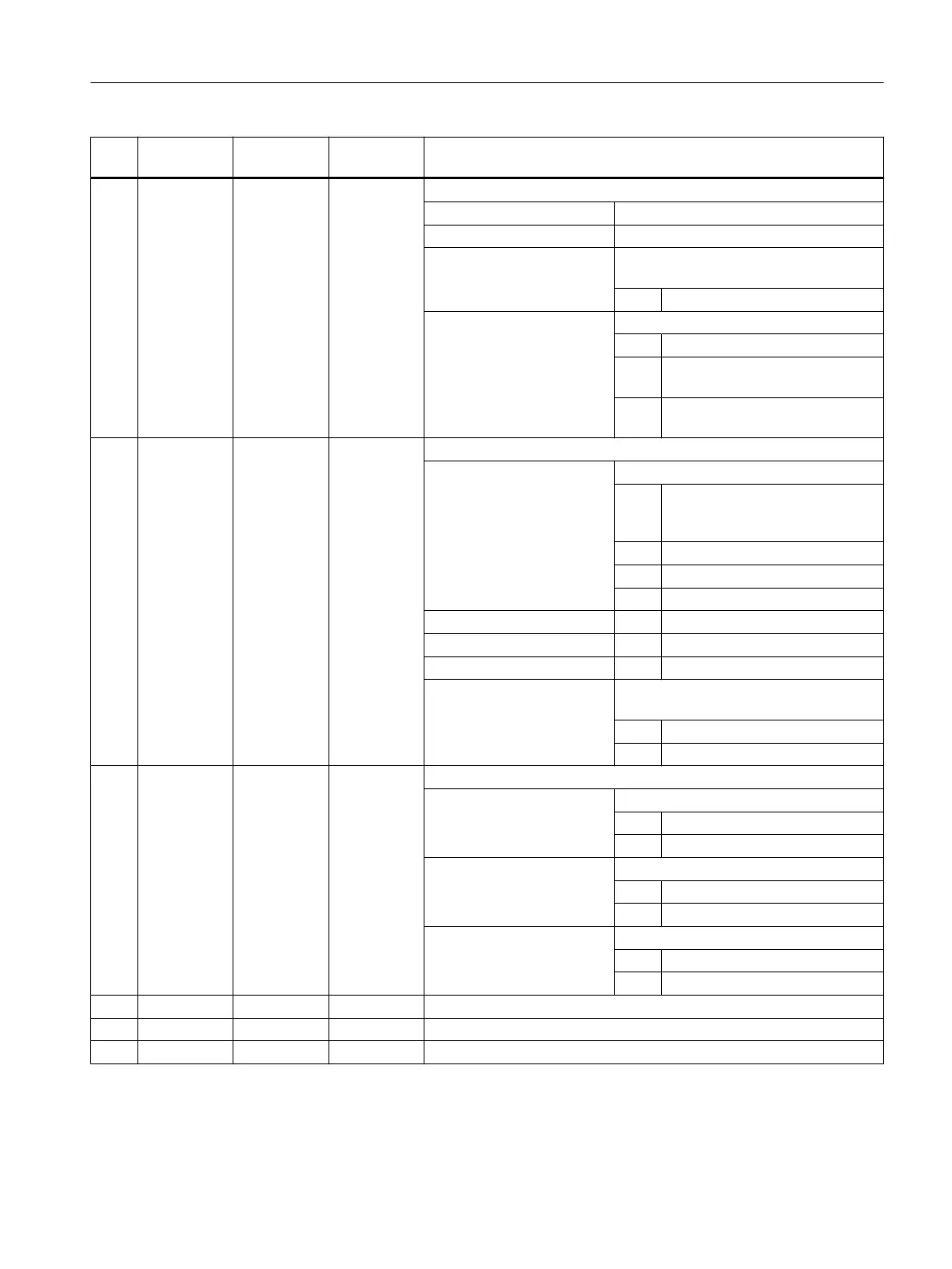

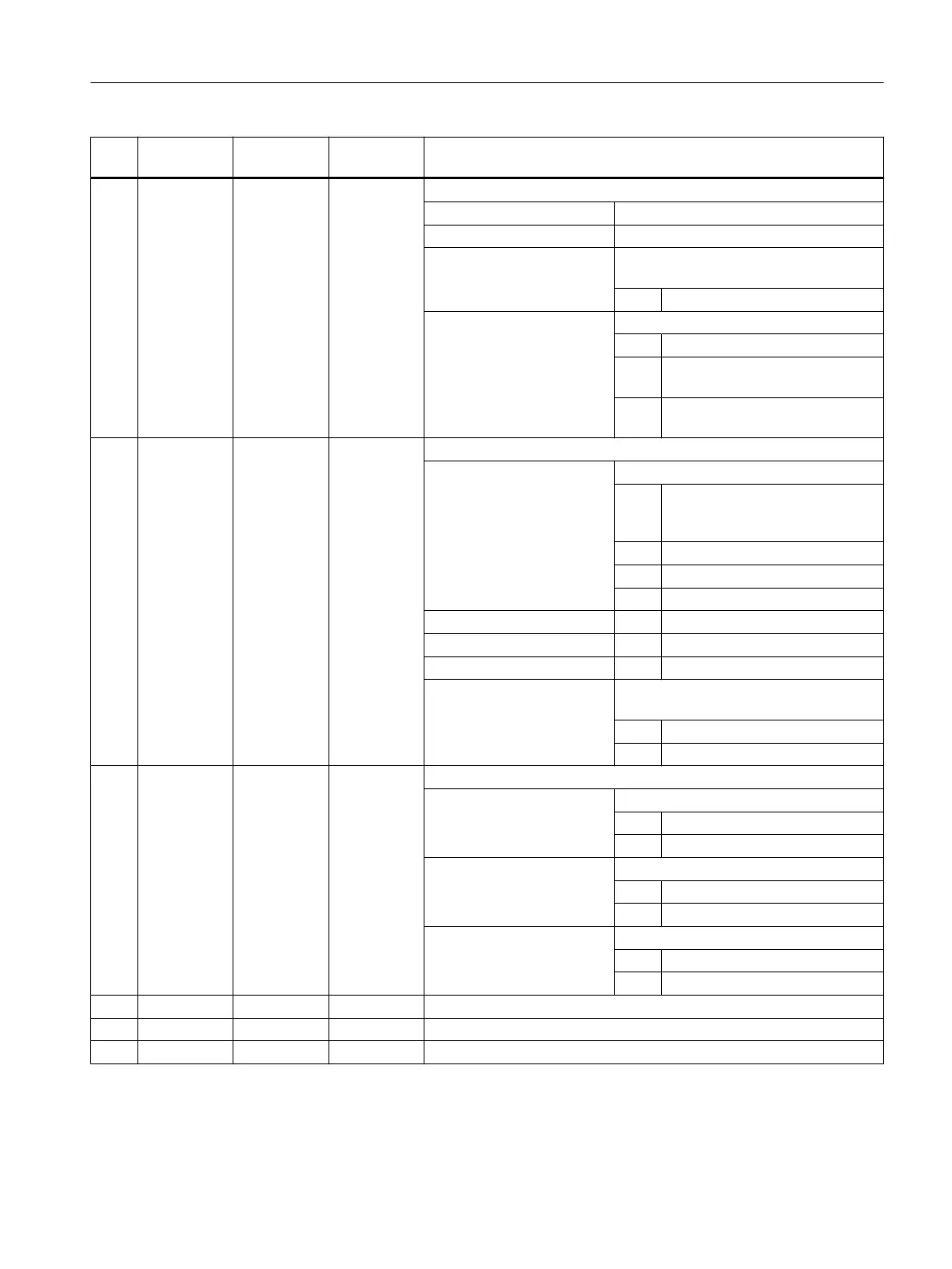

No. Parameter

mask

Parameter

internal

Data type Meaning

17 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Select machining/only calculation of start

point

1 = Normal machining

THOUSANDS: Dimensioning via center/edge

0 = Dimensioning via center

1 = "Left-hand" dimensioning using

edge ("-" direction of 1st axis)

2 = "Right-hand" dimensioning using

edge ("+" direction of 1st axis)

18 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

TENS: --- Reserved

HUNDREDS: --- Reserved

THOUSANDS: --- Reserved

TEN THOUSANDS: Technology scaling in cycle screen forms

(Page 1153)

0 = Input: Complete

1 = Input: Simple

19 <_AMODE> INT Alternative mode

UNITS: Slot depth Z1

0 = Absolute

1 = Incremental

TENS: Unit for plane infeed (<_MIDA>) DXY

0 = mm

1 = % of tool diameter

HUNDREDS: Insertion depth for chamfering ZFS

0 = Absolute

1 = Incremental

20 <_UMODE> INT Reserved

21 FS <_FS> REAL Chamfer width (inc)

22 ZFS <_ZFS> REAL Insertion depth (tool tip) on chamfering (abs/inc), see <_AMODE>

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1115

Loading...

Loading...