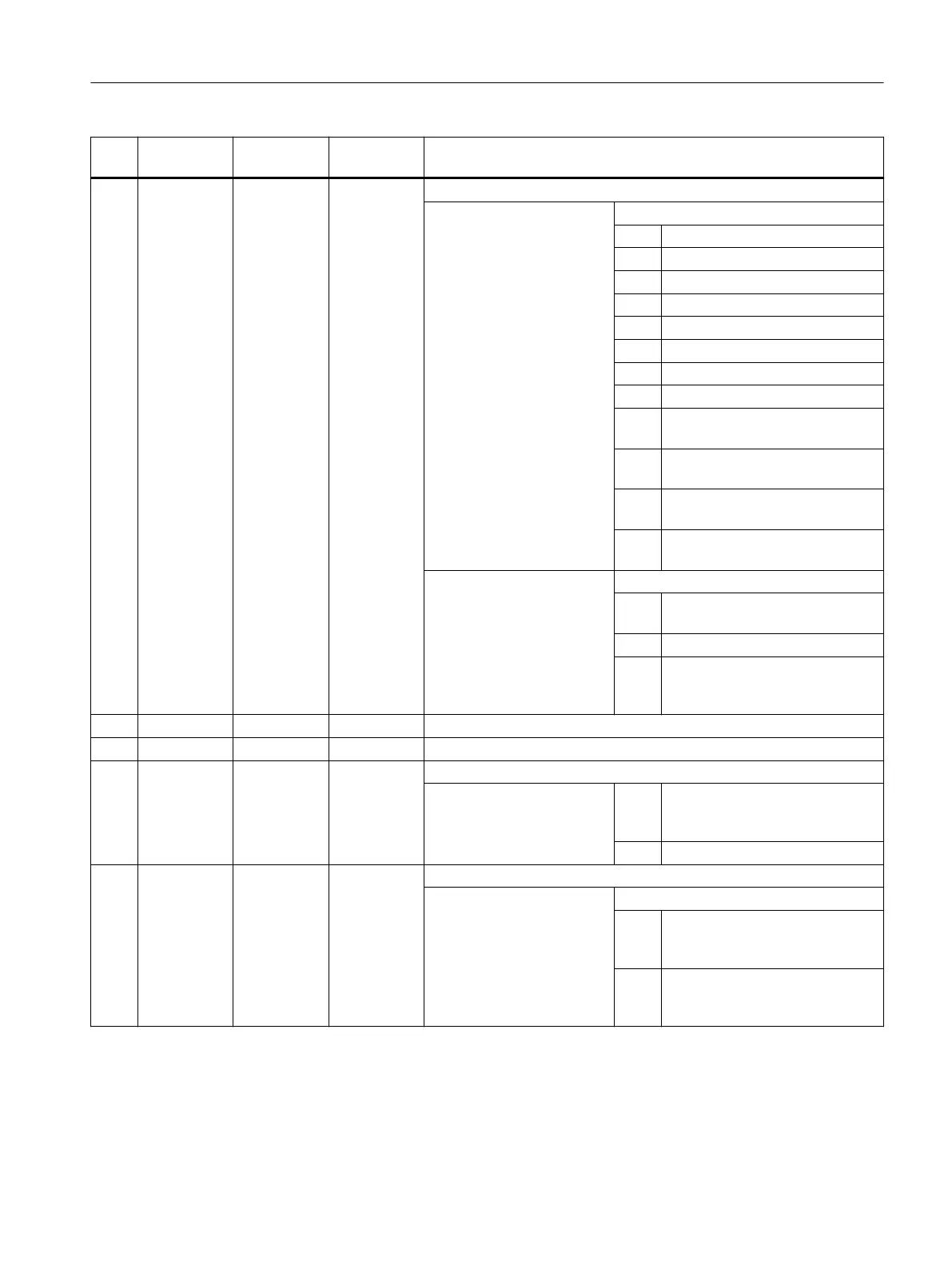

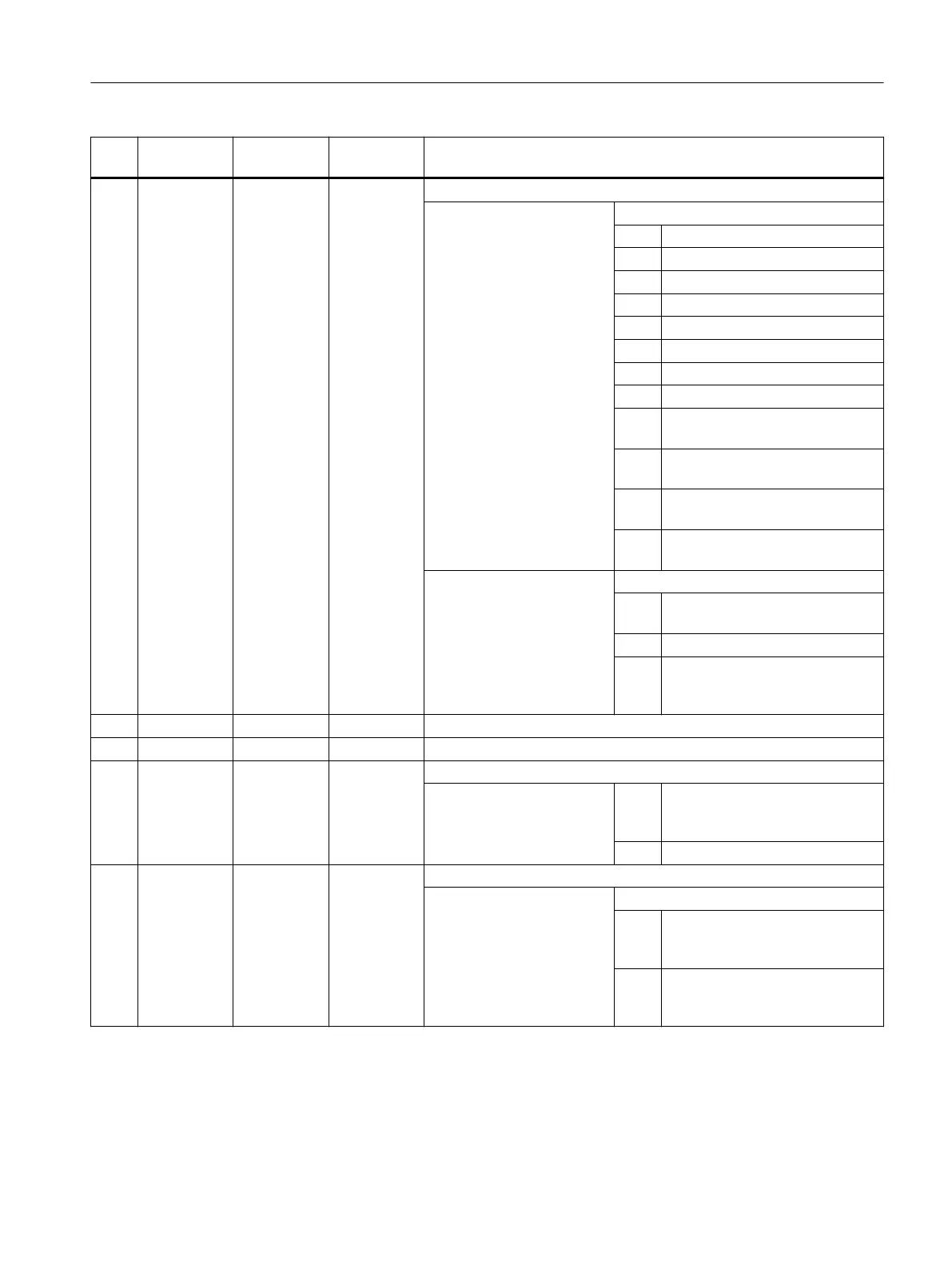

No. Parameter

mask

Parameter

internal

Data type Meaning

9 <_VARI> INT Machining type

UNITS and TENS:

1 = Roughing, longitudinal, external

2 = Roughing, transverse, external

3 = Roughing, longitudinal, internal

4 = Roughing, transverse, internal

5 = Finishing, longitudinal, external

6 = Finishing, transverse, external

7 = Finishing, longitudinal, internal

8 = Finishing, transverse, internal

9 = Complete machining, longitudi‐

nal, external

10 = Complete machining, transverse,

external

11 = Complete machining, longitudi‐

nal, internal

12 = Complete machining, transverse,

internal

HUNDREDS:

0 = With rounding at the contour,

without residual corners

1 = Without rounding at the contour

2 = Rounding only to previous inter‐

section, residual corners can re‐

sult

10 DT <DT> REAL Dwell time at feed interruption

11 DI <DAM> REAL Distance for feed interruptions

12 VRT <_VRT> REAL Lift-off distance from the contour

0 = A lift-off distance of 1 mm is used

internally regardless of the active

system (inch or metric)

> 0 = Lift-off distance

13 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Evaluation of the infeed depth

0 = Infeed depth is calculated

corresponding to the G group DI‐

AMON/DIAMOF

1 = Infeed depth acts as radius value

(independent of DIAMON/

DIAMOF)

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1079

Loading...

Loading...