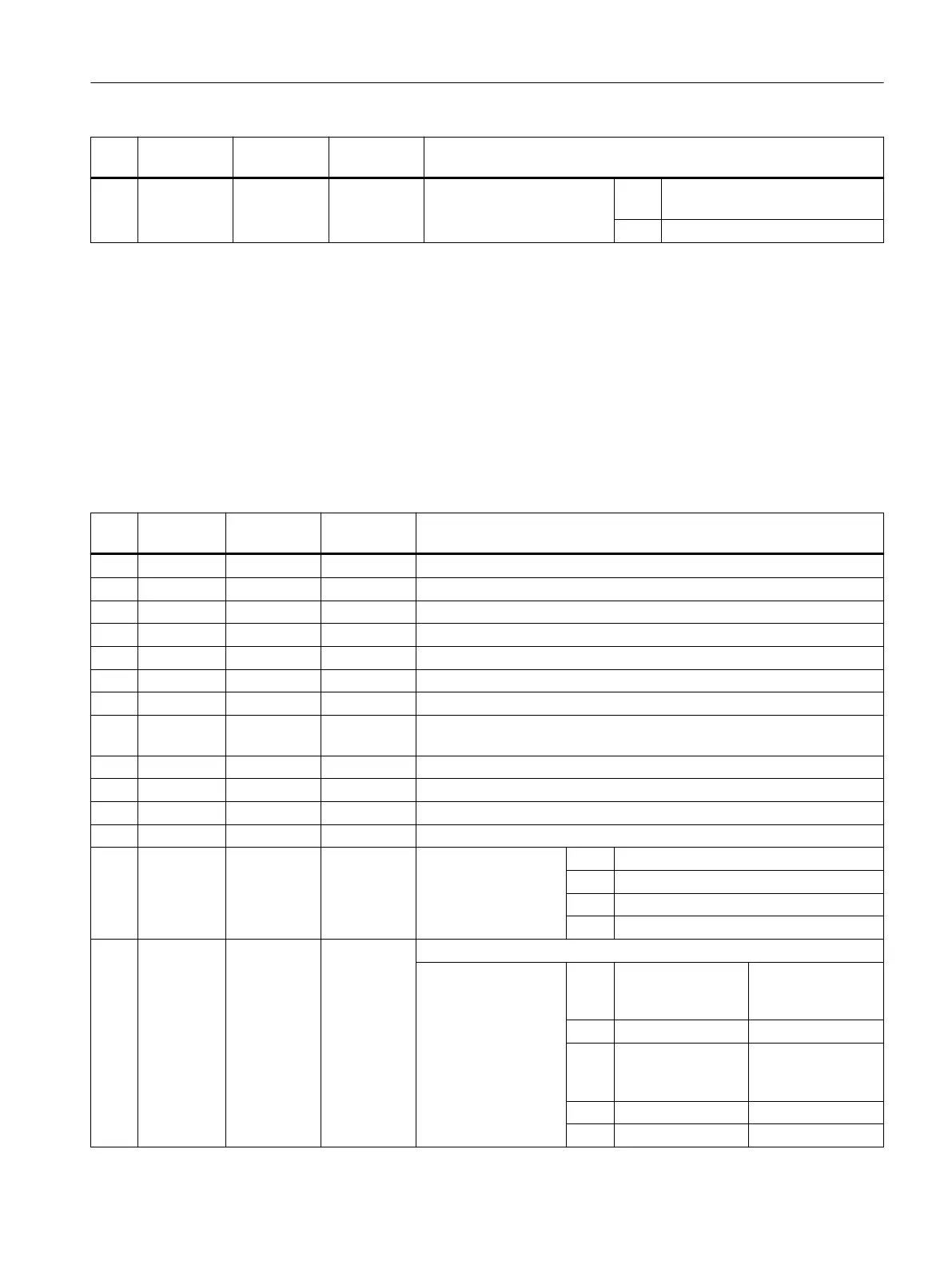

No. Parameter

mask

Parameter

internal

Data type Meaning

0 = Compatibility, as a factor (0.001

to 1.0, FRF = 0 means 100%)

1 = Percentage (0.001 to 999.999%)

3.25.1.24 CYCLE84 - tapping without compensating chuck

Syntax

CYCLE84(<RTP>, <RFP>, <SDIS>, <DP>, <DPR>, <DTB>, <SDAC>, <MPIT>,

<PIT>, <POSS>, <SST>, <SST1>, <_AXN>, <_PITA>, <_TECHNO>, <_VARI>,

<_DAM>, <_VRT>, <_PITM>, <_PTAB>, <_PTABA>, <_GMODE>, <_DMODE>,

<_AMODE>)

