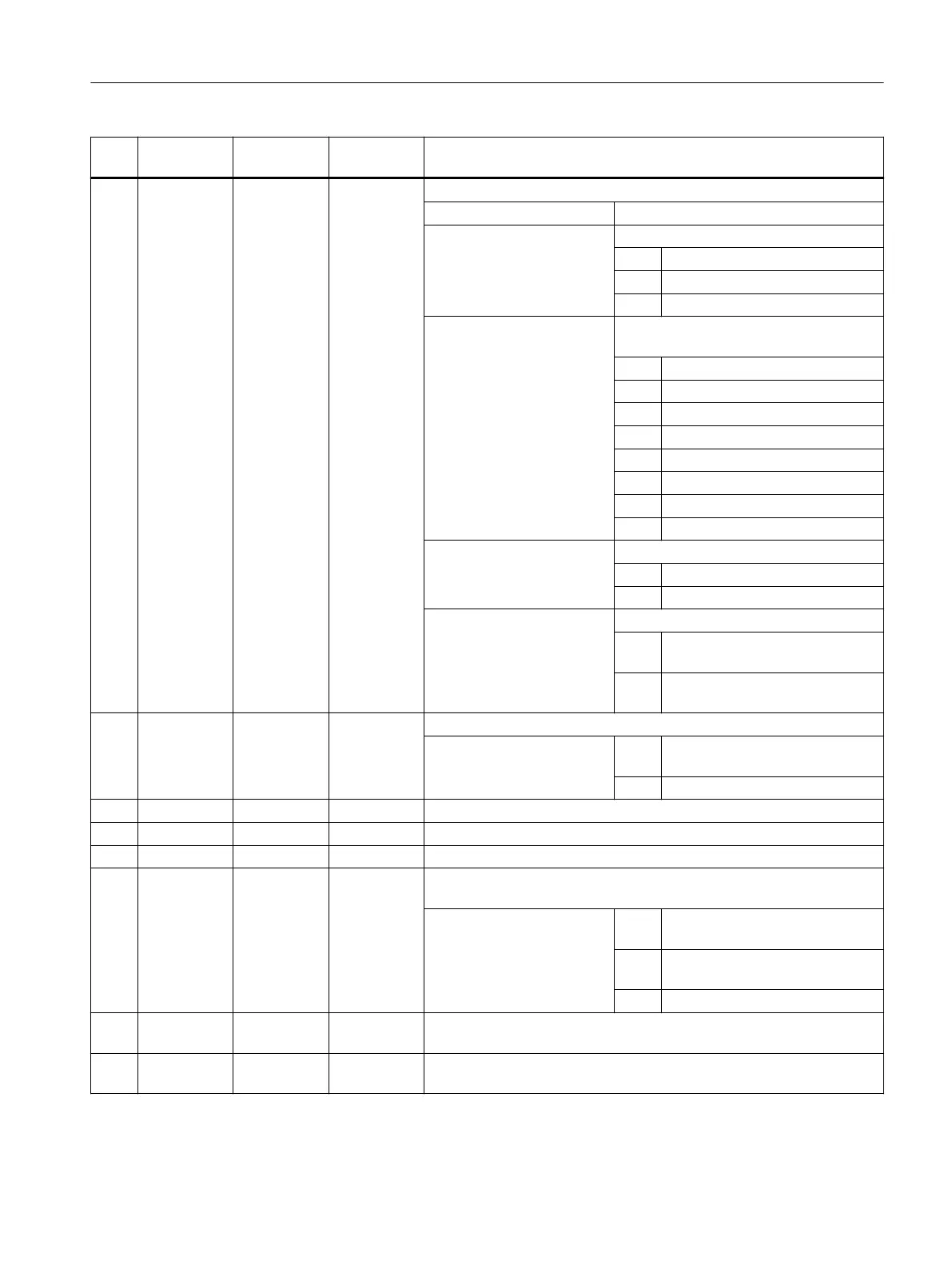

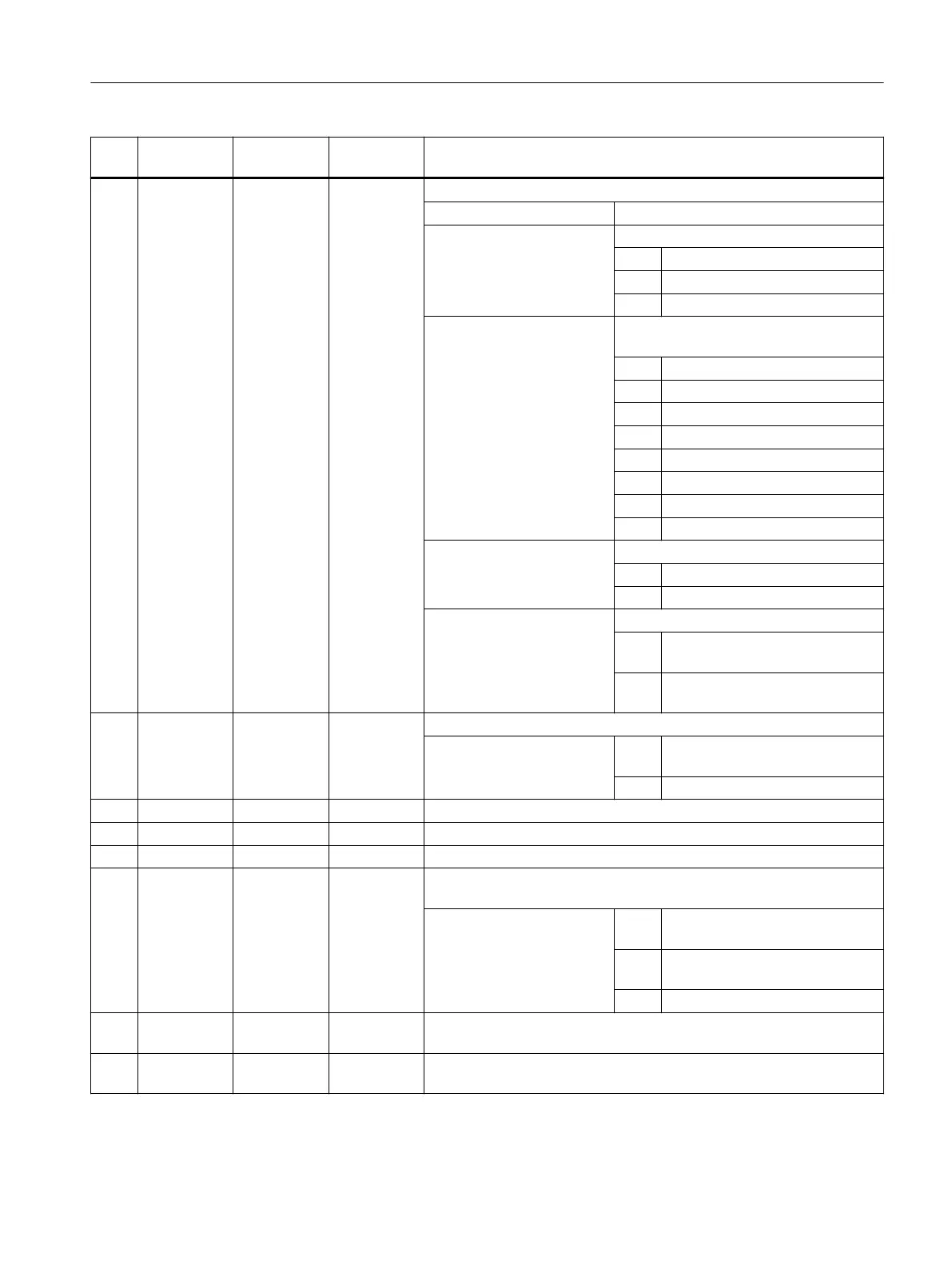

No. Parameter

mask

Parameter

internal

Data type Meaning

17 <_VARI> INT Machining type

UNITS: Reserved

TENS: Machining process

1 = Roughing

2 = Finishing

3 = Roughing and finishing

HUNDREDS: Position longitudinal/transverse external/

internal +Z/+Z and +X/-X

1 = Longitudinal/external +Z

2 = Transverse/internal -X

3 = Longitudinal/internal +Z

4 = Transverse/internal +X

5 = Longitudinal/external -Z

6 = Transverse/external -X

7 = Longitudinal/internal -Z

8 = Transverse/external +X

THOUSANDS: Position of reference point

0 = Upper reference point

1 = Lower reference point

TEN THOUSANDS: Define effect of finishing allowances

0 = Finishing allowance U parallel to

the contour

1 = Separate UX and UZ finishing al‐

lowances

18 <_DN> INT D number for 2nd edge of tool

> 0 = D number for tool offset of 2nd

edge of grooving tool

0 = No 2nd edge programmed

19 N <_NUM> INT Number of grooves (0 = 1 groove)

20 DP <_DBH> REAL Distance between grooves (only needed when <_NUM> > 1)

21 F <_FF1> REAL Feedrate

22 <_NR> INT Identification for form of groove corresponds to vertical softkey for form

selection

0 = 90° sides without chamfers/

rounding

1 = Inclined sides with chamfers/

rounding (without α0)

2 = As 1, but on taper (with α0)

23 UX <_FALX> REAL Finishing allowance in X axis, see <_VARI> (TEN THOUSANDS) (to be

entered without sign)

24 UZ <_FALZ> REAL Finishing allowance in Z axis, see <_VARI> (TEN THOUSANDS) (to be

entered without sign)

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1117

Loading...

Loading...