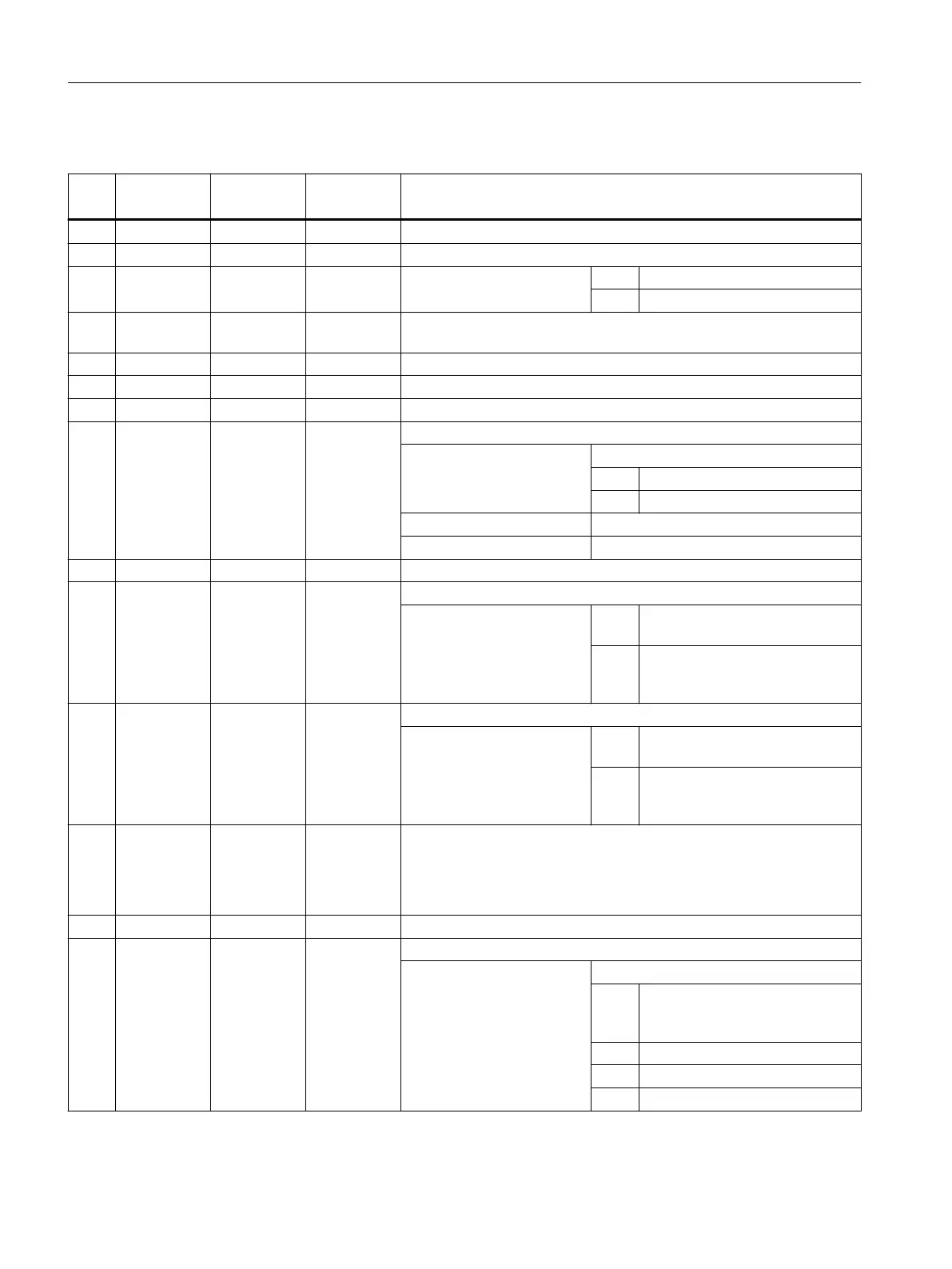

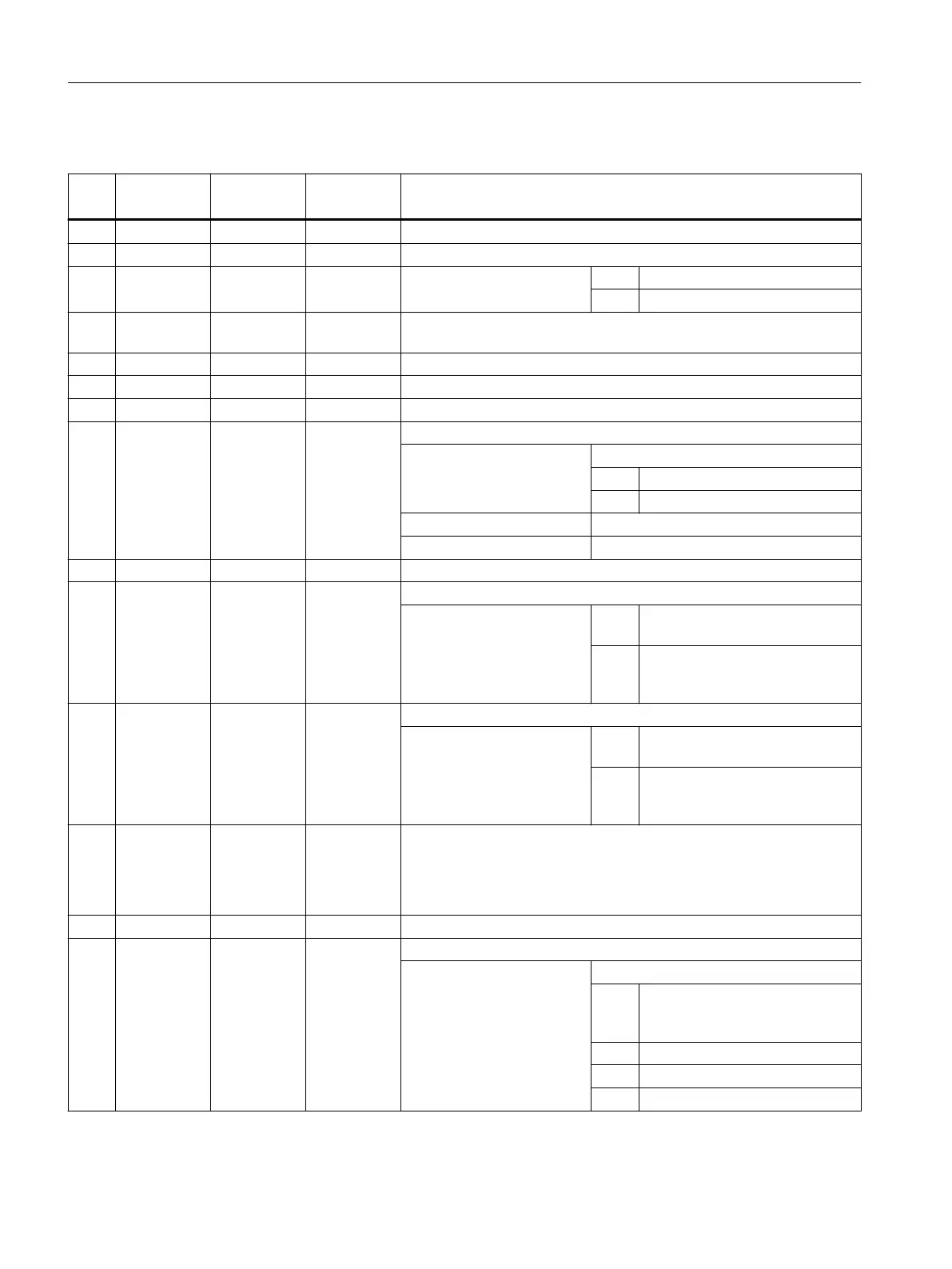

Parameters

No. Parameter

mask

Parameters

internal

Data type Meaning

1 X0 <_SPCA> REAL Reference point for position pattern (grid/frame) along the 1st axis (abs)

2 Y0 <_SPCO> REAL Reference point for position pattern (grid/frame) along the 2nd axis (abs)

3 α0 <_STA> REAL Basic angle of rotation

(angle to 1st axis)

< 0 = Clockwise rotation

> 0 = Counterclockwise rotation

4 L1 <_DIS1> REAL Distance between columns (position distance from the 1st axis, enter

without sign)

5 L2 <_DIS2> REAL Distance between rows (distance from the 2nd axis, enter without sign)

6 N1 <_NUM1> INT Number of columns

7 N2 <_NUM2> INT Number of rows

8 <_VARI> INT Machining type

UNITS: Position pattern

0 = Grid

1 = Frame

TENS: Reserved

HUNDREDS: Reserved

9 <_UMODE> INT Reserved

10 αX <_ANG1> REAL Shear angle to 1st axis (lines inclined in relation to the 1st axis)

< 0 = Clockwise measurement

(0 to -90 degrees)

> 0 = Counter-clockwise measure‐

ment

(0 to 90 degrees)

11 αY <_ANG2> REAL Shear angle to 2nd axis (columns inclined in relation to the 2nd axis)

< 0 = Clockwise measurement

(0 to -90 degrees)

> 0 = Counter-clockwise measure‐

ment

(0 to 90 degrees)

12 <_HIDE> STRING

[200]

Hidden positions

● Max. 198 characters

● Specification of consecutive position numbers, e.g. "1,3" (positions

1 and 3 are not executed)

13 <_NSP> INT Reserved

14 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

Work preparation

3.25 Programming cycles externally

NC programming

1098 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...