Note

If certain transfer parameters (e.g. <_VARI>, <_GMODE>, <_DMODE>, <_AMODE>) have

been indirectly programmed as parameters, the screen form is opened on recompiling but it

cannot be stored as there is no unambiguous assignment to defined selection fields.

3.25.1.2 Technology-specific overview

The following overview table lists all available externally programmable technology cycles and

the technology assigned to each of them:

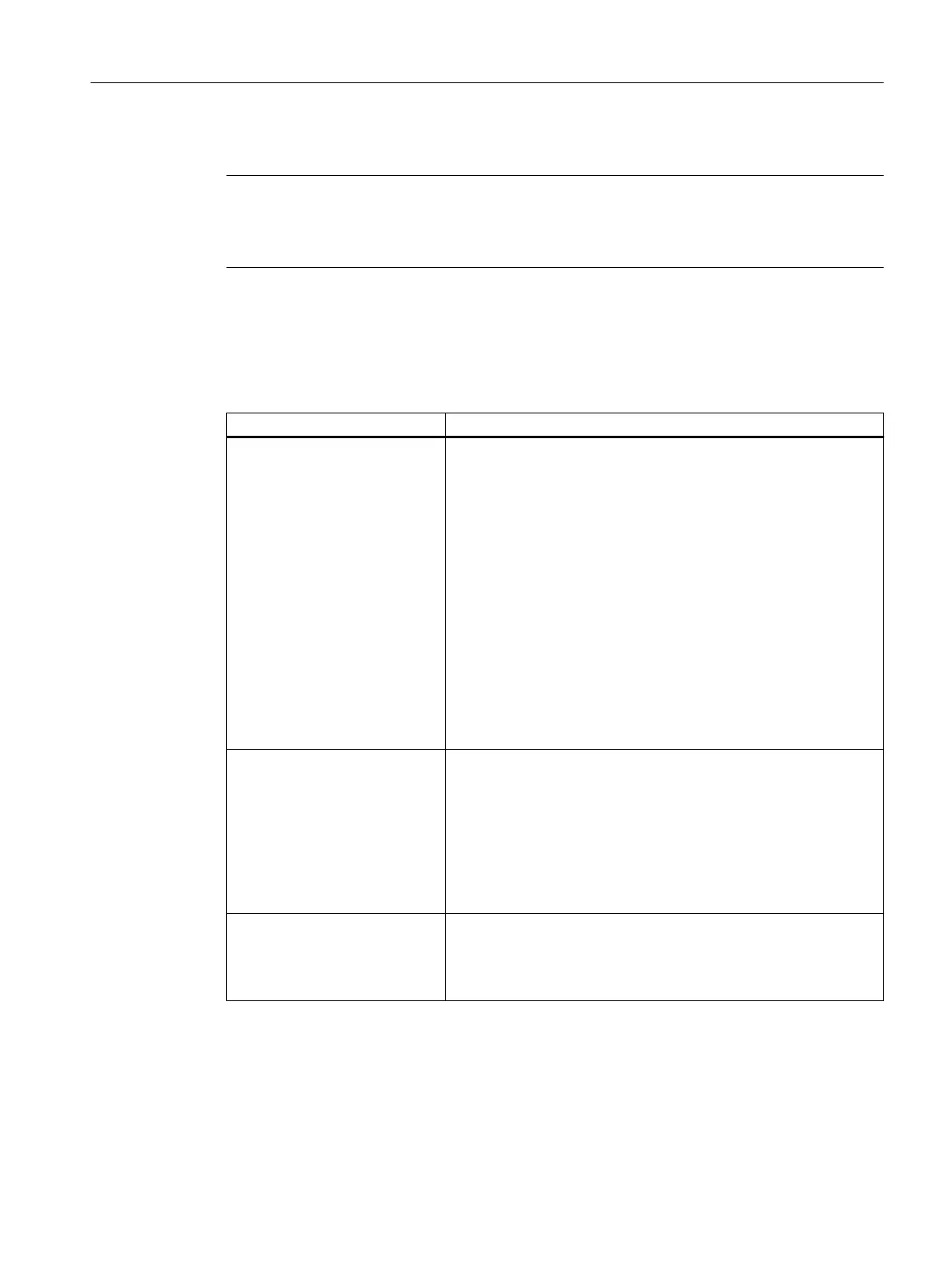

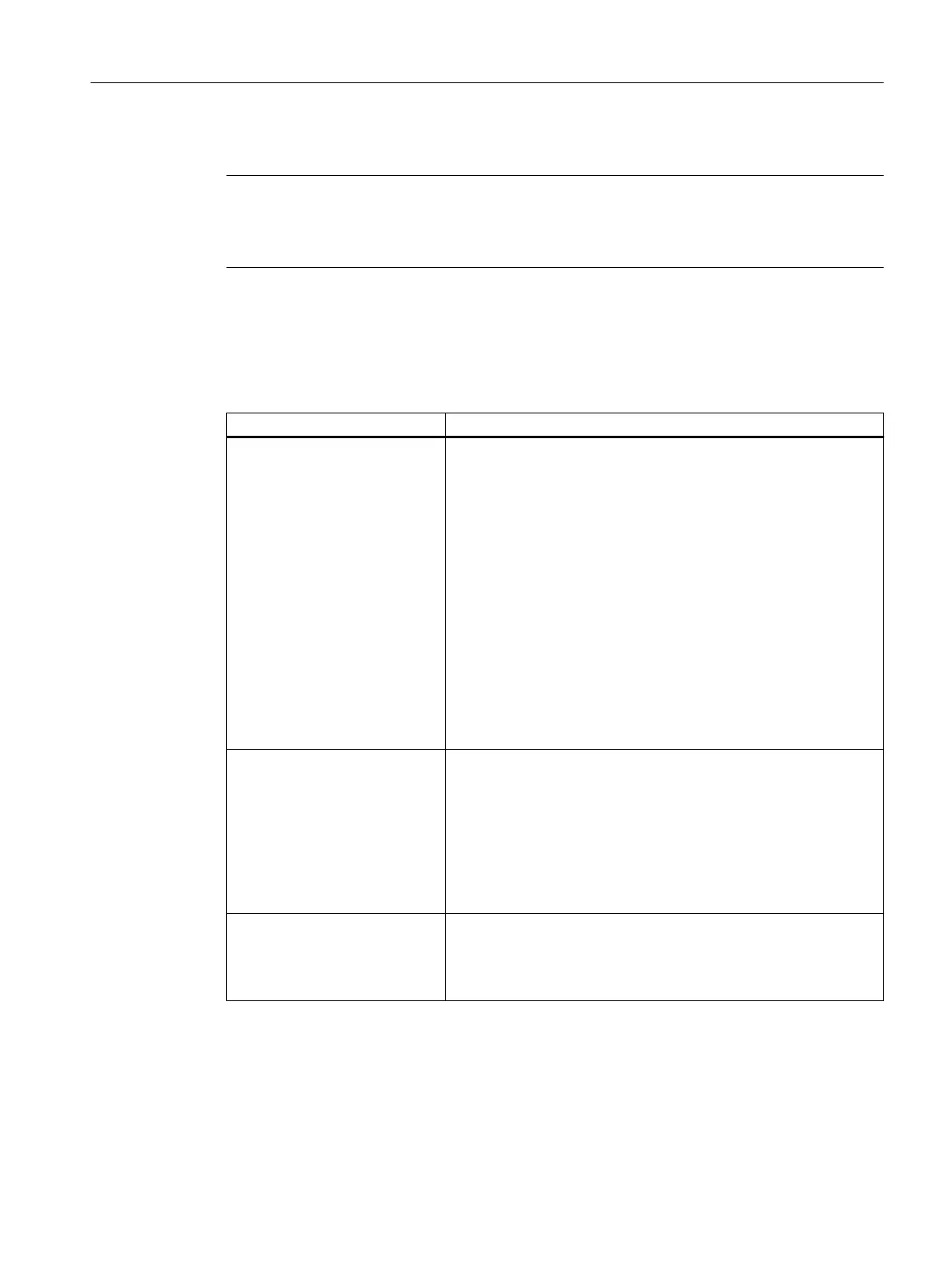

Technology Technology cycle

Drilling

● CYCLE81 - drilling, centering (Page 1064)

● CYCLE82 - drilling, counterboring (Page 1065)

● CYCLE85 - reaming (Page 1074)

● CYCLE86 - boring (Page 1075)

● CYCLE83 – deep-hole drilling 1 (Page 1068)

● CYCLE830 - deep-hole drilling 2 (Page 1101)

● CYCLE84 - tapping without compensating chuck (Page 1071)

● CYCLE840 - tapping with compensating chuck (Page 1110)

● CYCLE78 - Drill thread milling (Page 1060)

● CYCLE802 - arbitrary positions (Page 1099)

● HOLES1 – row position pattern (Page 1027)

● CYCLE801 – grid or frame position pattern (Page 1097)

● HOLES2 – circle or pitch circle position pattern (Page 1027)

Turning

● CYCLE951 - stock removal (Page 1121)

● CYCLE930 - groove (Page 1116)

● CYCLE940 – undercut form E and F / undercut thread

(Page 1118)

● CYCLE99 - thread turning (Page 1084)

● CYCLE98 - thread chain (Page 1080)

● CYCLE92 - cut-off (Page 1076)

Contour turning

● CYCLE62 - contour call (Page 1046)

● CYCLE952 – stock removal / residual stock removal / plunge

cutting / residual plunge cutting / plunge turning / residual plunge

turning (Page 1124)

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1025

Loading...

Loading...