● A-D: DIN thread undercut (forms A-D)

● T: Thread undercut (free definition of form)

Syntax

CYCLE940(<_SPD>, <_SPL>, <_FORM>, <_LAGE>, <_SDIS>, <_FFP>, <_VARI>,

<_EPD>, <_EPL>, <_R1>, <_R2>, <_STA>, <_VRT>, <_MID>, <_FAL>,

<_FALX>, <_FALZ>, <_PITI>, <_PTAB>, <_PTABA>, <_DMODE>, <_AMODE>)

Parameters

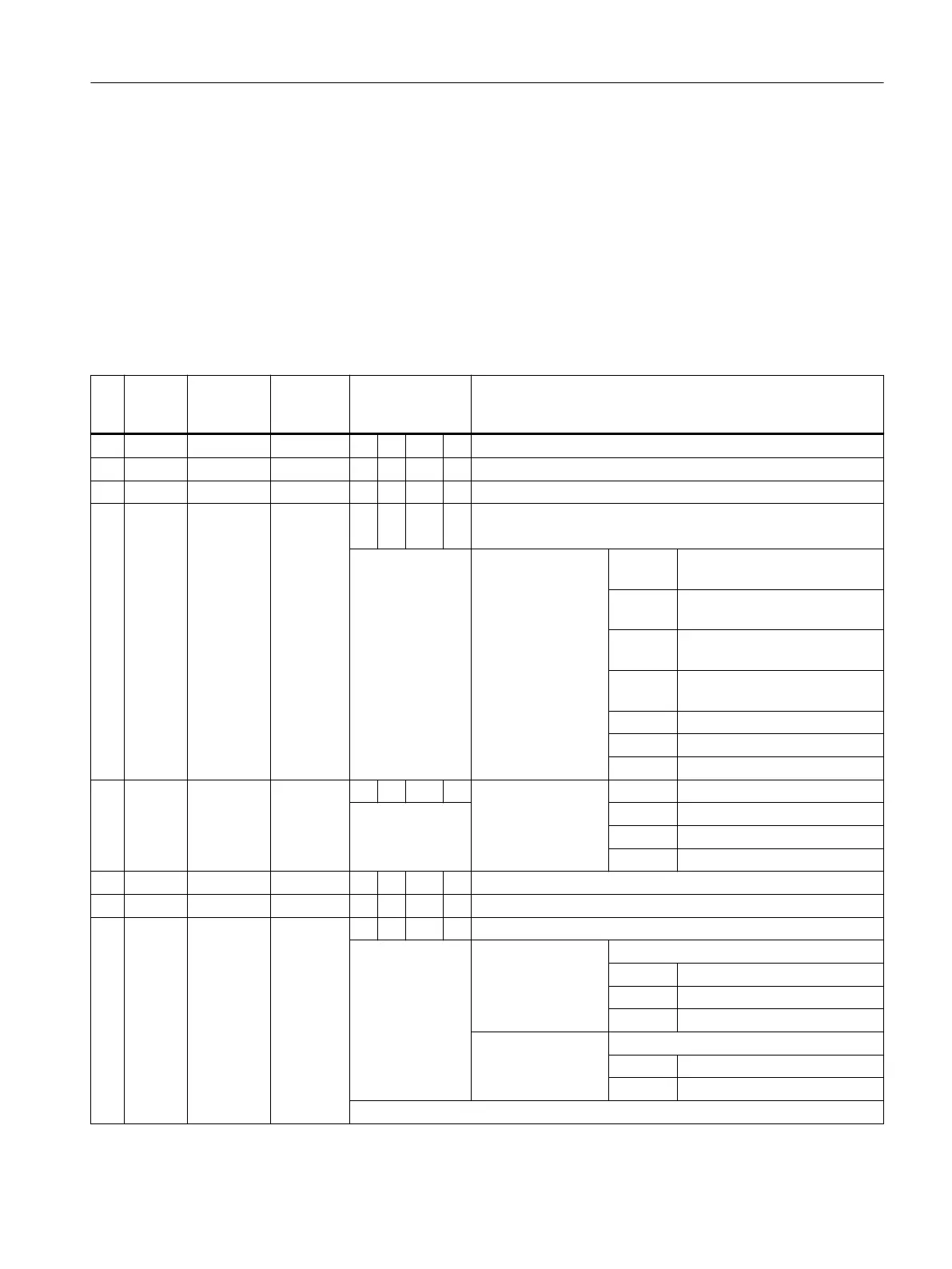

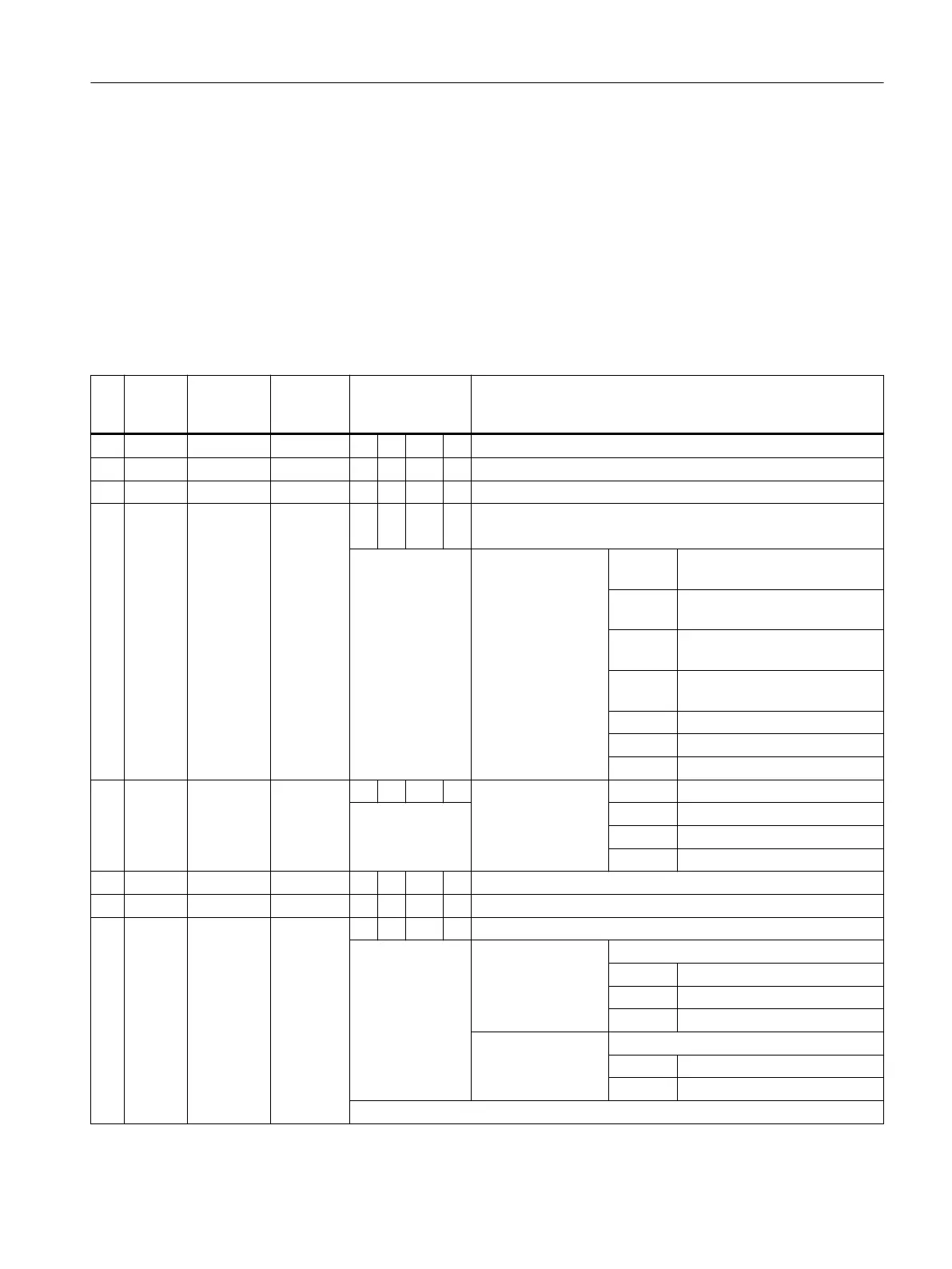

No

.

Param‐

eter

mask

Parameter

internal

Data type Prog. for form Meaning

E F A-D T

1 X0 <_SPD> REAL x x x x Reference point in the plane axis (always diameter)

2 Z0 <_SPL> REAL x x x x Reference point on longitudinal axis (abs)

3 FORM <_FORM> CHAR x x x x Form of undercut (capital letters, e.g. "T")

Selection, table from which the undercut values should be taken

A = External, reference DIN76,

A = normal

B = External, reference DIN76,

B = short

C = Internal, reference DIN76,

C = normal

D = Internal, reference DIN76,

D = short

E = Reference DIN509

F = Reference DIN509

T= Free-form

4 POSI‐

TION

<_LAGE> INT x x x x Position of under‐

cut (parallel Z)

0 = External +Z: \____|

1 = External -Z: |____/

2 = Internal +Z: /-----|

3 = Internal -Z: |-----\

5 SC <_SDIS> x x x x Safety clearance (inc)

6 F <_FFP> x x x x Machining feedrate (mm/rev)

7 <_VARI> INT - - x x Machining type

UNITS: Machining

1 = Roughing

2 = Finishing

3 = Roughing + finishing

TENS: Machining strategy

0 = Parallel to the contour

1 = Longitudinal

Undercut forms E and F are always machined in a single pass like finishing.

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1119

Loading...

Loading...