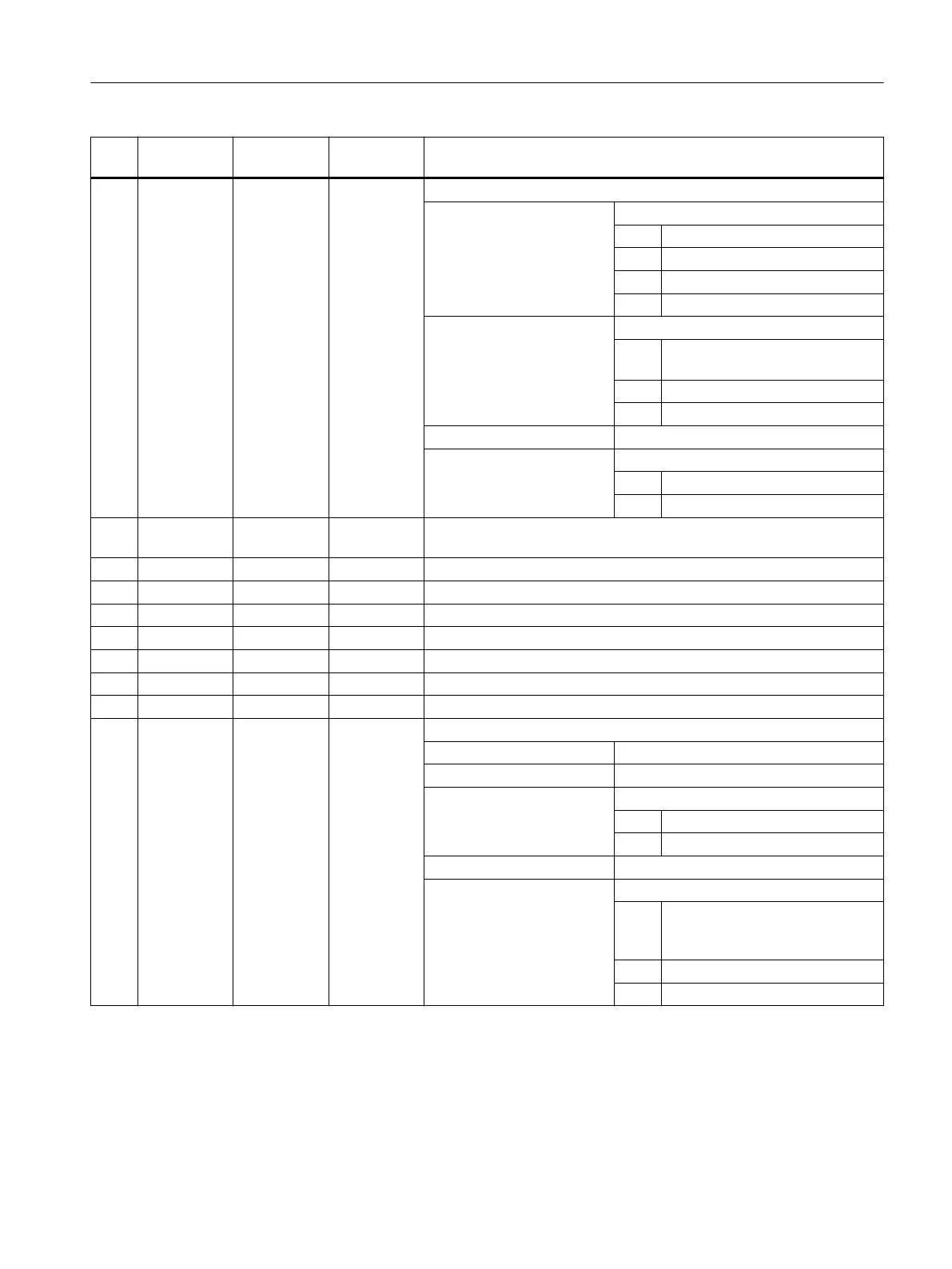

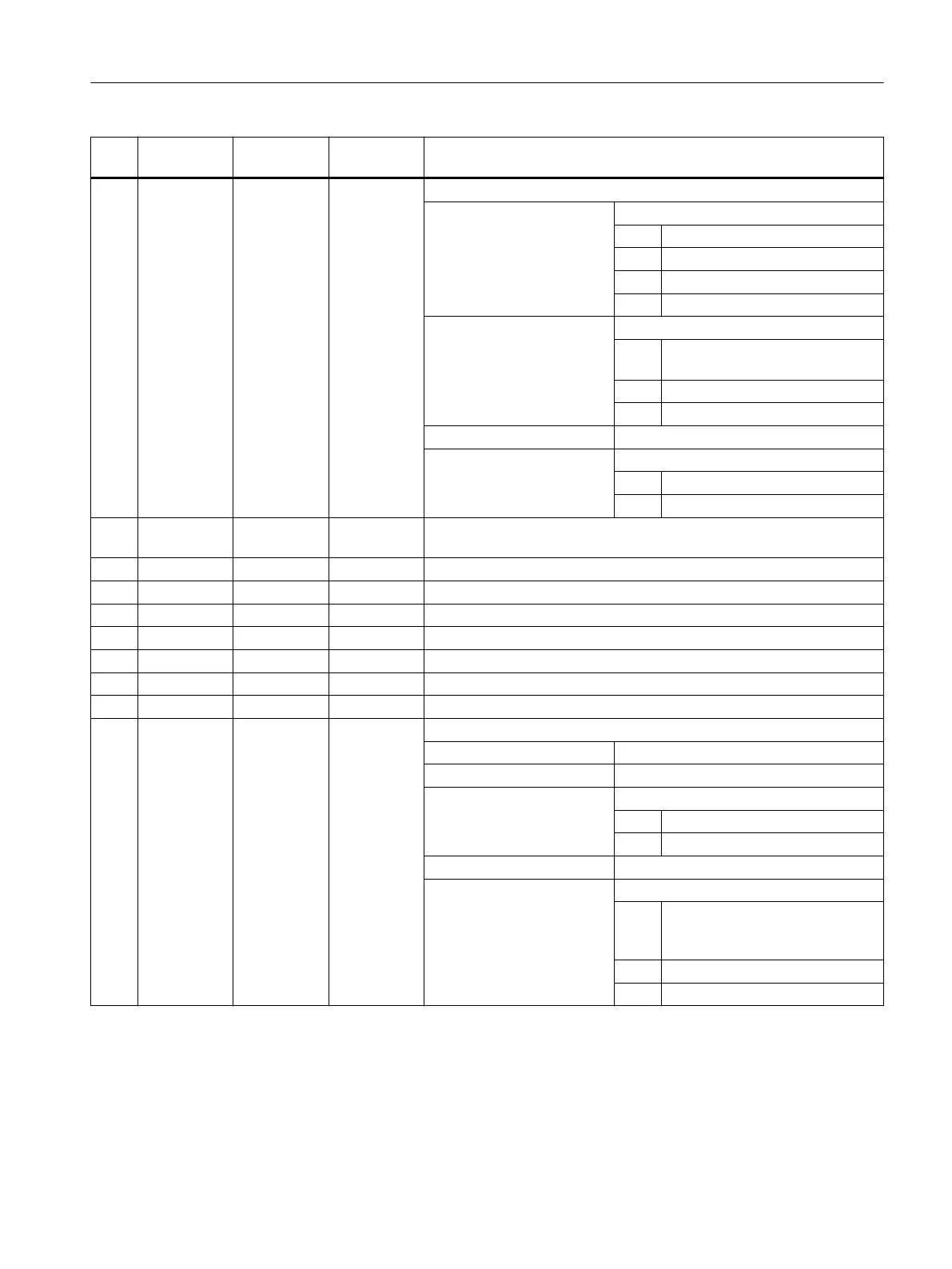

No. Parameter

mask

Parameter

internal

Data type Meaning

14 <_VARI> INT Machining type

UNITS: Machining

1 = Roughing

2 = Finishing

4 = Edge finishing

5 = Chamfering

TENS: Infeed type (roughing and finishing)

0 = Predrilled, infeed with G0 (pocket

is premachined)

1 = Vertically, infeed with G1

2 = Helical

HUNDREDS: Reserved

THOUSANDS:

0 = Plane-by-plane

1 = Helical

15 DXY <_MIDA> REAL Maximum plane infeed, see <_AMODE>,

0 = 0.8 x tool diameter

16 ∅ <_AP1> REAL Diameter/radius of premachining (inc)

17 AZ <_AD> REAL Depth of premachining (inc)

18 ER <_RAD1> REAL Radius of helical path on helical insertion

19 EP <_DP1> REAL Helical pitch on insertion on helical path

20 <_UMODE> INT Reserved

21 FS <_FS> REAL Chamfer width (inc)

22 ZFS <_ZFS> REAL Insertion depth (tool tip) on chamfering (abs/inc), see <_AMODE>

23 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Machining/calculation of start point

0 = Compatibility mode

1 = Normal machining

THOUSANDS: Reserved

TEN THOUSANDS: Complete machining/remachining

0 = Compatibility mode

(process <_AP1> and <_AD> as

before)

1 = Complete machining

2 = Post machining

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1033

Loading...

Loading...