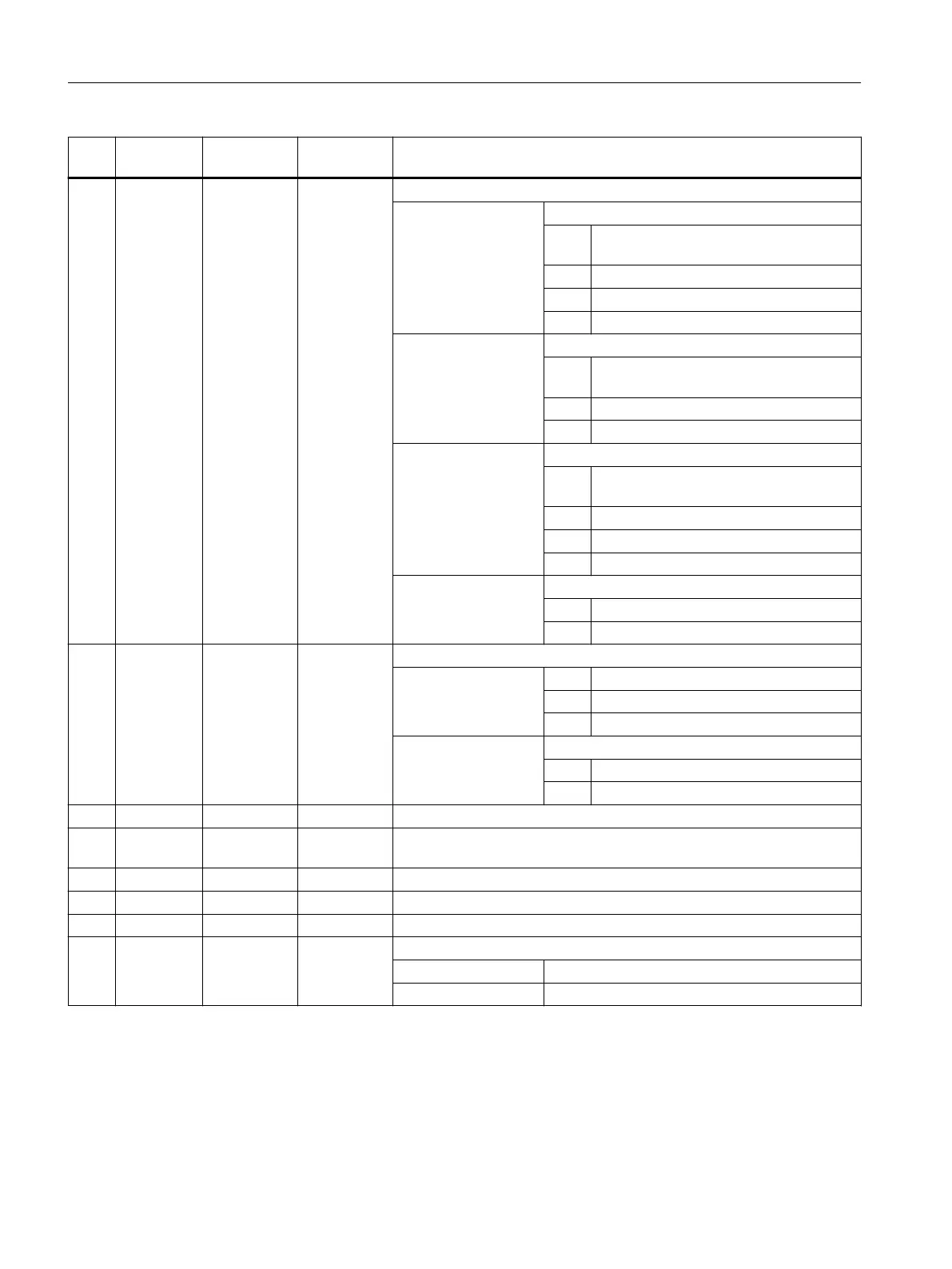

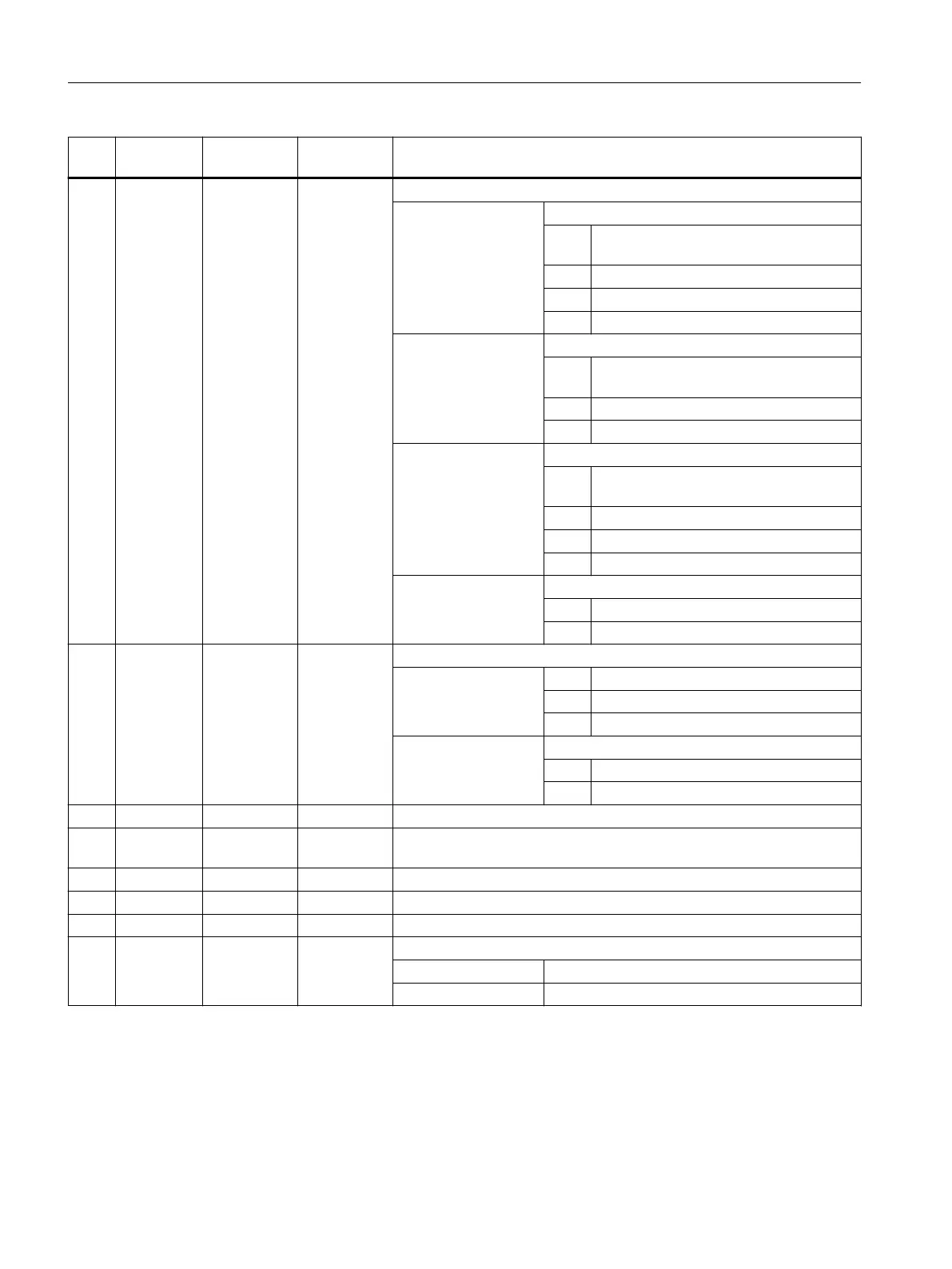

No. Parameter

mask

Parameter

internal

Data type Meaning

15 <_TECHNO> INT Technology

1)

UNITS: Exact stop response

0 = Exact stop response active as before cy‐

cle call

1 = Exact stop G601

2 = Exact stop G602

3 = Exact stop G603

TENS: Feedforward control

0 = With/without feedforward control active

as before cycle call

1 = With feedforward control FFWON

2 = Without feedforward control FFWOF

HUNDREDS: Acceleration

0 = SOFT/BRISK/DRIVE active as before cy‐

cle call

1 = With jerk limitation SOFT

2 = Without jerk limitation BRISK

3 = Reduced acceleration DRIVE

THOUSANDS: MCALL spindle mode

0 = Reactivate spindle operation for MCALL

1 = For MCALL remain in position control

16 <_VARI> INT Machining type

UNITS: 0 = 1 cut

1 = Chip breaking (deep hole tapping)

2 = Chip removal (deep hole tapping)

THOUSANDS: ISO/SIEMENS mode not relevant for screen form

0 = Call from ISO compatibility

1 = Call from SIEMENS context

17 D <_DAM> REAL Maximum depth infeed (for chip removal/breaking only)

18 V2 <_VRT> REAL Retraction distance after each machining step (for chip breaking only),

see <_AMODE>

19 <_PITM> STRING[15] String as marker for pitch input

2)

20 <_PTAB> STRING[5] String for thread table ("", "ISO", "BSW", "BSP", "UNC")

2)

21 <_PTABA> STRING[20] String for selection from thread table (e.g. "M 10", "M 12", ...)

2)

22 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

Work preparation

3.25 Programming cycles externally

NC programming

1072 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...