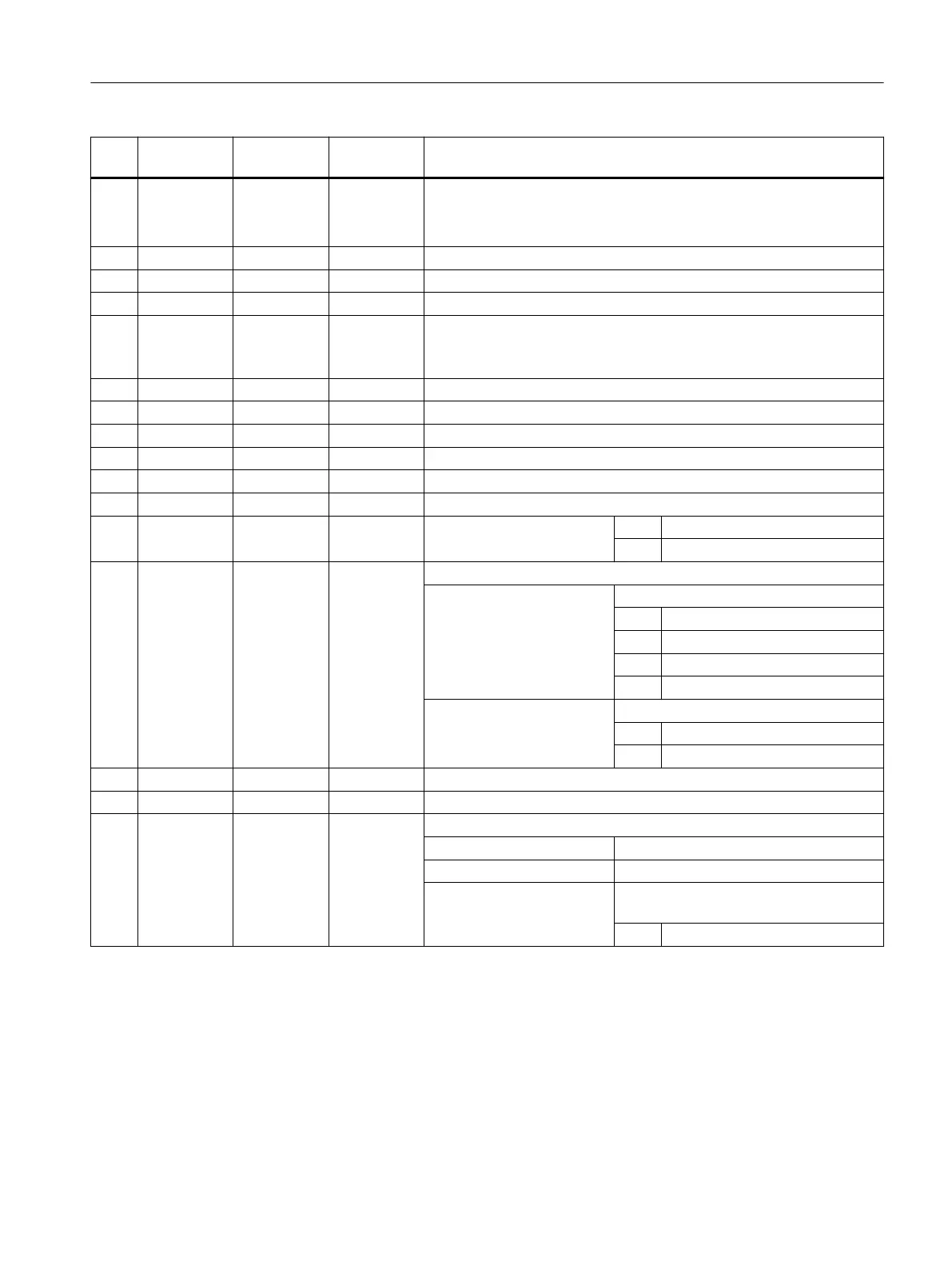

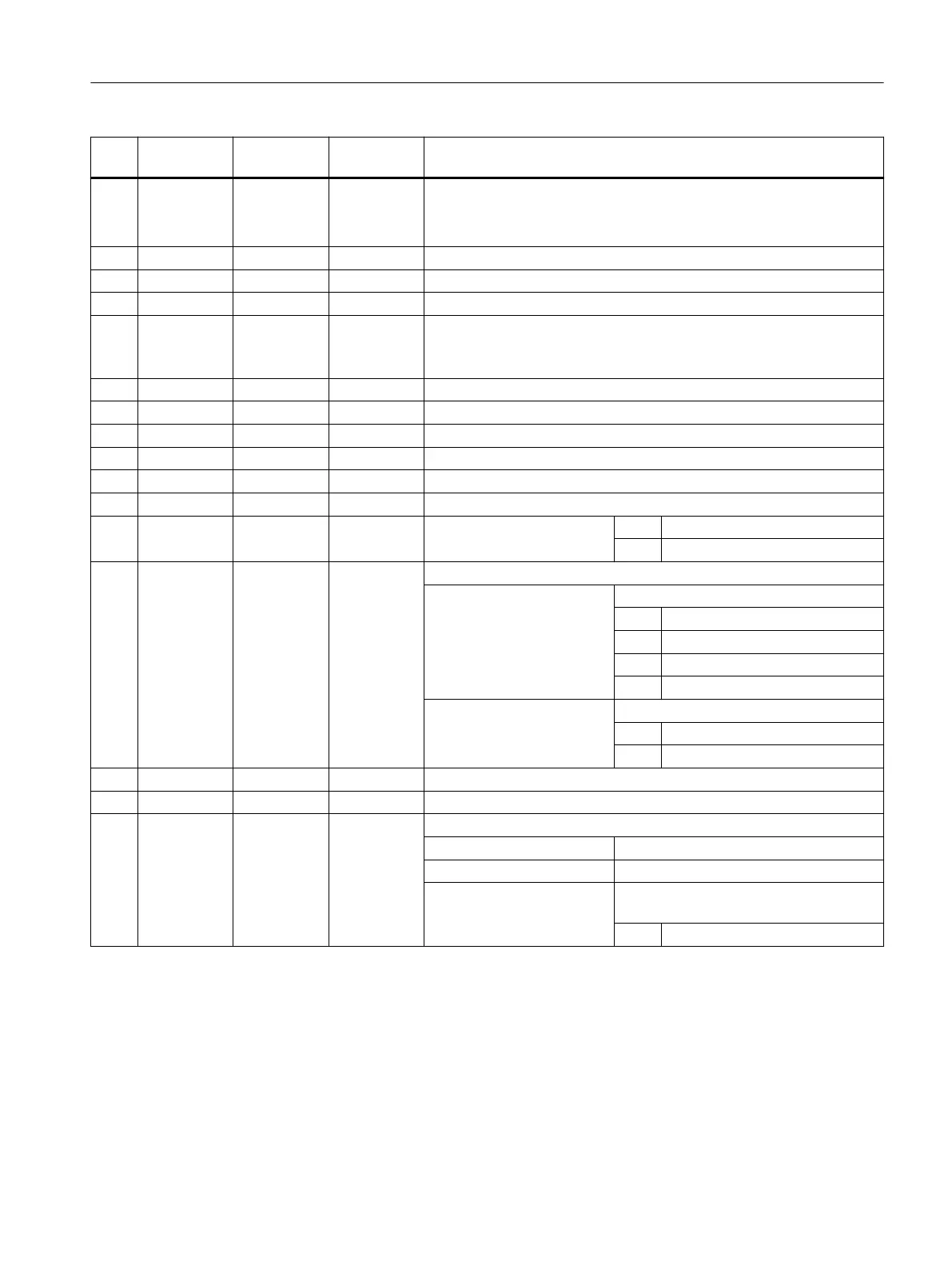

No. Parameter

mask

Parameter

internal

Data type Meaning

6

SW/L <_SWL> REAL Width across flats or edge length (depending on <_VARI>)

("SW" for width across flats, "L" for edge length)

Width across flats only if even number of edges, and single edge

7 X0 <_PA> REAL Spigot reference point, 1st axis (abs)

8 Y0 <_PO> REAL Spigot reference point, 2nd axis (abs)

9 α0 <_STA> REAL Angle of rotation, center of edge against 1st axis (X axis)

10 R1/FS1 <_RC> REAL Corner rounding with <_NUM> > 2 (radius/chamfer, see <_AMODE>)

(inc, to be entered without sign)

("R1" for radius, "FS1" for chamfer)

11 ∅ <_AP1> REAL Unmachined diameter of spigot

12 DXY <_MIDA> REAL Maximum infeed width (for unit, see <_AMODE>)

13 DZ <_MID> REAL Maximum depth infeed

14 UXY <_FAL> REAL Finishing allowance, plane

15 UZ <_FALD> REAL Finishing allowance, depth

16 F <_FFP1> REAL Machining feedrate

17 <_CDIR> INT Milling direction 0 = Down-cut

1 = Up-cut

18 <_VARI> INT Machining type

UNITS: Machining

1 = Roughing

2 = Finishing

3 = Edge finishing

5 = Chamfering

TENS: Width across flats or edge length

0 = Width across flats

1 = Edge length

19 FS <_FS> REAL Chamfer width (inc)

20 ZFS <_ZFS> REAL Insertion depth (tool tip) on chamfering (abs/inc), see <_AMODE>

21 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Select machining or just calculation of

start point

1 = Normal machining

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1063

Loading...

Loading...