3.7 Special motion commands

3.7.1 Approaching coded positions (CAC, CIC, CDC, CACP, CACN)

Using the path commands to "Approach coded positions", it is possible to traverse linear and

rotary axes to fixed axis positions saved in the machine data table by specifying position

numbers.

Syntax

CAC(<n>)

CIC(<n>)

CACP(<n>)

CACN(<n>)

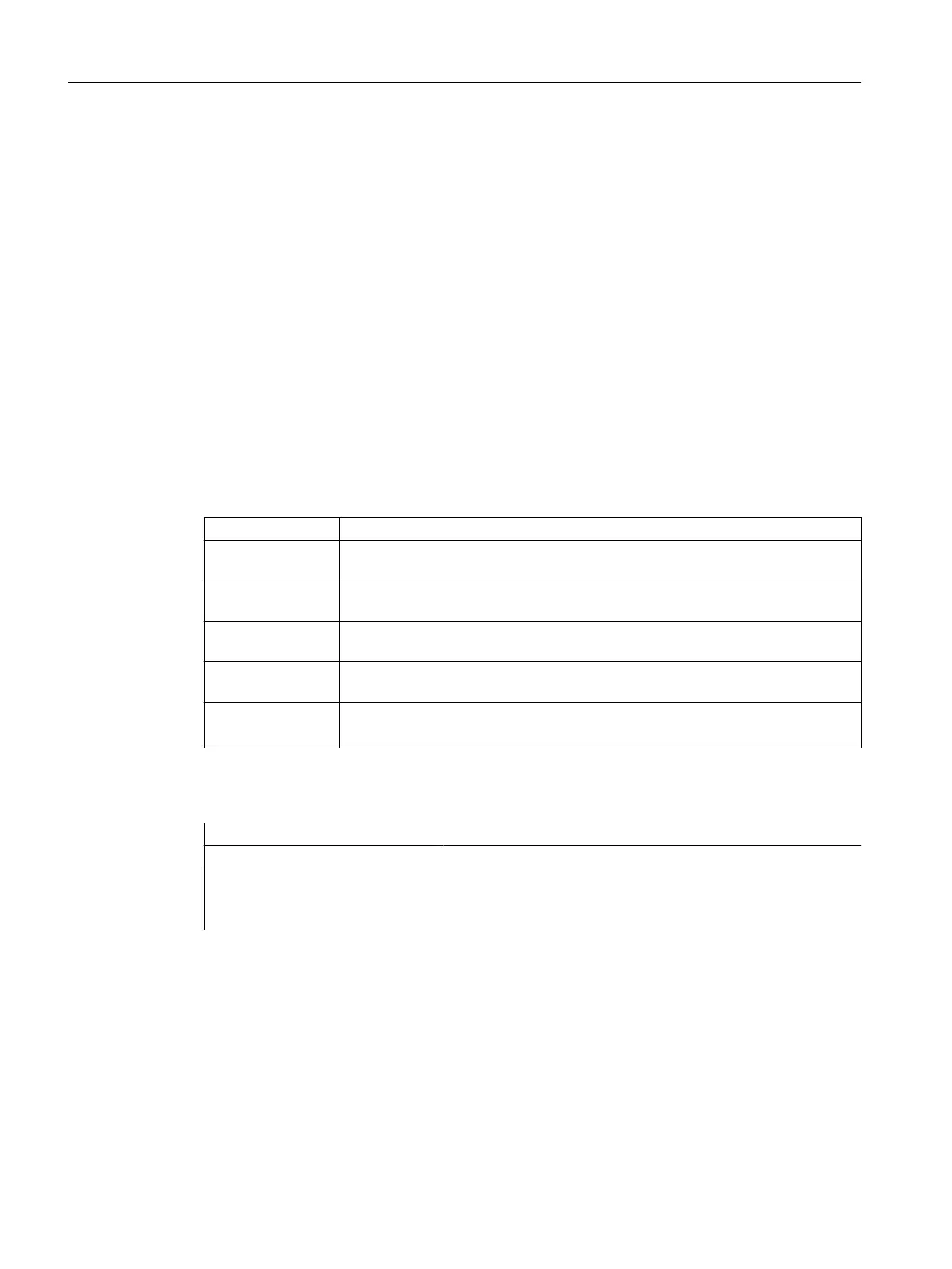

Meaning

CAC(<n>): Approach coded position from position number n

CIC(<n>): Starting from the actual position number, approach the coded position n position

locations before (+n) or back (–n)

CDC(<n>): Approach the position from position number n along the shortest path

(only for rotary axes)

CACP(<n>): Approach coded position from position number n in the positive direction

(only for rotary axes)

CACN(<n>): Approach coded position from position number n in the negative direction

(only for rotary axes)

<n>: Position number within the machine data table

Value range: 0, 1, … (max. number of table locations - 1)

