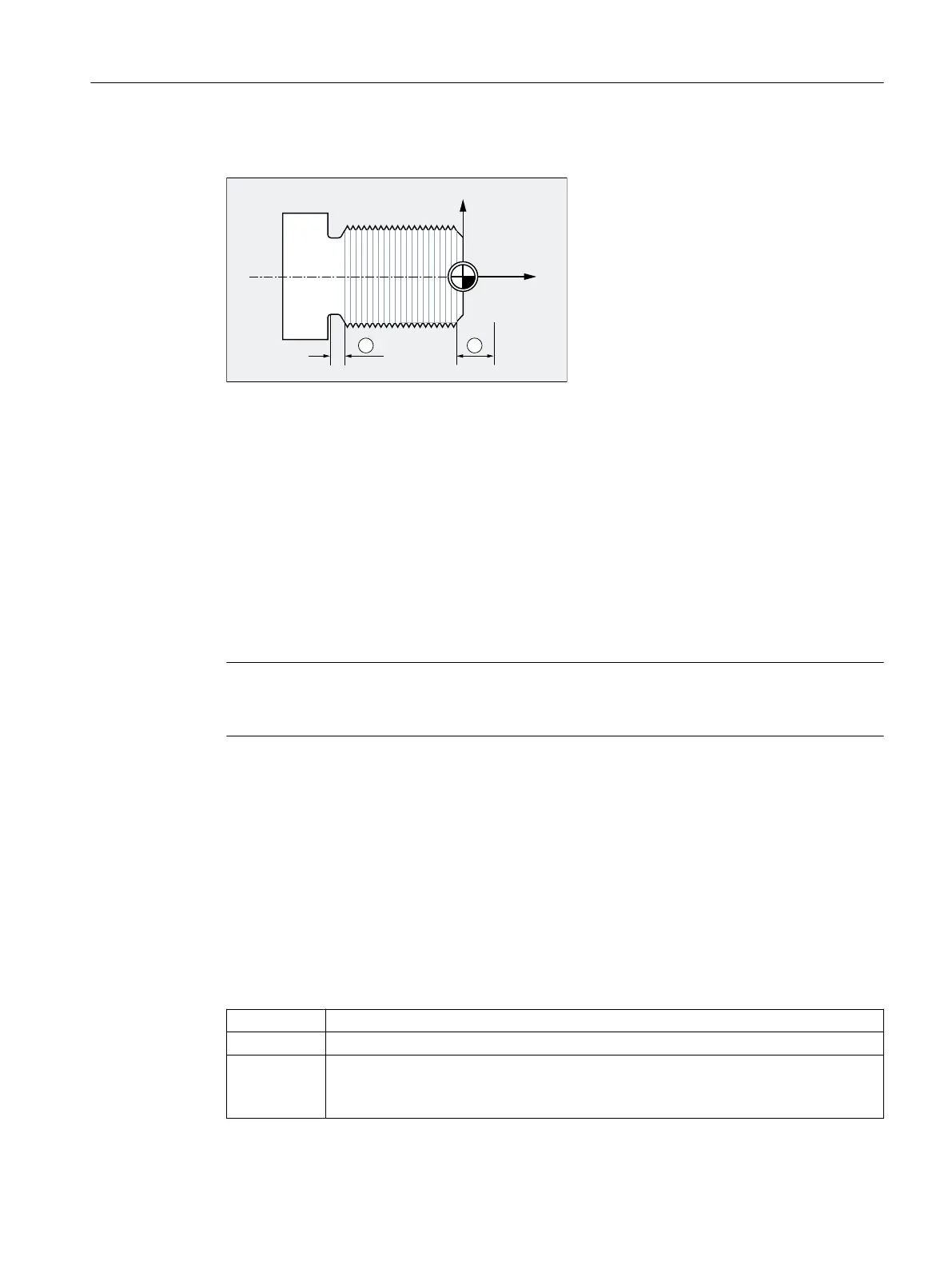

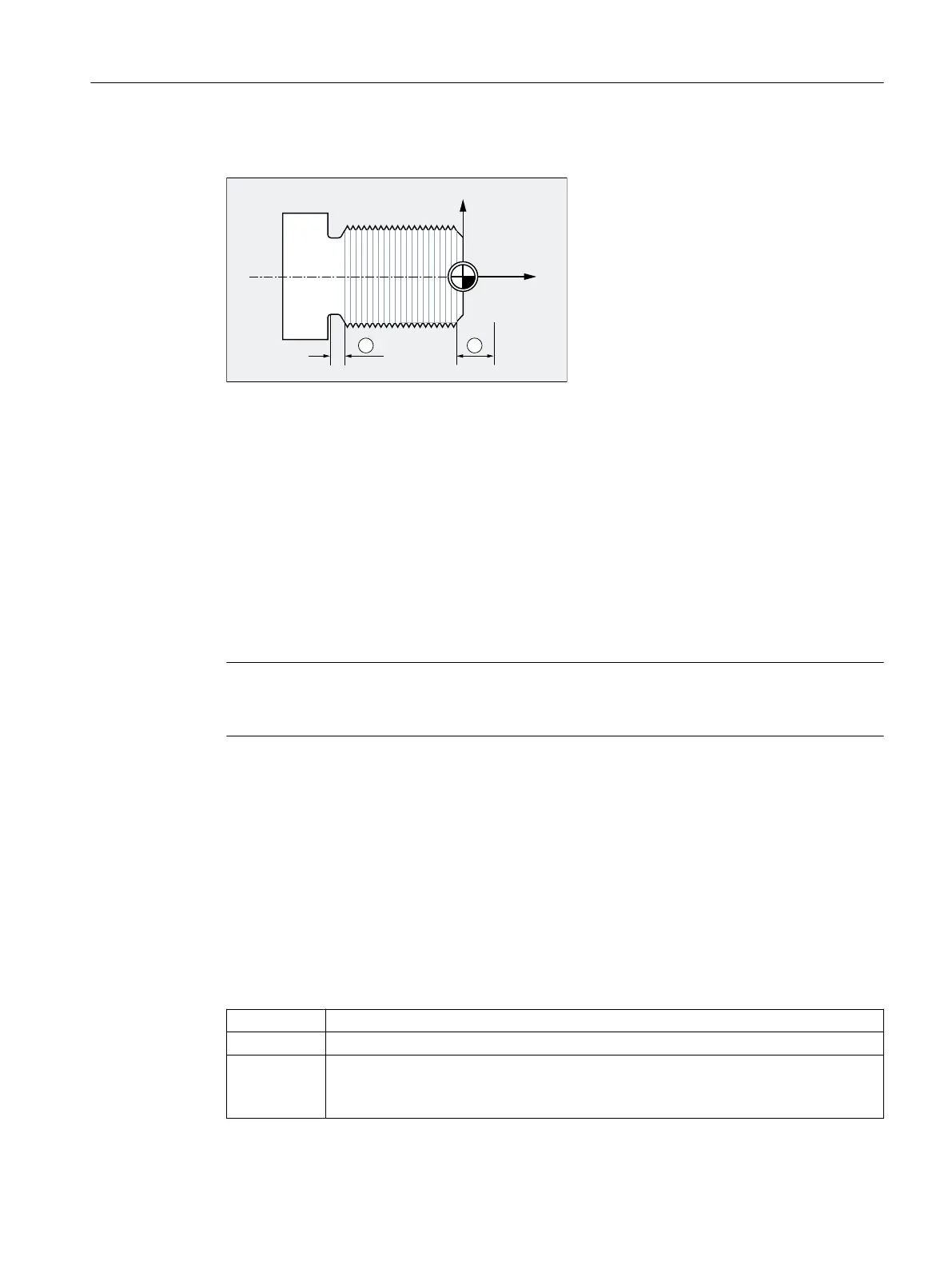

The thread axis is accelerated or braked along the specified path.

① Run-in/run-out path, depending on the machining direction

Short run-in path

Due to the collar on the thread runin, little room is left for the tool start ramp.

This must therefore be specified shorter via DITS.

Short run-out path

Because of the shoulder at the thread run-out, there is not much room for the tool braking ramp,

introducing a risk of collision between the workpiece and the tool cutting edge. The deceleration

ramp can be specified shorter using DITE. Due to the inertia of the mechanical system,

however, a collision can still occur.

Remedy: Program a shorter thread, reduce the spindle speed.

Note

DITE acts at the end of the thread as a rounding clearance. This achieves a smooth change in

the axis motion.

Effects

The programmed run-in and run-out path only increases the rate of acceleration on the path. If

one of the two paths is set larger than the thread axis needs with active acceleration, the thread

axis is accelerated or decelerated with maximum acceleration.

Syntax

DITS=<Value> DITE=<Value>

Meaning

DITS: Define thread run-in path

DITE: Define thread run-out path

<value>: Only paths, and not positions, are programmed with DITS and DITE.

The programmed run-in/run-out path is handled according to the current dimension

setting (inches, metric).

Fundamentals

2.9 Motion commands

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 229

Loading...

Loading...