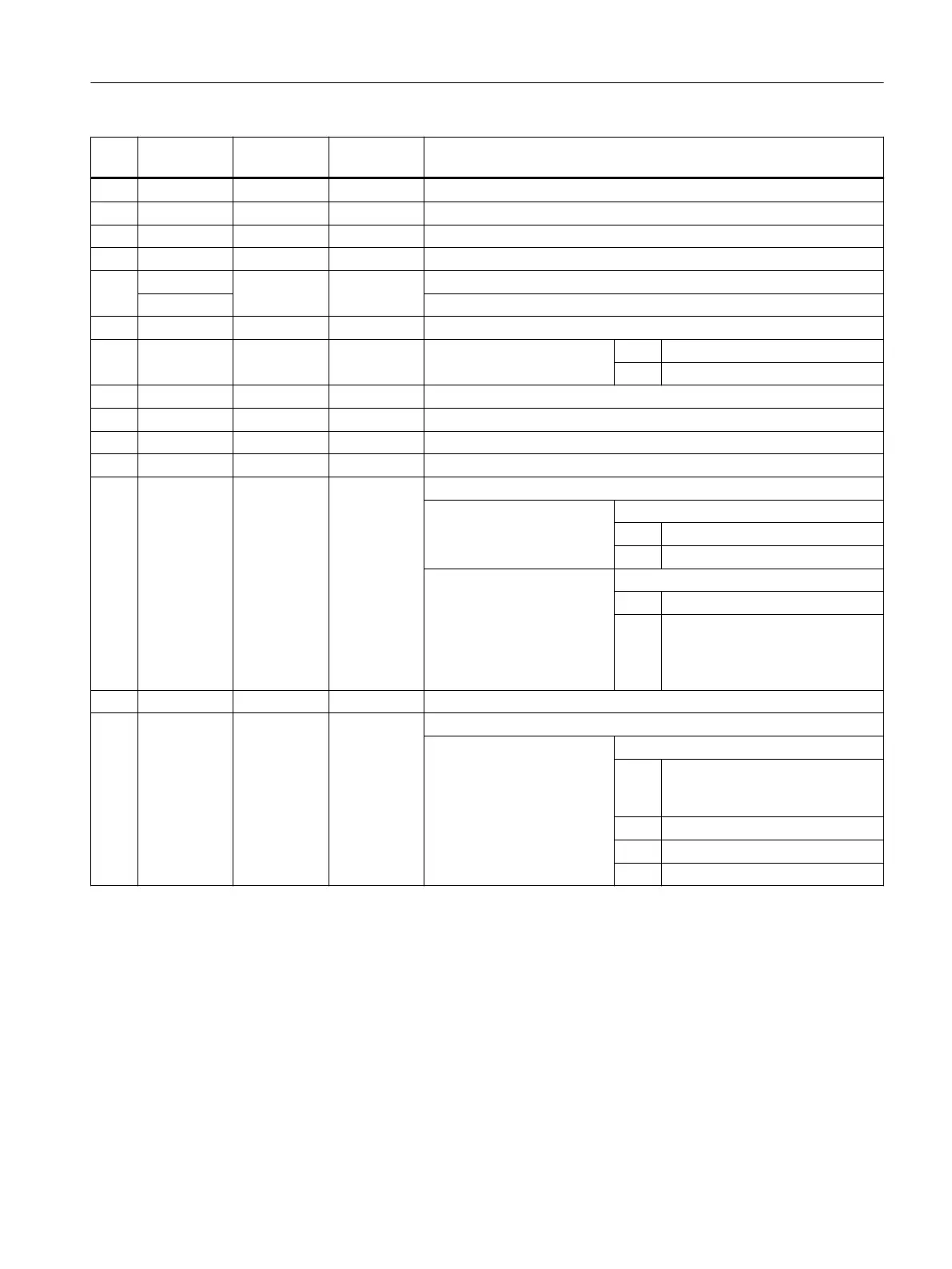

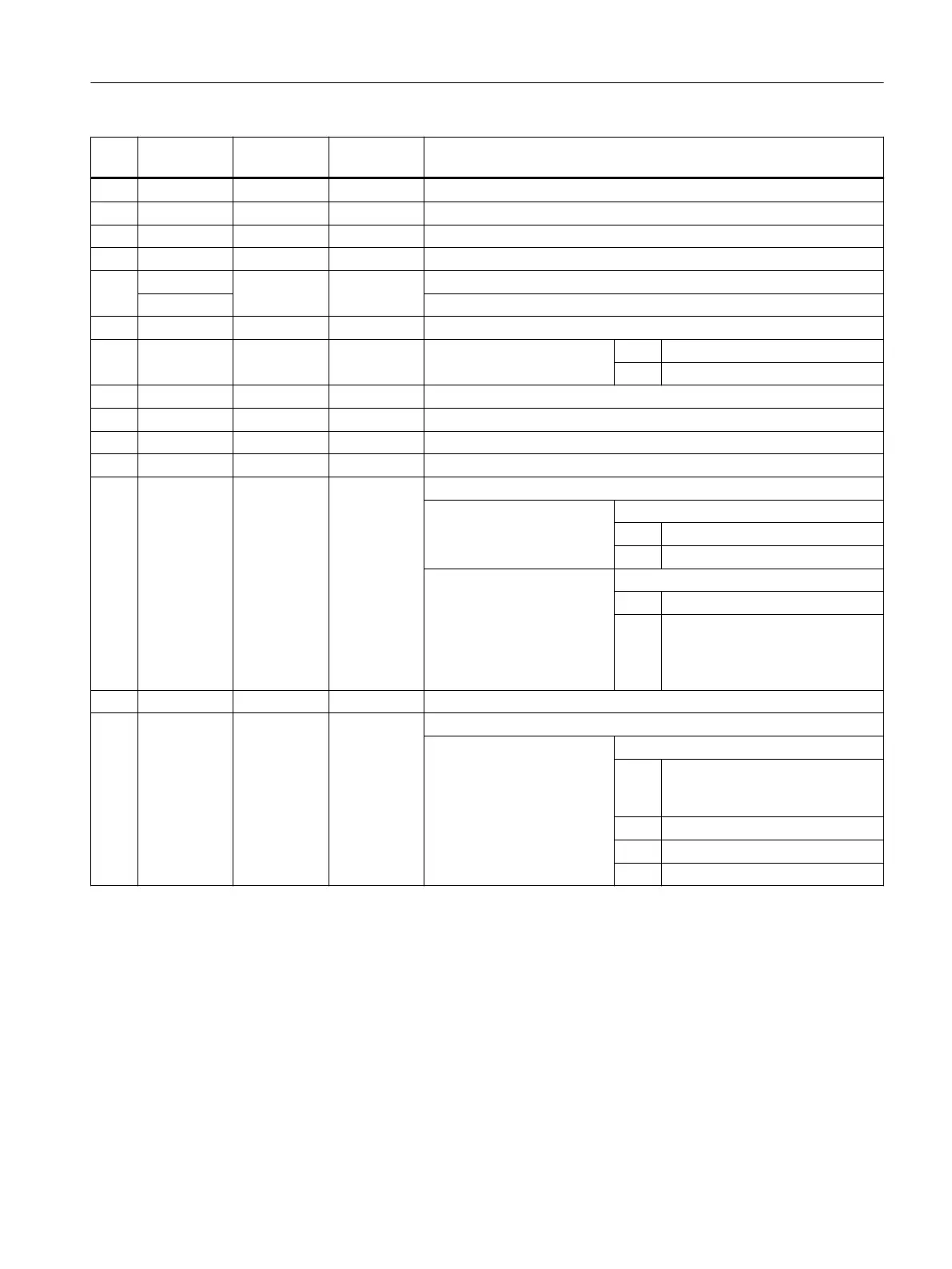

No. Parameter

mask

Parameter

internal

Data type Meaning

3 X1 <_DIAG1> REAL Depth for speed reduction, see <_AMODE> (UNITS)

4 X2 <_DIAG2> REAL Final depth, see <_AMODE> (TENS)

5 R/FS <_RC> REAL Rounding status or chamfer width, see <_AMODE> (THOUSANDS)

6 SC <_SDIS> REAL Safety clearance (to be added to reference point, enter without sign)

7 S <_SV1> REAL Constant spindle speed, see <_AMODE> (TEN THOUSANDS)

V Constant cutting rate

8 SV <_SV2> REAL Maximum speed at constant cutting speed

9 DIR <_SDAC> INT Direction of spindle rotation 3 = For M3

4 = For M4

10 F <_FF1> REAL Infeed as far as depth for speed reduction

11 FR <_FF2> REAL Reduced infeed as far as final depth

12 SR <_SS2> REAL Reduced speed as far as final depth

13 XM <_DIAGM> REAL Depth to withdraw parts gripper (abs, always diameter)

14 <_VARI> INT Machining type

UNITS: Retraction

0 = Retraction to <_SPD> + <_SDIS>

1 = No retraction at the end

TENS: Parts gripper

0 = No, do not execute M command

1 = Yes, call from CUST_TECH‐

CYC(101)- open drawer,

CUST_TECHCYC(102)- close

drawer

15 <_DN> INT D number for 2nd edge of tool; if not programmed ⇒ D+1

20 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1077

Loading...

Loading...