Parameters

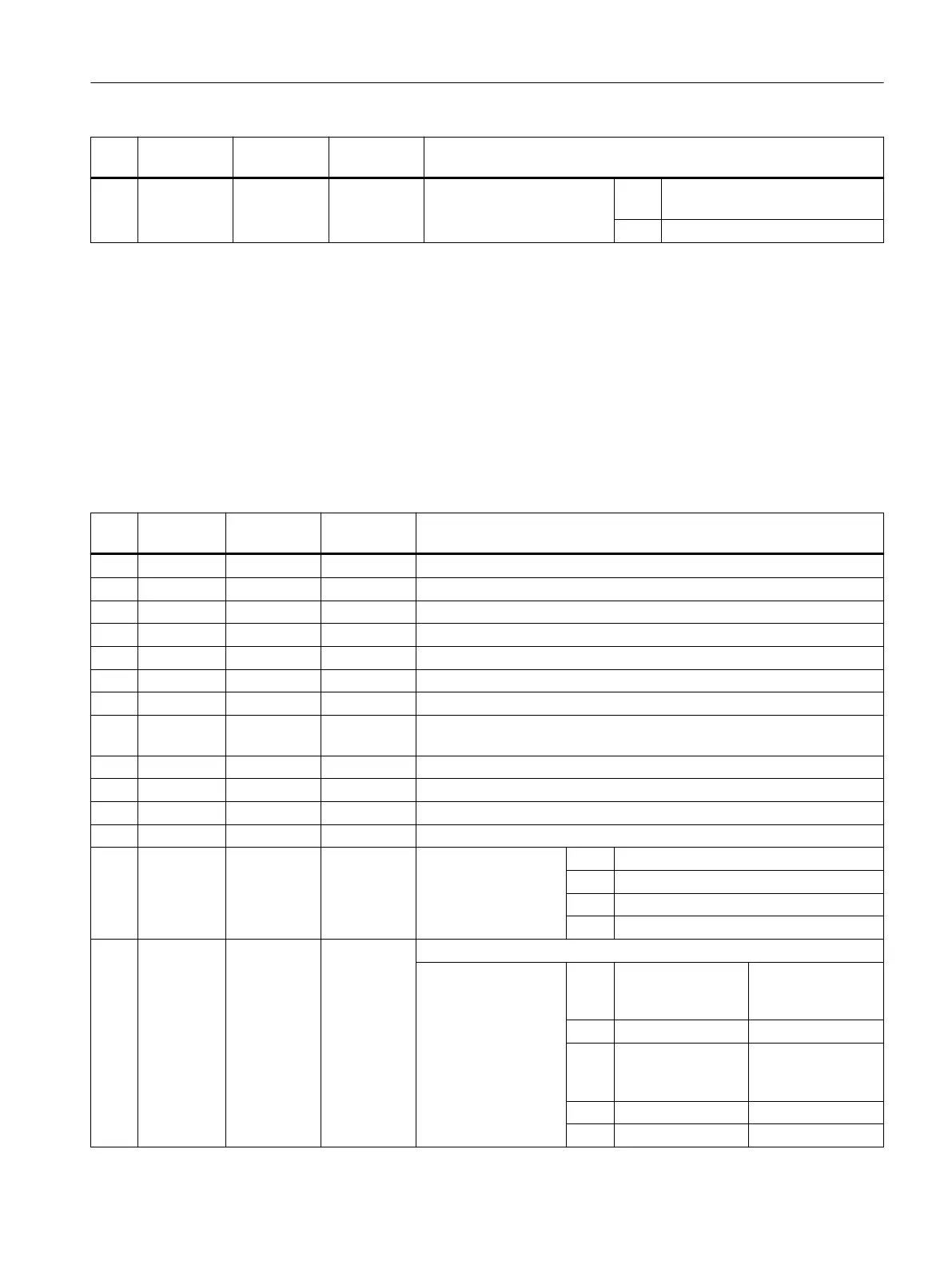

No. Parameter

mask

Parameter

internal

Data type Meaning

1 RP <RTP> REAL Retraction plane (abs)

2 Z0 <RFP> REAL Reference point (abs)

3 SC <SDIS> REAL Safety clearance (to be added to reference point, enter without sign)

4 Z1 <DP> REAL Drilling depth = final drilling depth (abs), see <_AMODE>

5 Z1 <DPR> REAL Drilling depth = final drilling depth (inc), see <_AMODE>

6 DT <DTB> REAL Dwell time at drilling depth in seconds

7 SDE <SDAC> INT Direction of rotation after end of cycle

8 <MPIT> REAL Thread size for "ISO metric" only (pitch is calculated internally during run

time)

9 P <PIT> REAL Pitch as a value, for unit see <_PITA>

10 αS

1)

<POSS> REAL Spindle position for oriented spindle stop

11 S <SST> REAL Spindle speed for tapping

12 SR <SST1> REAL Spindle speed for retraction

13 <_AXN> INT Drilling axis 0 = 3rd geometry axis

1 = 1st geometry axis

2 = 2nd geometry axis

≥ 3 = 3rd geometry axis

14 <_PITA> INT Pitch unit (evaluation of <PIT> and <MPIT>)

0 = Pitch in mm - evalua‐

tion<MPIT>/

<PIT>

1 = Pitch in mm - evaluation<PIT>

2 = Pitch in TPI - evaluation of

<PIT>

(threads per inch)

3 = Pitch in inches - evaluation<PIT>

4 = MODULUS - evaluation<PIT>

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1071

Loading...

Loading...