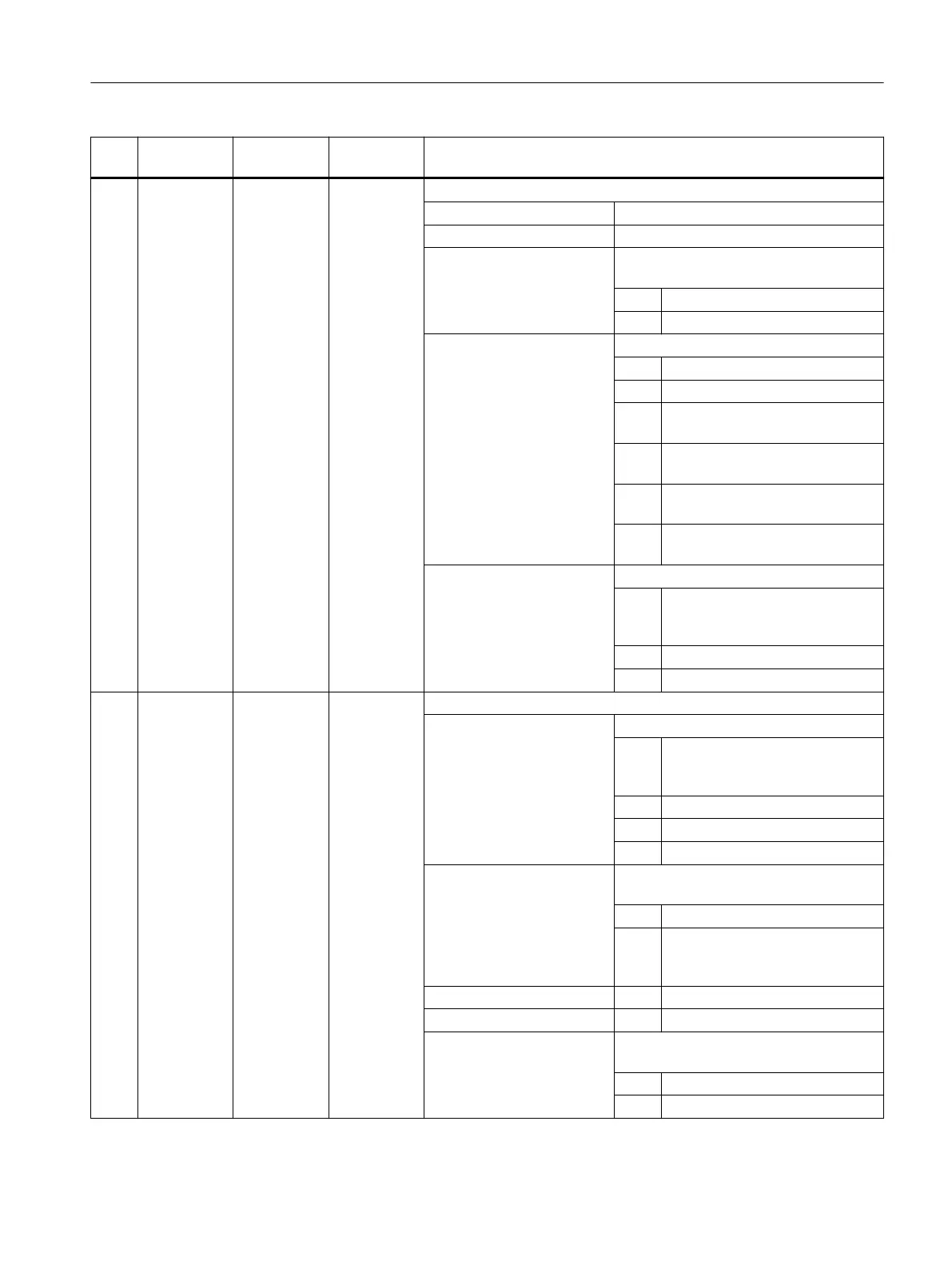

No. Parameter

mask

Parameter

internal

Data type Meaning

27 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Select machining/only calculation of start

point

0 = Compatibility mode

1 = Normal machining

THOUSANDS: Dimensioning via center/corner

0 = Compatibility mode

1 = Dimensioning via center

2 = Dimensioning of corner point,

pocket position +LENG/+WID

3 = Dimensioning of corner point,

pocket position -LENG/+WID

4 = Dimensioning of corner point,

pocket position +LENG/-WID

5 = Dimensioning of corner point,

pocket position -LENG/-WID

TEN THOUSANDS: Complete machining/remachining

0 = Compatibility mode

(process <_AP1>, <_AP2>

and <_AD> as before)