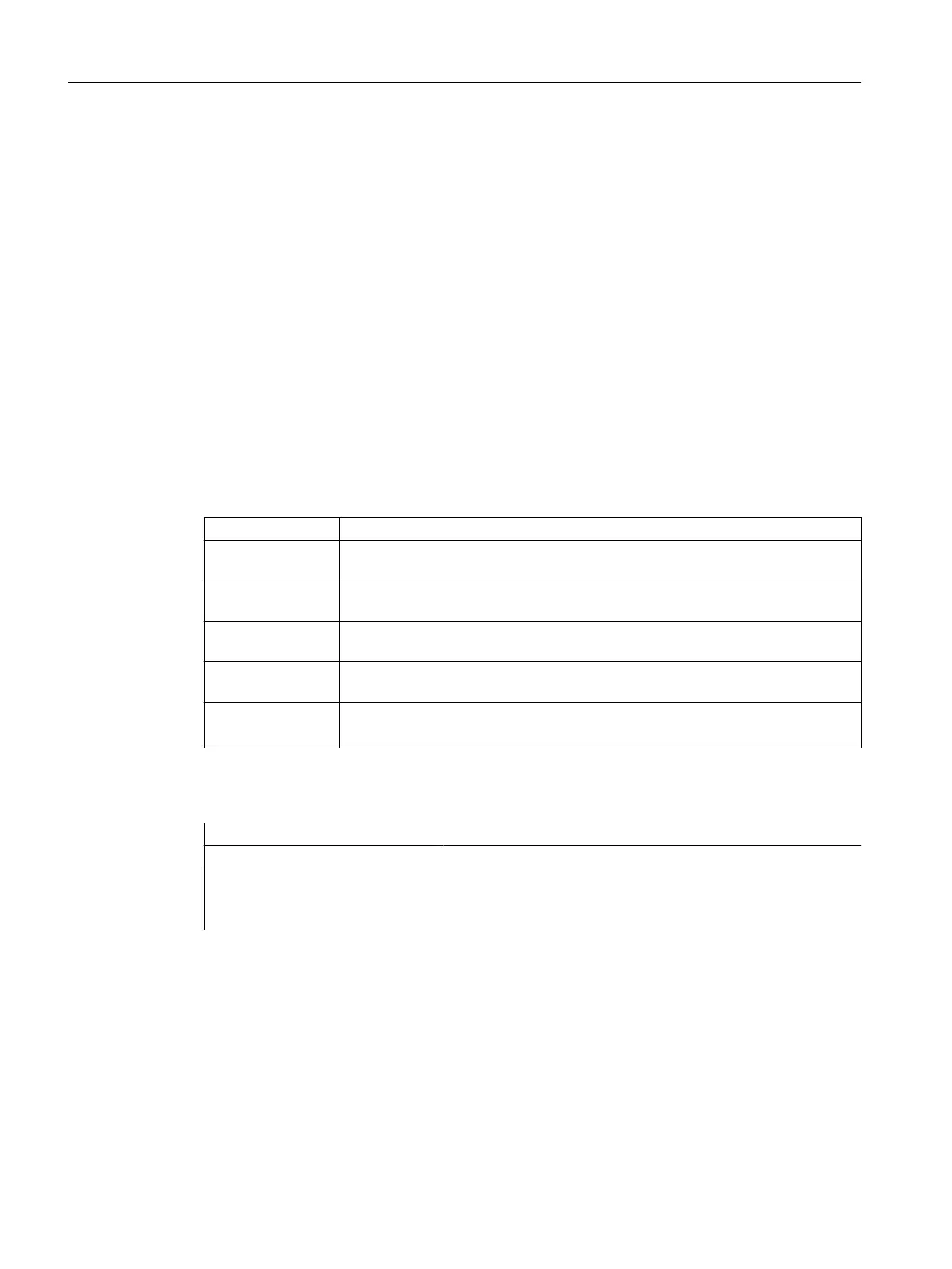

Example: Approach coded positions of a positioning axis

Programming code Comment

N10 FA[B]=300 ; Feedrate for positioning axis B

N20 POS[B]=CAC(10) ; Approach coded position from position number 10

N30 POS[B]=CIC(-4) ; Approach coded position from "current position num-

ber" - 4

3.7.2 Spline interpolation (ASPLINE, BSPLINE, CSPLINE, BAUTO, BNAT, BTAN,

EAUTO, ENAT, ETAN, PW, SD, PL)

Randomly curved workpiece contours cannot be precisely defined in an analytic form. This is

the reason why these type of contours are approximated using a limited number of points along

curves, e.g. when digitizing surfaces. The points along the curve must be connected to define

a contour in order to generate the digitized surface of a workpiece. Spline interpolation permits

this.

Work preparation

3.7 Special motion commands

NC programming

592 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...