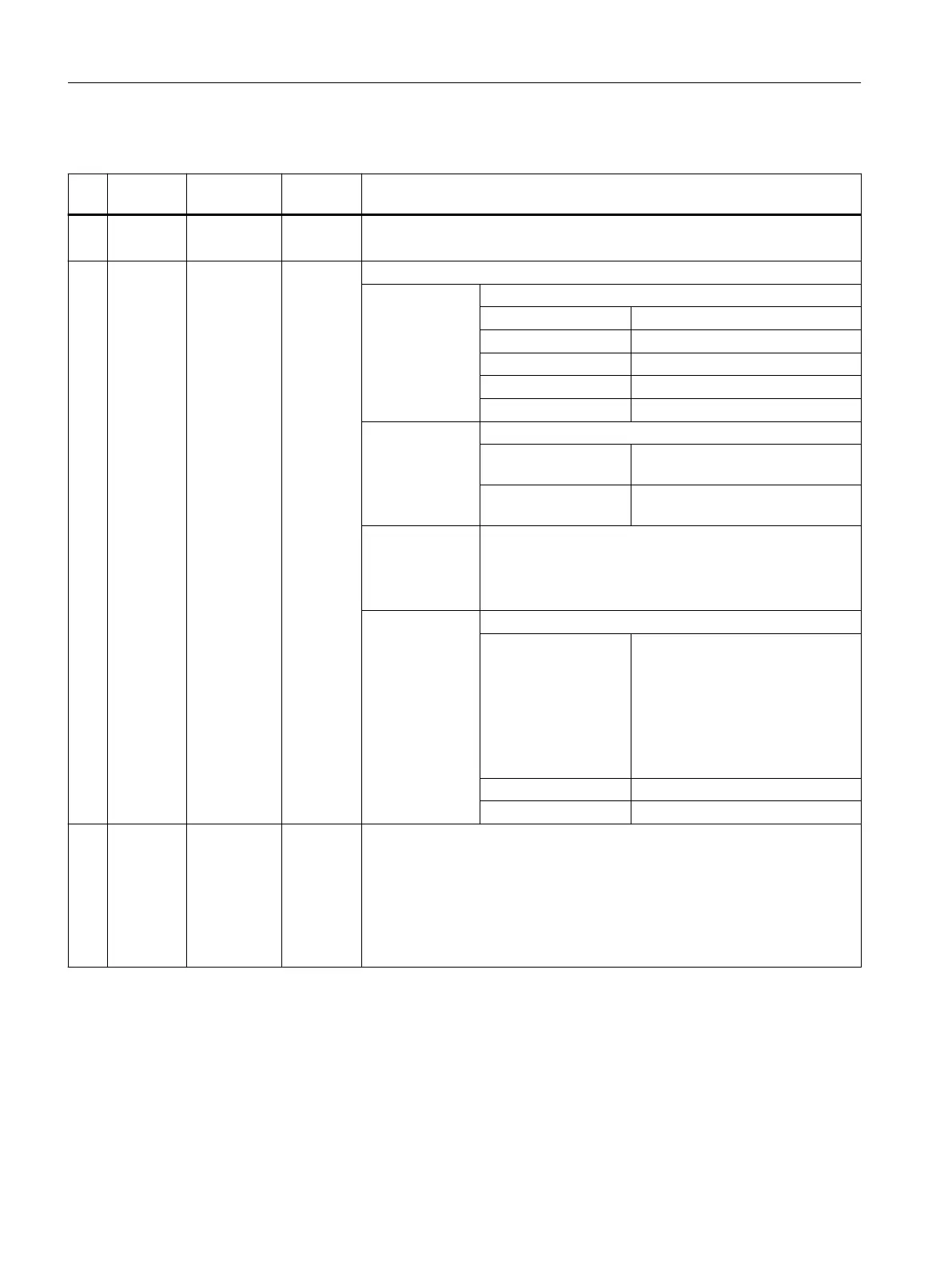

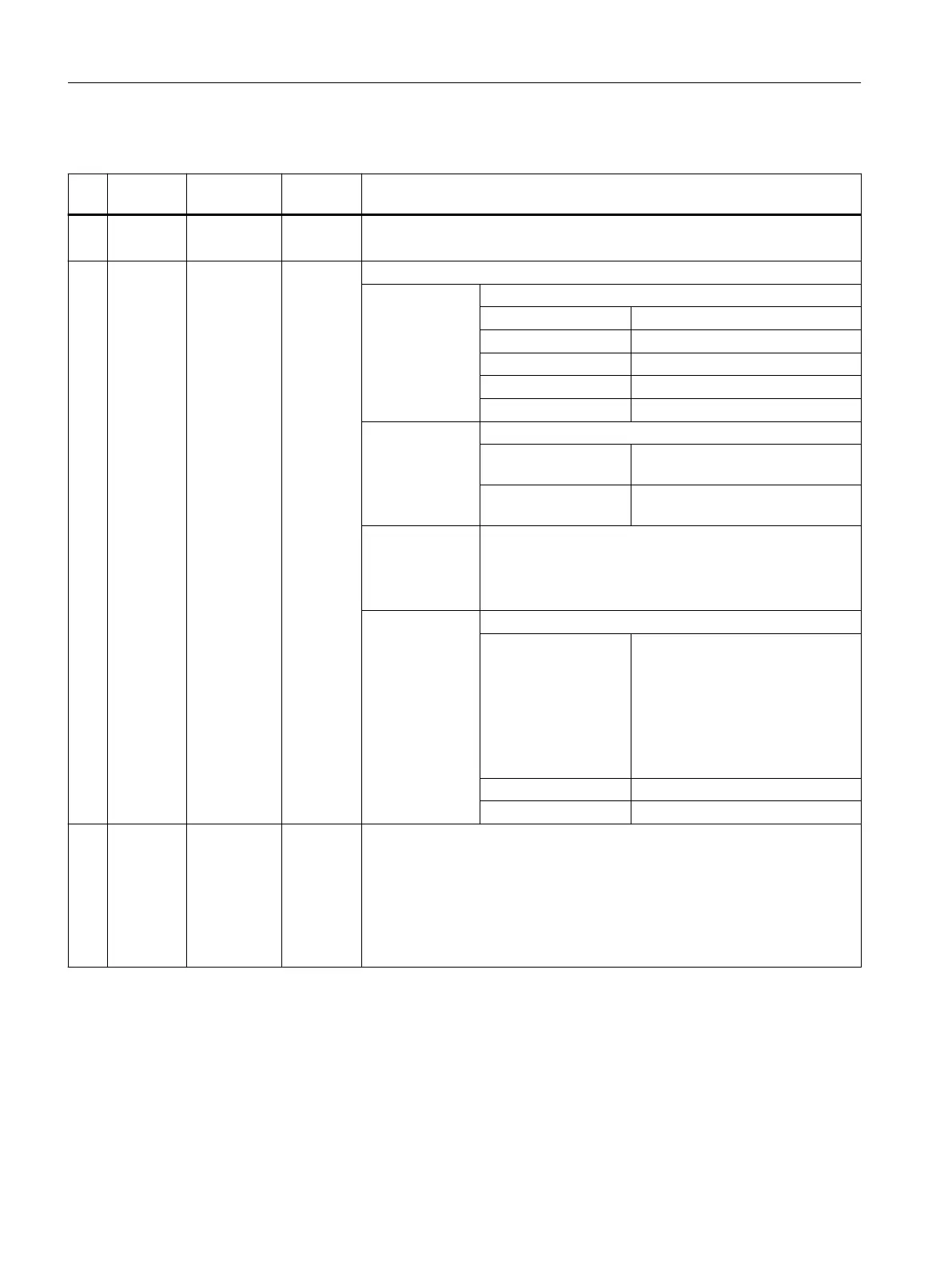

Parameters

No. Parame‐

ter mask

Parameter

internal

Data type Meaning

1 Tolerance <S_TOL> REAL Contour tolerance

The contour tolerance corresponds to the axis tolerance of the geometry axes.

2

<S_TOLM> INT Machining type (technology)

UNITS:

0 = Deselection

1 = Finishing

2 = Rough finishing (semi-finishing)

3 = Roughing

4 = Smooth finishing (precision)

TENS:

0 = Compatibility

1)

or no orientation tol‐

erance

1 = Orientation tolerance in parame‐

ter <S_OTOL>

HUNDREDS

...

HUNDRED

THOUSANDS

Assigned

for reasons of

compatibility

ONE MILLION:

0 = Compatibility. The best available

mold making function is automati‐

cally used:

● Option Top Surface not active:

Advanced Surface

● Option Top Surface active:

⇒ Top Surface with smoothing

1 = Top Surface without smoothing

2 = Top Surface with smoothing

3 ORI toler‐

ance

<S_OTOL> REAL Orientation tolerance or version identifier CYCLE832

Tolerance parameter for the orientation of the workpiece.

Is required when executing a high-speed machining program on machines

with dynamic orientation transformation (e.g. 5-axis machining).

Parameter <S_OTOL> must be programmed. This also applies for applications

on 3-axis machines for programs without orientation of the tool

(<S_OTOL> = 1).

1)

Orientation tolerance derived from the cycle setting data SD55451 ... SD55454 (orientation tolerance for dynamic response

mode...) or SD55445 ... SD55449 (contour tolerance for dynamic response mode...) multiplied by the factor from

SD55441 ... SD55444.

Further information: SINUMERIK Operate Commissioning Manual

Work preparation

3.25 Programming cycles externally

NC programming

1108 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...