3.13.3.1 Mirroring of tool lengths

When setting data SD42900 $SC_MIRROR_TOOL_LENGTH and

SD42910 $SC_MIRROR_TOOL_WEAR are not set to zero, then you can mirror the tool length

components and components of the basis dimensions with wear values and their associated

axes.

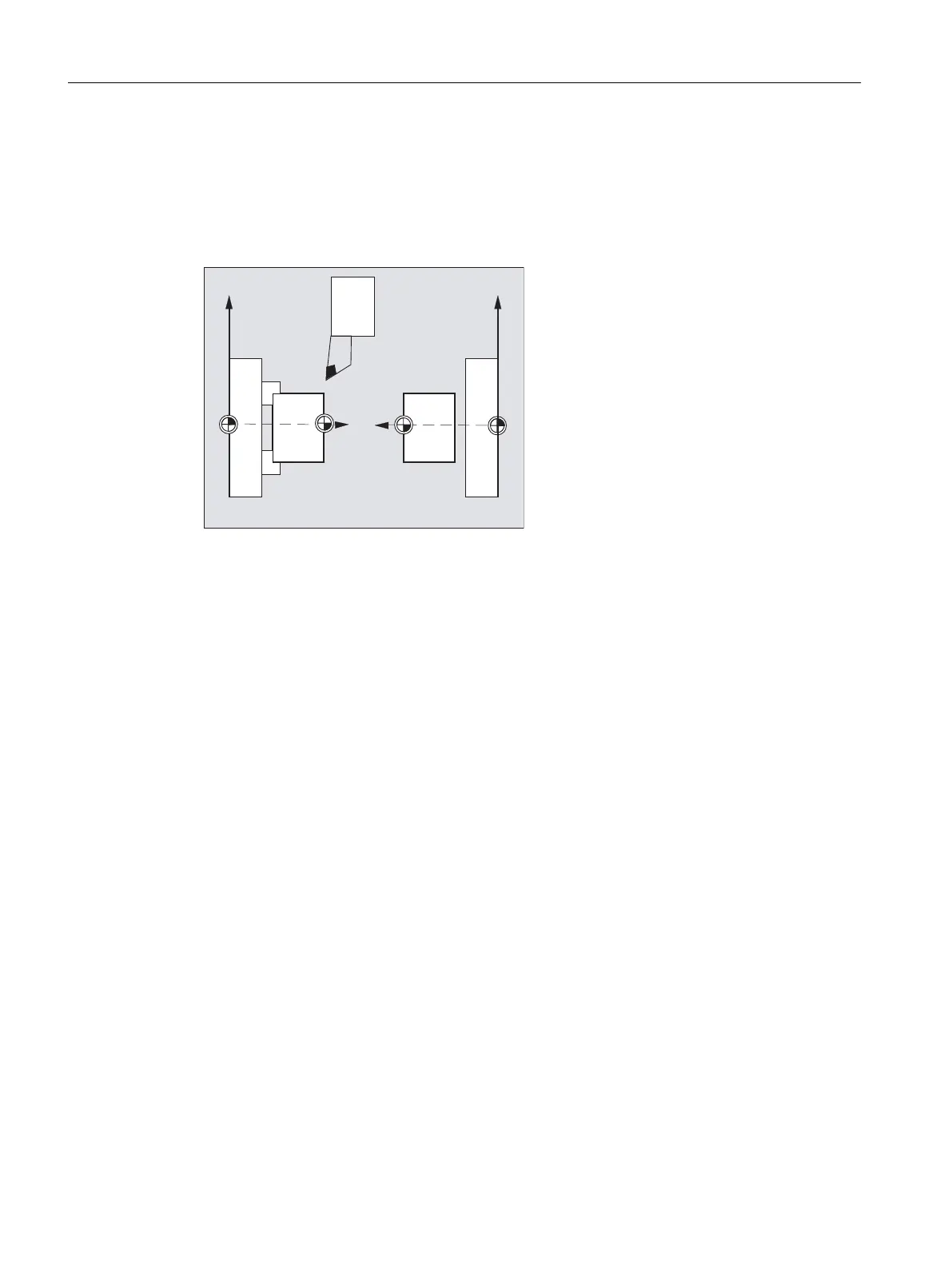

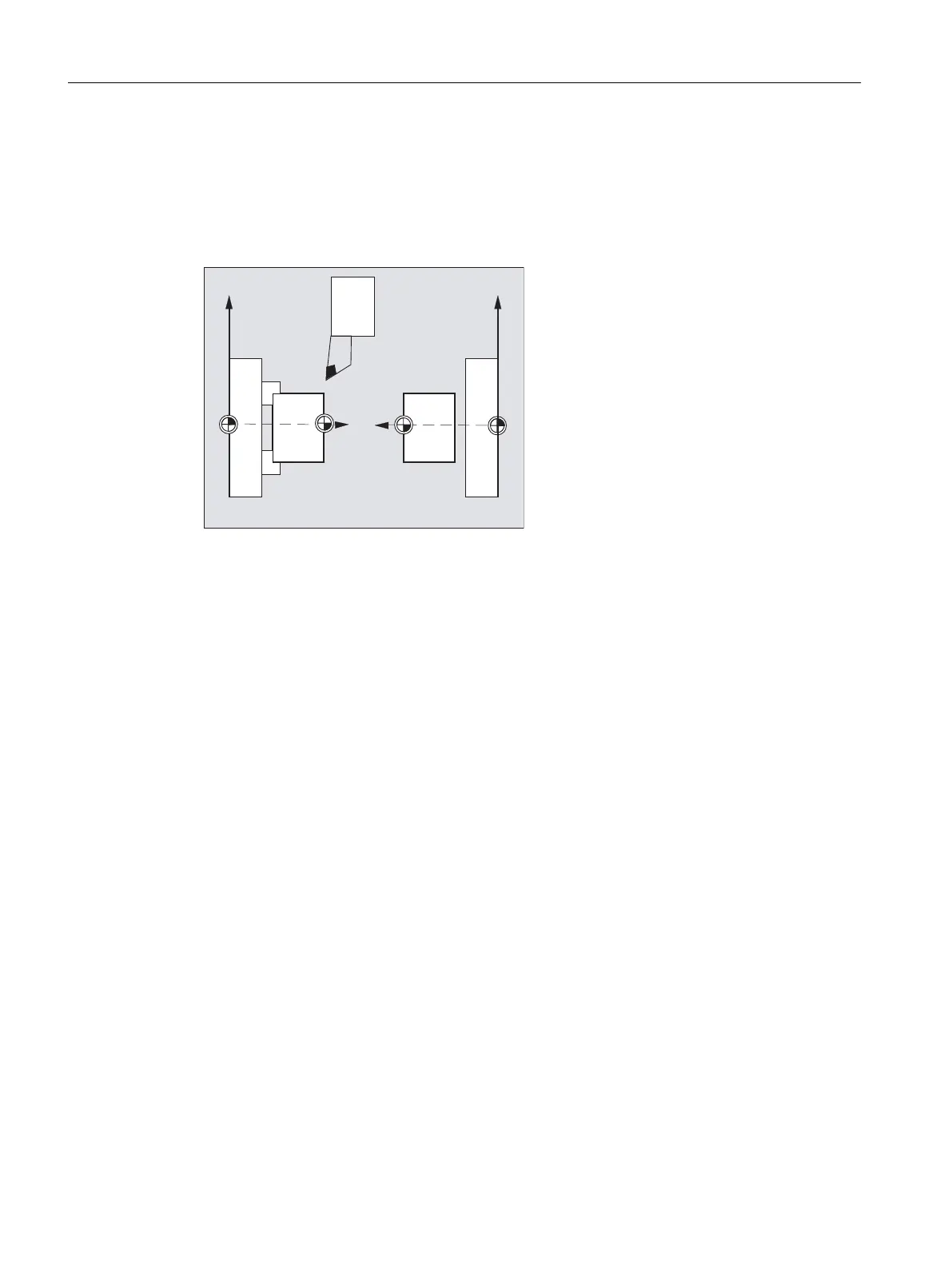

Z

W

Z

M

W

1

1

X

M

WCS 1

D13 with SL3

X

WCS 2

D13 with SL4

D13

SD42900 $SC_MIRROR_TOOL_LENGTH

Setting data not equal to zero:

The tool length components ($TC_DP3, $TC_DP4 and $TC_DP5) and the components of the

basis dimensions ($TC_DP21, $TC_DP22 and $TC_DP23) are mirrored against their

associated axes, also mirrored – by inverting the sign.

The wear values are not mirrored. If these are also be be mirrored, then setting data

SD42910 $SC_MIRROR_TOOL_WEAR must be set.

SD42910 $SC_MIRROR_TOOL_WEAR

Setting data not equal to zero:

The wear values of the tool length components - whose associated axes are mirrored - are also

mirrored by inverting the sign.

3.13.3.2 Wear sign evaluation

When setting data SD42920 $SC_WEAR_SIGN_CUTPOS and SD42930 $SC_WEAR_SIGN

are set not equal to zero, then you can invert the sign evaluation of the wear components.

SD42920 $SC_WEAR_SIGN_CUTPOS

Setting data not equal to zero:

For tools with the relevant cutting edge position (turning and grinding tools, tool types 400), then

the sign evaluation of the wear components in the machining plane depends on the cutting

edge position. This setting data is of no significance for tool types without relevant cutting edge

position.

Work preparation

3.13 Tool offsets

NC programming

746 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...