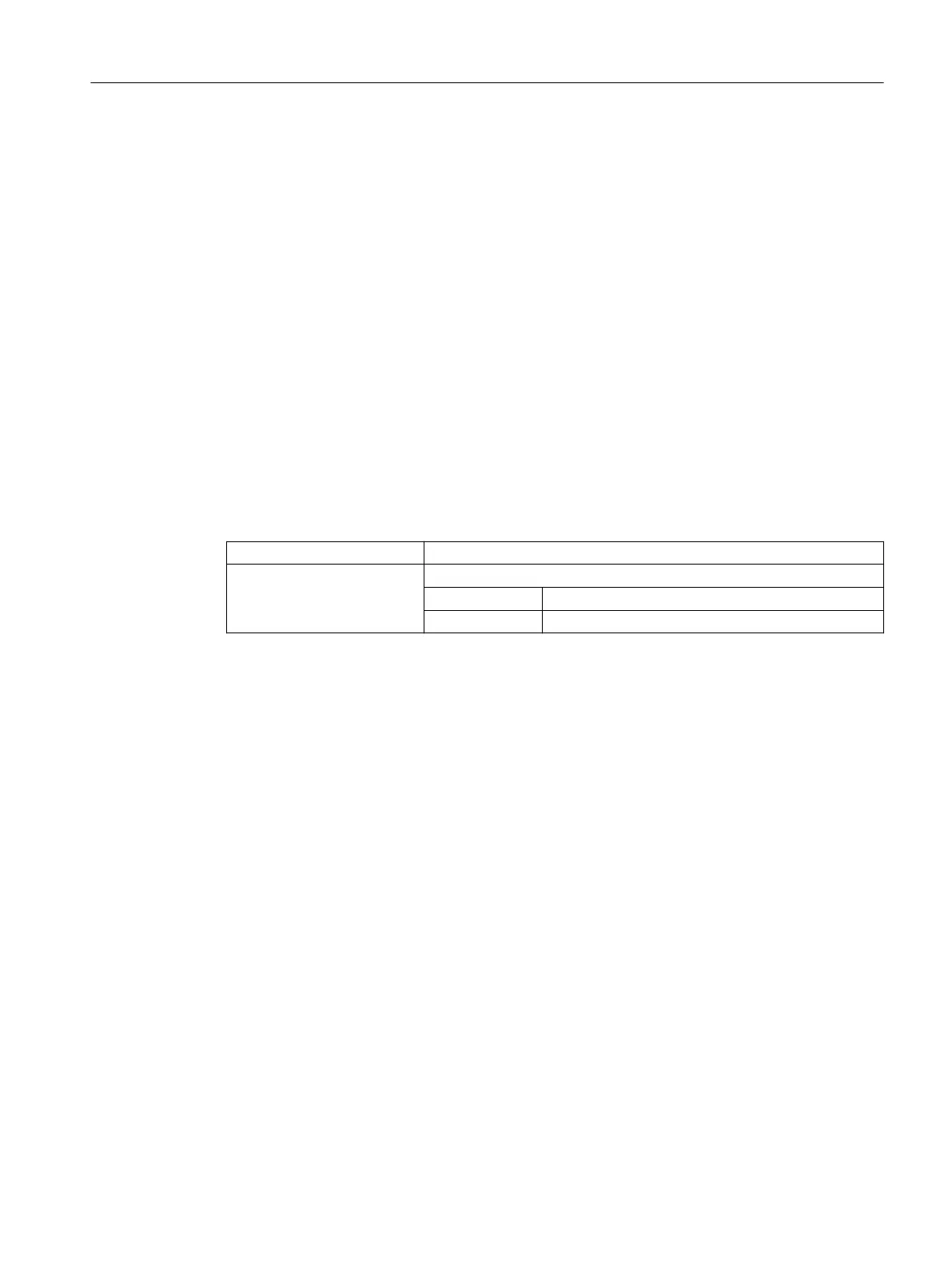

Syntax

TLIFT(<following axis>)

Meaning

TLIFT(...): Activate corner detection with intermediate block calculation

<following axis>: Axis name of the following axis (rotary axis)

Data type: AXIS

Range of values: Channel axis names

Speed of rotation of the following axis

Path axis

If the following axis had already been traversed as a path axis before tangential coupling was

activated, the rotational movement is performed in the intermediate block as a path axis.

If you specify the reference radius with FGREF[<axis>]=0.001, the rotational movement will

be performed with the parameterized maximum axis velocity:

MD32000 $MA_MAX_AX_VELO[<following axis>]

Positioning axis

If the following axis had not yet been traversed as a path axis before tangential coupling was

activated, the rotation is performed in the intermediate block as a positioning axis.

The rotational movement is performed with the parameterized positioning axis velocity:

MD32060 $MA_POS_AX_VELO[<following axis>]

3.16.7.3 Activating the coupling (TANGON)

Via the predefined procedure TANGON(...), a tangential coupling previously defined

with TANG(...) (Page 940) is activated. The following axis is then continuously aligned with the

path tangent during subsequent travel.

Work preparation

3.16 Axis couplings

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 943

Loading...

Loading...