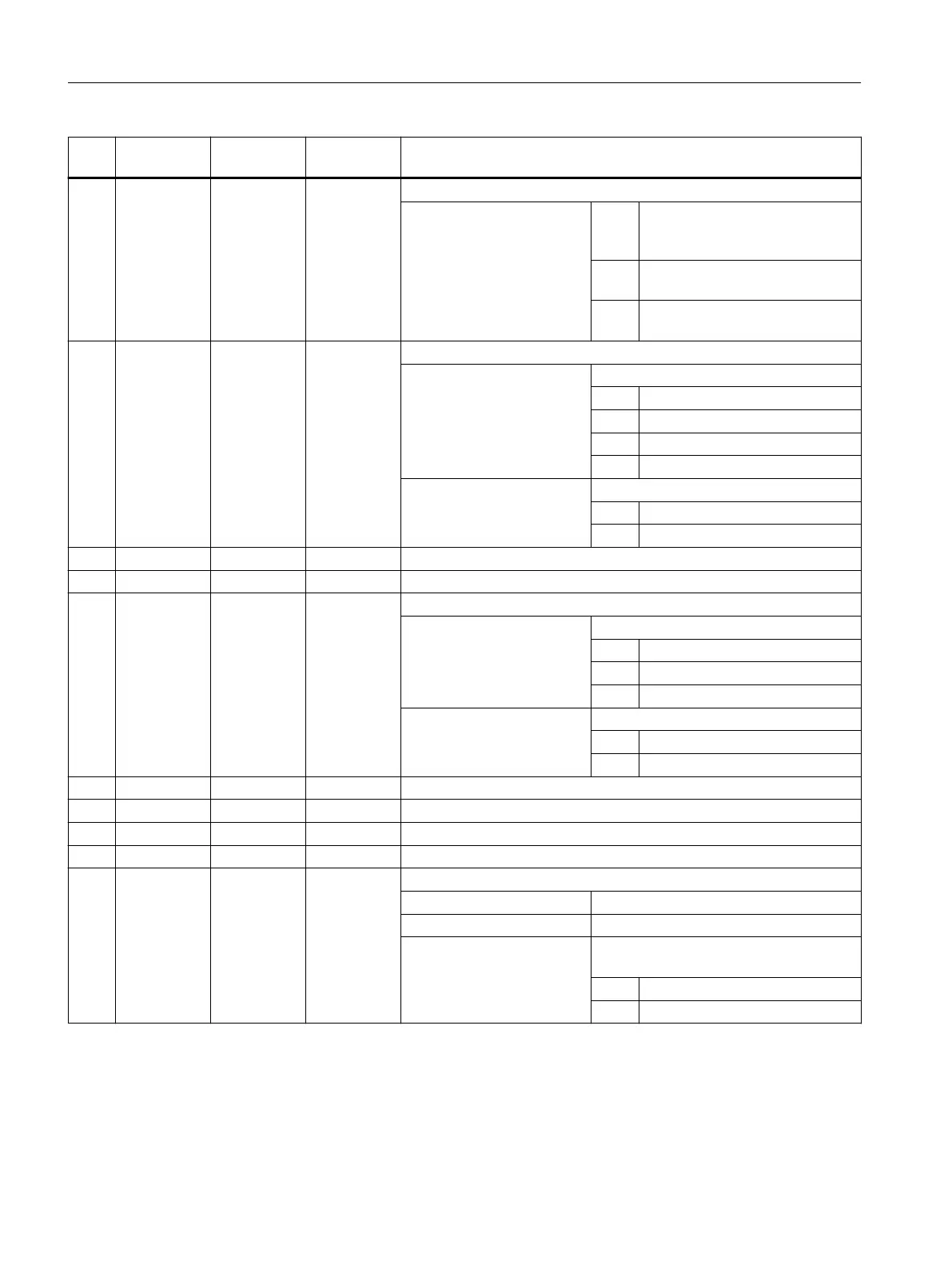

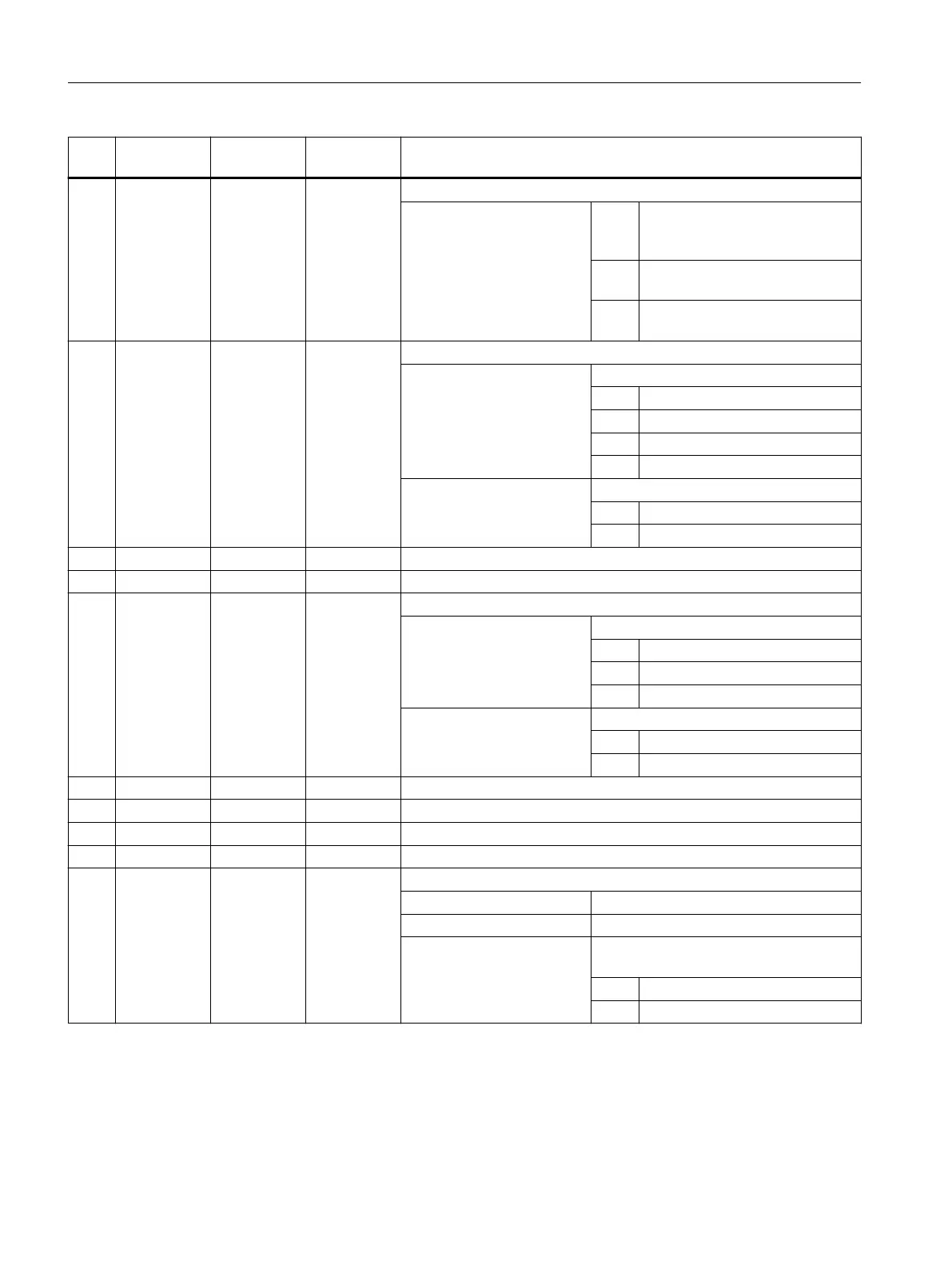

No. Parameter

mask

Parameter

internal

Data type Meaning

12 <_RL> INT Machining direction

40 = Center of contour (G40, ap‐

proach and retract: straight line

or vertical)

41 = Left of contour (G41, approach

and retract: straight line or circle)

42 = Right of contour (G42, approach

and retract: straight line or circle)

13 <_AS1> INT Contour approach movement

UNITS:

1 = Straight line

2 = Quadrant

3 = Semi-circle

4 = Approach and retraction vertically

TENS:

0 = Last movement, in the plane

1 = Last movement, spatial

14 L1 <_LP1> REAL Approach path or approach radius (inc; enter without sign)

15 FZ <_FF3> REAL Feedrate for intermediate paths (G94/G95 as to contour)

16 <_AS2> INT Contour approach movement (not vertical approach/retract)

UNITS:

1 = Straight line

2 = Quadrant

3 = Semi-circle

TENS:

0 = Last movement, in the plane

1 = Last movement, spatial

17 L2 <_LP2> REAL Retract path or retract radius (inc, to be entered without sign)

18 <_UMODE> INT Reserved

19 FS <_FS> REAL Chamfer width (inc)

20 ZFS <_ZFS> REAL Insertion depth (tool tip) on chamfering (abs/inc), see <_AMODE>

21 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Select machining/only calculation of start

point

0 = Compatibility mode

1 = Normal machining

Work preparation

3.25 Programming cycles externally

NC programming

1054 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...