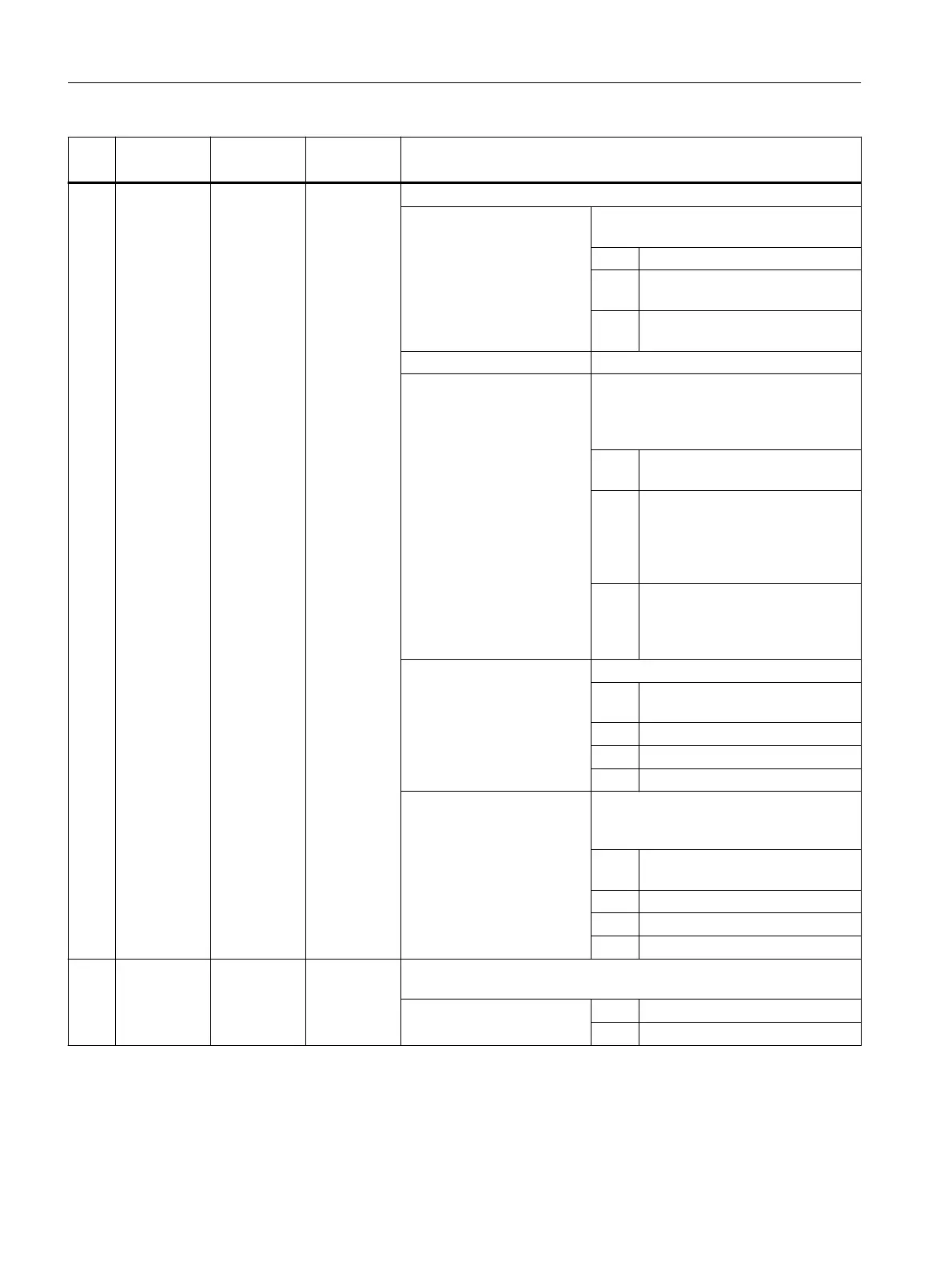

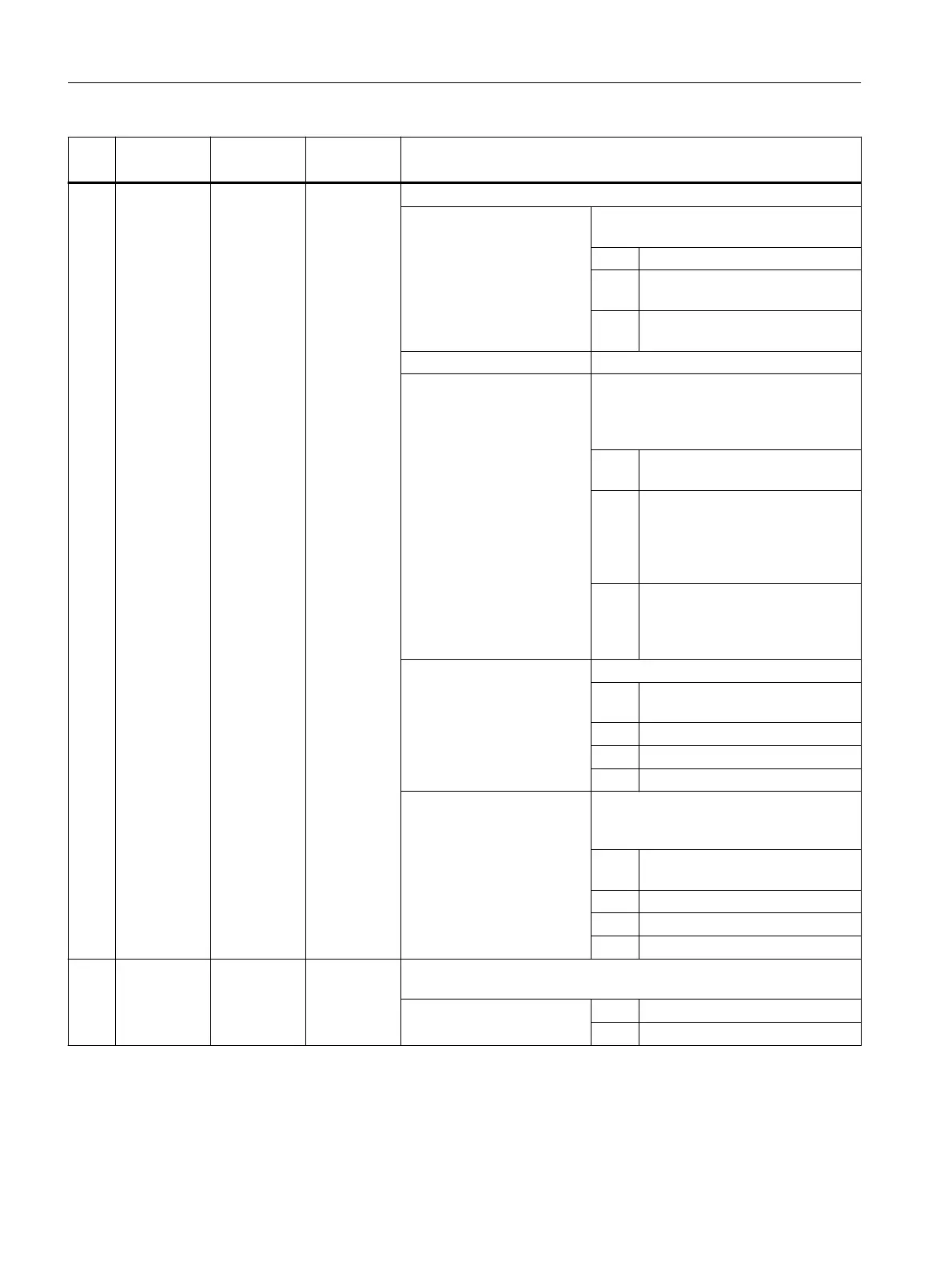

No. Parameter

mask

Parameters

internal

Data type Meaning

21 <_VARI> INT Machining

HUNDREDS: (Only for call from Jobshop) (At present

only 0 and 2 evaluated)

0 = Do not clamp spindle

1 = Only clamp spindle for vertical in‐

sertion with G00 or G01

2 = Clamp spindle during the entire

machining operation

THOUSANDS: Reserved

TEN THOUSANDS: Position pattern with/without rotary axis –

axis combination

(with <_VARI> HUNDRED THOU‐

SANDS)

0 = XY (only XY without rotary axis,

compatibility)

1 = X,Y or Z and rotary axis:

XA, YB, ZC

(1 rotary axis with geometry axis

around which the rotary axis ro‐

tates)

2 = XY and rotary axis:

XYA, XYB, XYC

(1 rotary axis with 1st and 2nd

geometry axis, without TRACYL)

HUNDRED THOUSANDS: Rotary axis

0 = Without rotary axis

(only XY, compatibility)

1 = A axis (rotary axis around X)

2 = B axis (rotary axis around Y)

3 = C axis (rotary axis around Z)

TEN MILLIONS + ONE MIL‐

LION:

Position pattern with rotary axis – offset

(for several rotary axes around the same

axis; if index too large, then 1st axis)

00 = 1st A, B or C axis or for compati‐

bility

01 = 2nd A, B or C axis

...

19 = 20th A, B or C axis

22 <_UMODE> INT Selection of the spindle to be clamped: (Only for call from Jobshop) (Call

of user cycle CUST_TECHCYC)

3 = Clamp/release main spindle

23 = Clamp/release counterspindle

Work preparation

3.25 Programming cycles externally

NC programming

1100 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...