Taper thread with increasing pitch:

G34 X… Z… K… F...

G34 X… Z… I… F...

Taper thread with decreasing pitch:

G35 X… Z… K… F...

G35 X… Z… I… F...

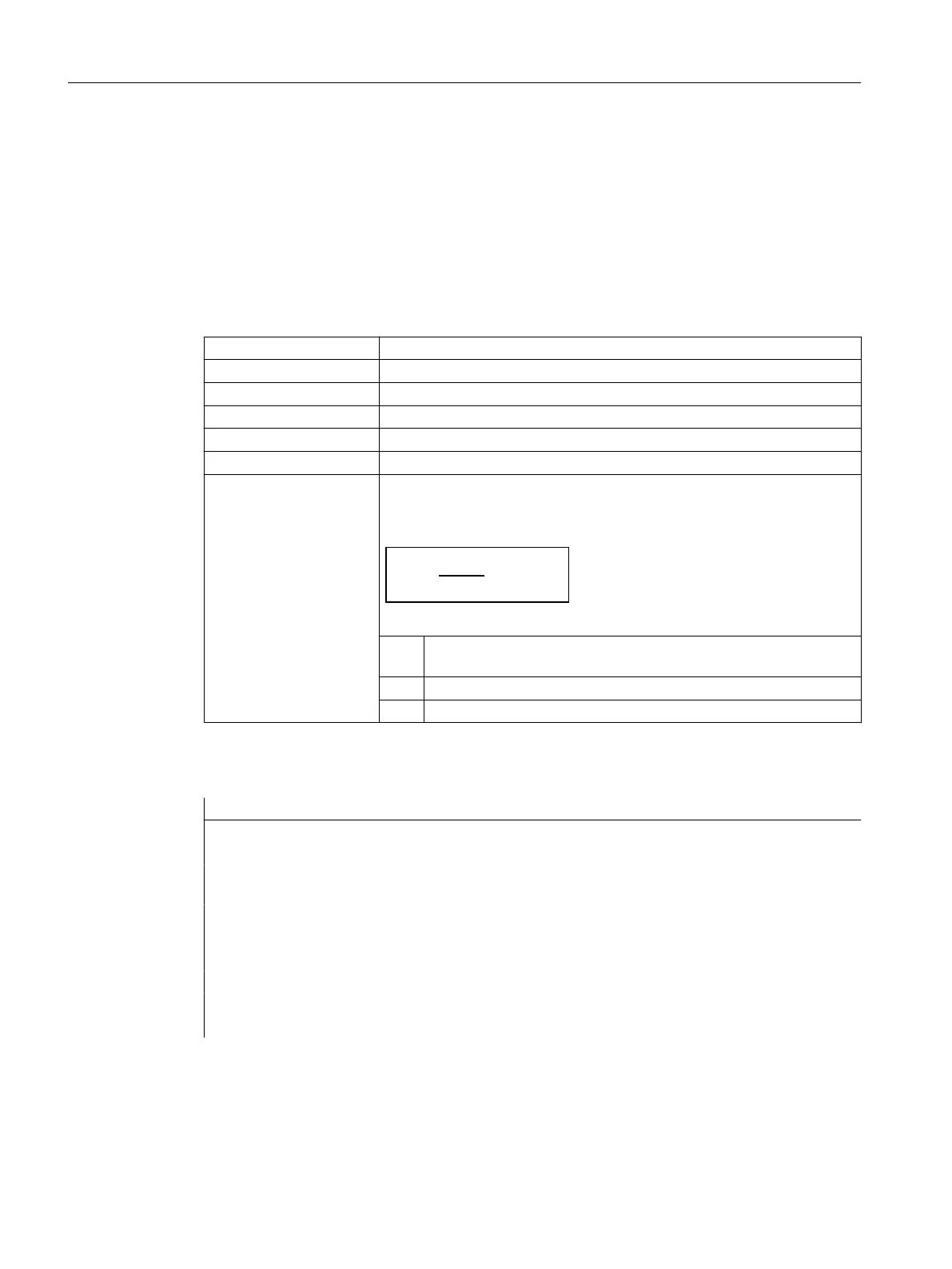

Meaning

G34: Command for thread cutting with linear increasing pitch

G35: Command for thread cutting with linear decreasing pitch

X... Y... Z... : End point(s) in Cartesian coordinates

I... : Thread pitch in X direction

J... : Thread pitch in Y direction

K... : Thread pitch in Z direction

F... : Thread pitch change

If you already know the starting and final pitch of a thread, you can calculate

the thread pitch change to be programmed using the following equation:

N

H

N

D

)

,

*

>PPUHY

@

The meanings are as follows:

k

e

: Final pitch thread (thread pitch of axis target point coordinate) [mm/

rev]

k

a

: Starting thread pitch (programmed under I, J or K) [mm/rev]

