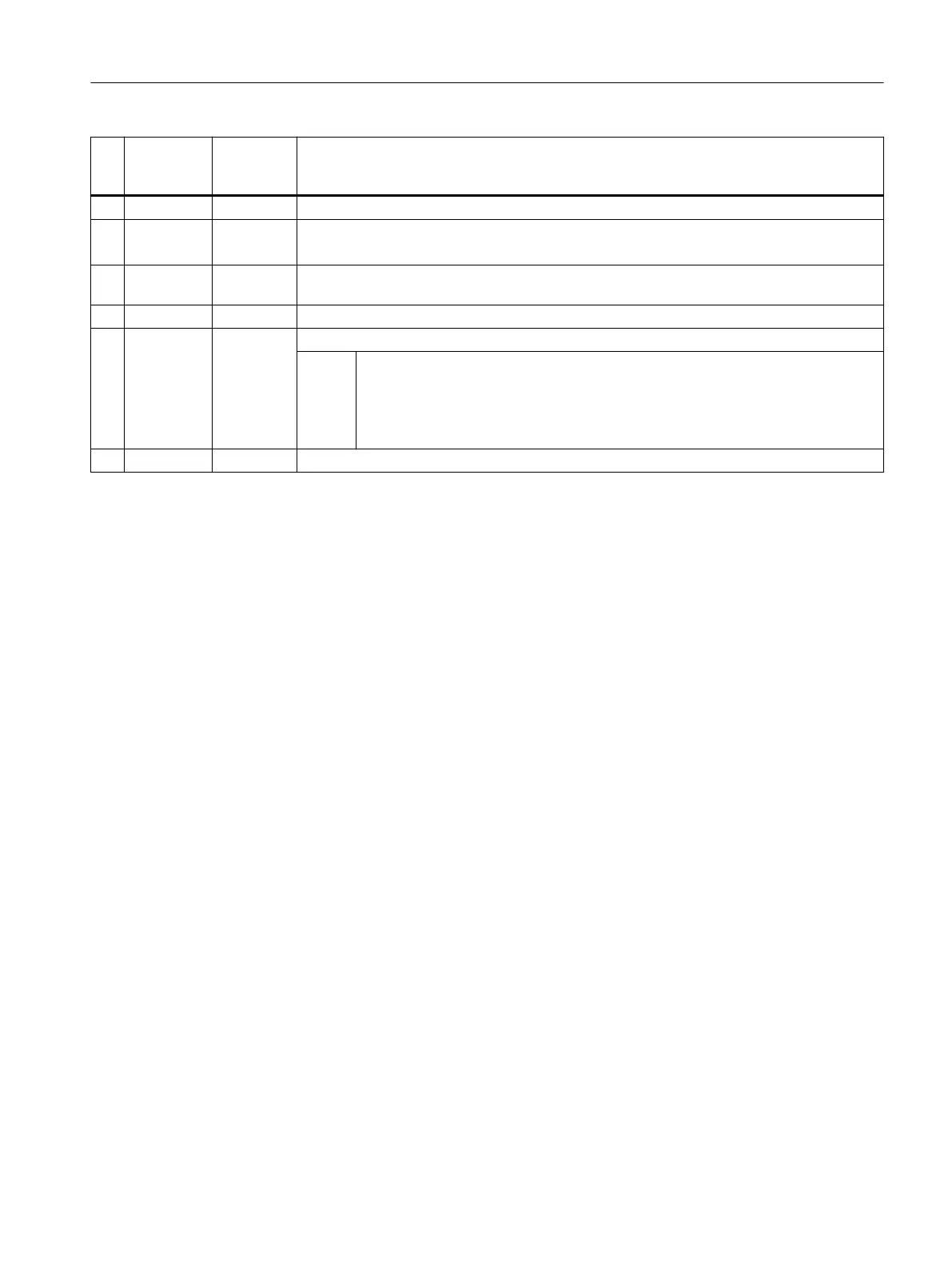

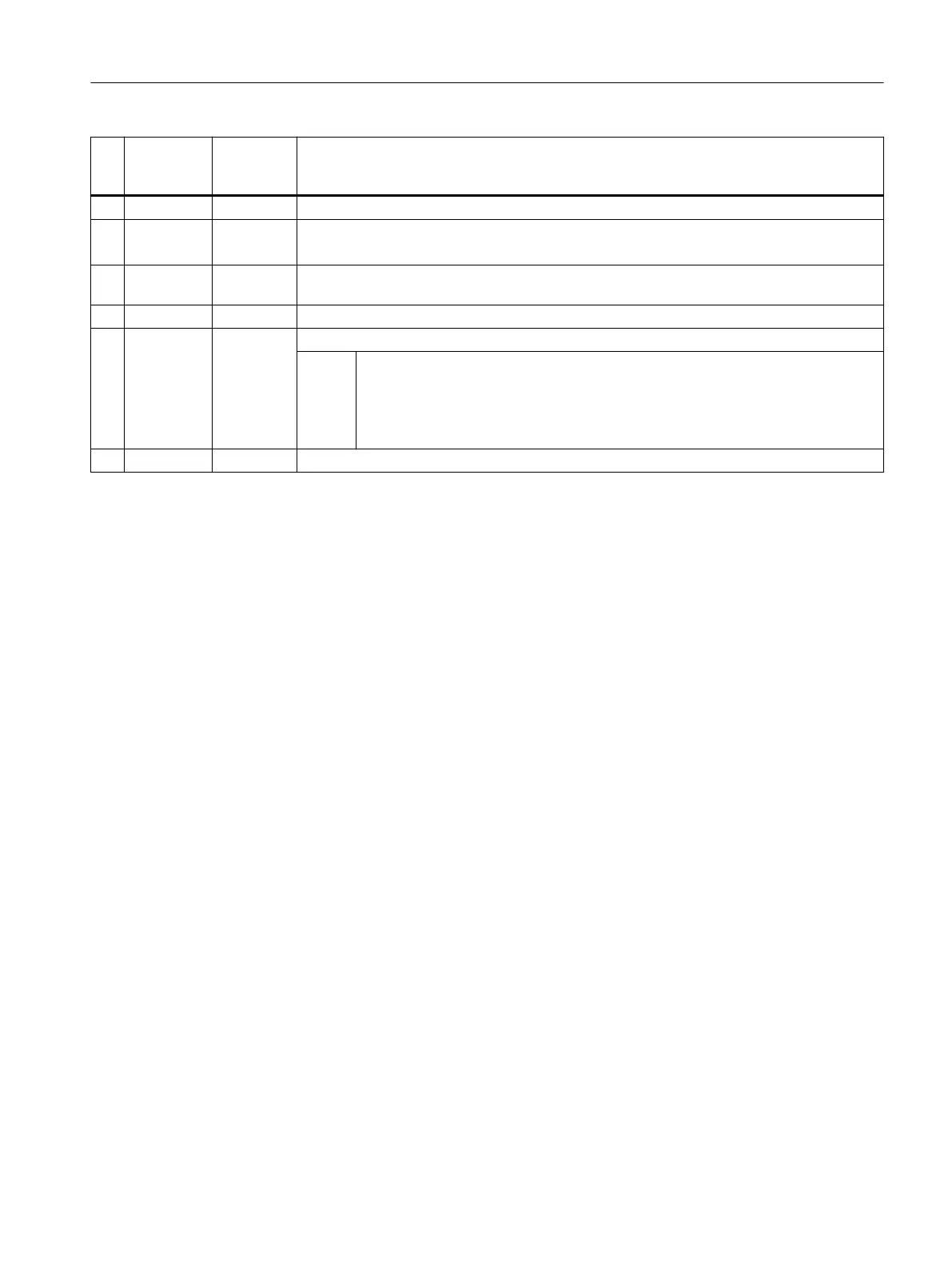

No

.

Screen

form pa‐

rameter

Cycle pa‐

rameter

Meaning

17 DFA S_FA Measurement path

18 TSA S_TSA Safe area

Monitoring the angular difference to the angle setpoint [degrees]

19 Measure‐

ments

S_NMSP Number of measurements at the same location

2)

(value range 1 to 9)

2)

20 S_MCBIT Reserved

21 _DMODE Display mode

Val‐

ues:

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane active before the cycle call remains active

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

22 _AMODE Alternative mode

1)

All default values = 0 or marked as the range of values a to b

2)

Display depends on the general SD54760 $SNS_MEA_FUNCTION_MASK_PIECE

3)

Input of the measuring points in polar coordinates, taking into account the starting angle S_STA1 for measuring point 3 or

4 of the incremental angle S_INCA.

4)

Input of the measuring points in the right-angled coordinate system (input using 4 points)

5)

If WO "fine" has not been set up in MDs, correction is according to WO "coarse".

6)

Value range of angle S_INCA: -180 to +180 degrees

7)

Starting angle S_STA1, value range: right-angled corner: +- 90 degrees, any corner: +- 45 degrees

3.25.3.9 CYCLE979 measuring cycle parameters

PROC CYCLE979(INT S_MVAR,INT S_KNUM,INT S_KNUM1,INT S_PRNUM,REAL S_SETV,REAL S_FA,REAL

S_TSA,REAL S_CPA,REAL S_CPO,REAL S_STA1,REAL S_INCA,INT S_NMSP,STRING[32] S_TNAME,REAL

S_DLNUM,REAL S_TZL,REAL S_TDIF,REAL S_TUL,REAL S_TLL,REAL S_TMV,INT S_K,INT S_EVNUM,INT

S_MCBIT,INT _DMODE,INT _AMODE,REAL S_XM,REAL S_YM,INT _DP)

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1177

Loading...

Loading...