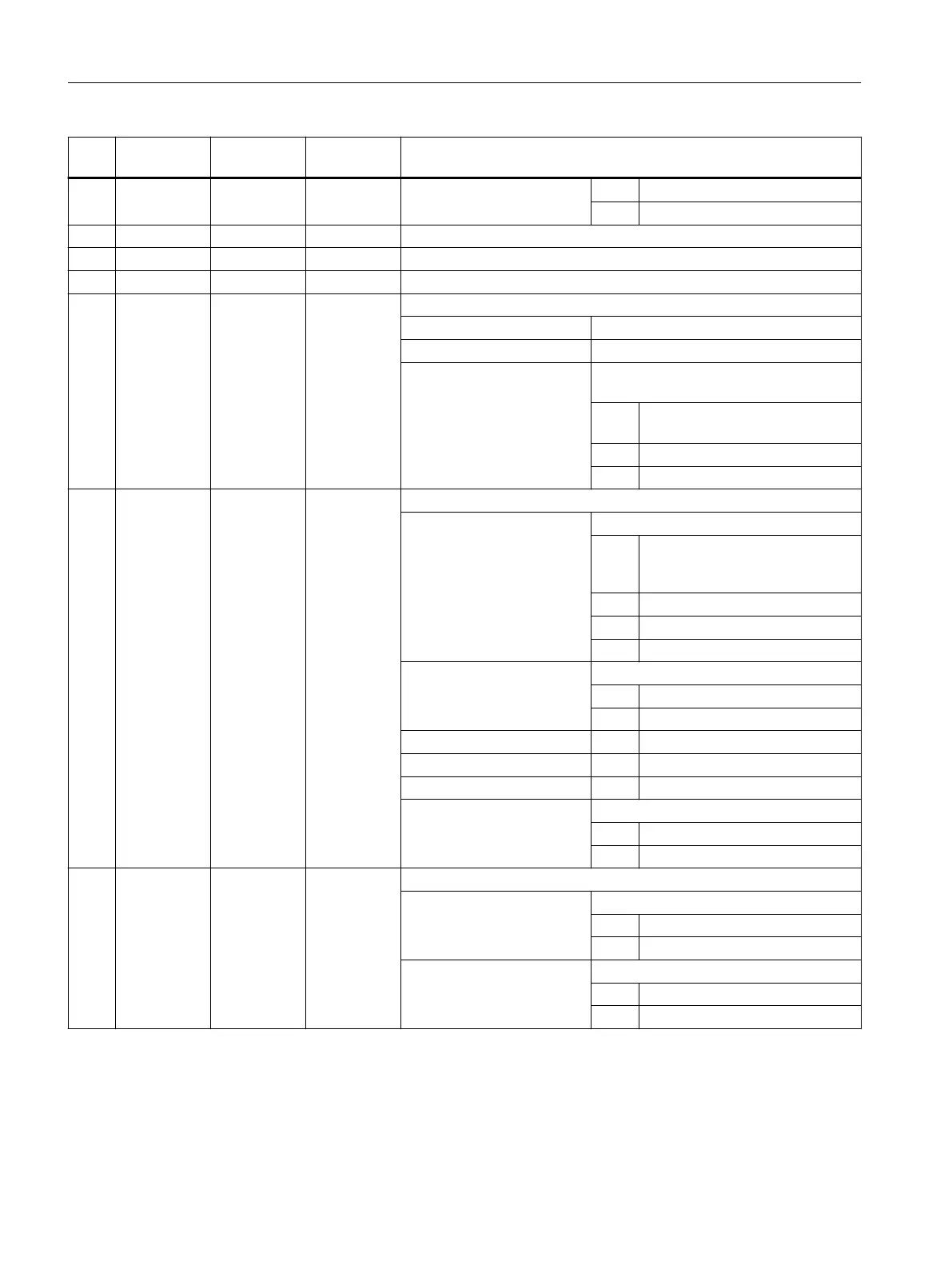

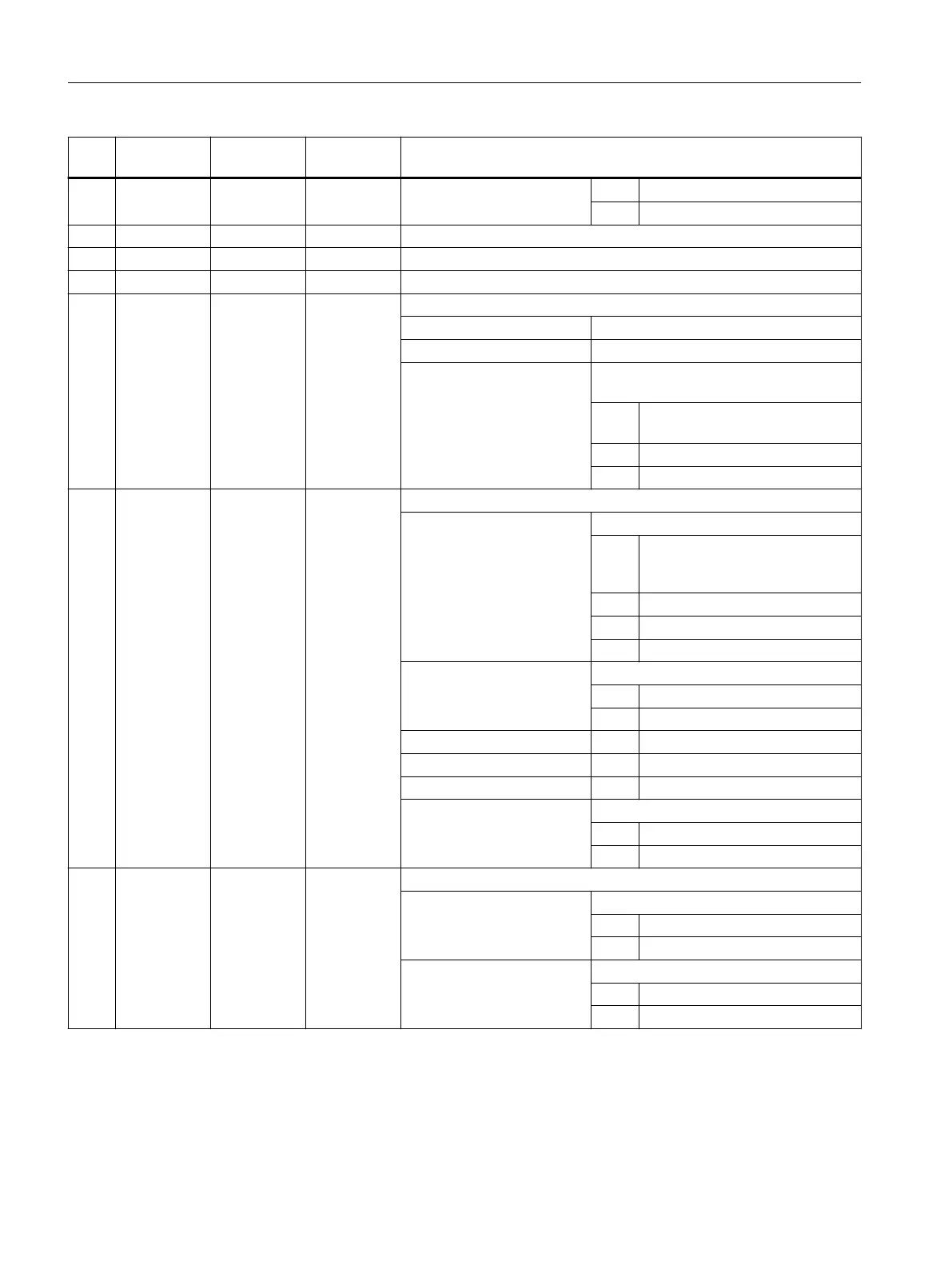

No. Parameter

mask

Parameter

internal

Data type Meaning

11 <_CDIR> INT Milling direction 0 = Down-cut

1 = Up-cut

12 TR <_TR> STRING[20] Reference tool name

13 DR <_DR> INT Reference tool D number

14 <_UMODE> INT Reserved

15 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Select machining/only calculation of start

point

0 = Normal machining (no compatibil‐

ity mode needed)

1 = Normal machining

2 = Reserved

25 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

TENS: Technology mode

1 = Predrilling

2 = Centering

HUNDREDS: --- Reserved

THOUSANDS: --- Reserved

TEN THOUSANDS: --- Reserved

HUNDRED THOUSANDS: Automatic program name

0 = No

1 = Yes

26 <_AMODE> INT Alternative mode

UNITS: Drilling/centering depth Z1

0 = Absolute (compatibility mode)

1 = Incremental

TENS: Unit for plane infeed (DXY)

0 = mm

1 = % of tool diameter

Work preparation

3.25 Programming cycles externally

NC programming

1050 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...