I

G

: Thread length [mm]

Example

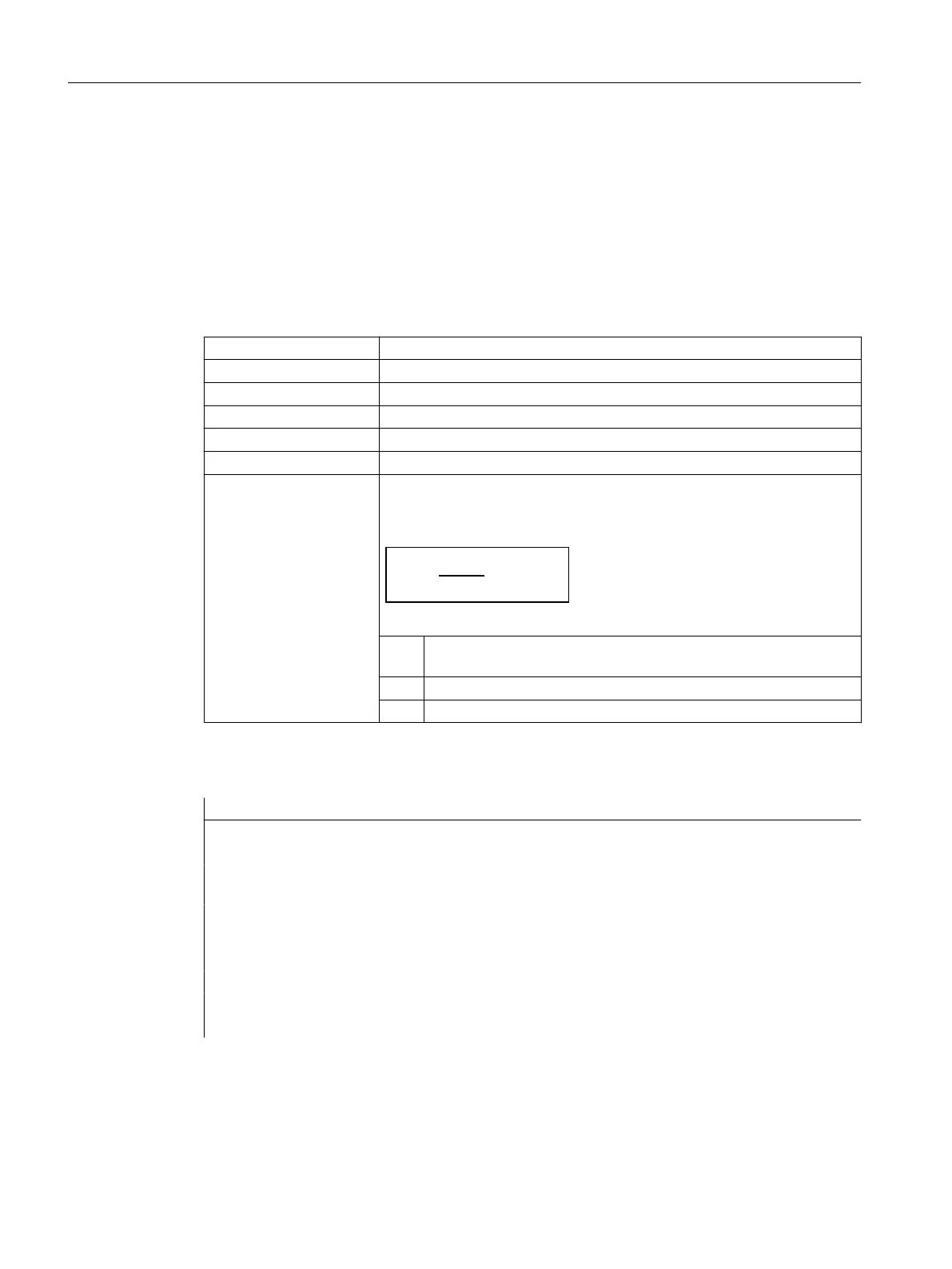

Program code Comment

N1608 M3 S10 ; Spindle on.

N1609 G0 G64 Z40 X216 ; Approach starting point.

N1610 G33 Z0 K100 SF=R14 ; Thread cutting with constant pitch

(100 mm/rev).

N1611 G35 Z-200 K100 F17.045455 ; Pitch decrease: 17.0454 mm/rev2

Pitch at end of block: 50 mm/rev

N1612 G33 Z-240 K50 ; Traverse thread block without jerk.

N1613 G0 X218

N1614 G0 Z40

N1615 M17

2.9.10.3 Programmed run-in and run-out path for G33, G34 and G35 (DITS, DITE)

The run-in and run-out path of the thread can be specified in the part program with the DITS

and DITE addresses.

Fundamentals

2.9 Motion commands

NC programming

228 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...