1 = Complete machining

2 = Post machining

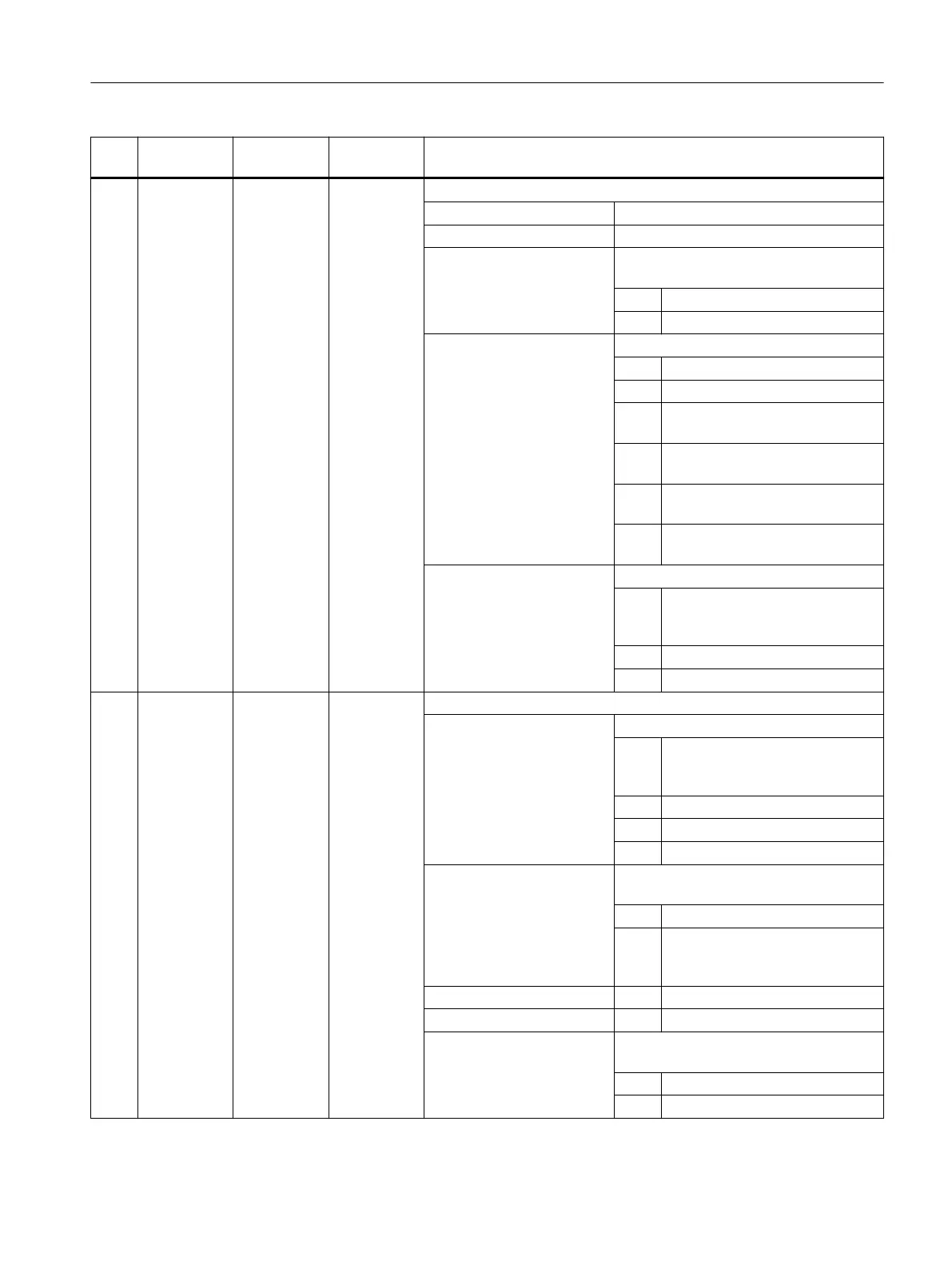

28 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

TENS: Type of feedrate: G group (G94/G95) for

surface and depth feedrate

0 = Compatibility mode

1 = G command as before cycle call.

G94/G95 same for surface and

depth feedrate

HUNDREDS: --- Reserved

THOUSANDS: --- Reserved

TEN THOUSANDS: Technology scaling in cycle screen forms

(Page 1153)

0 = Input: Complete

1 = Input: Simple

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1031

Loading...

Loading...