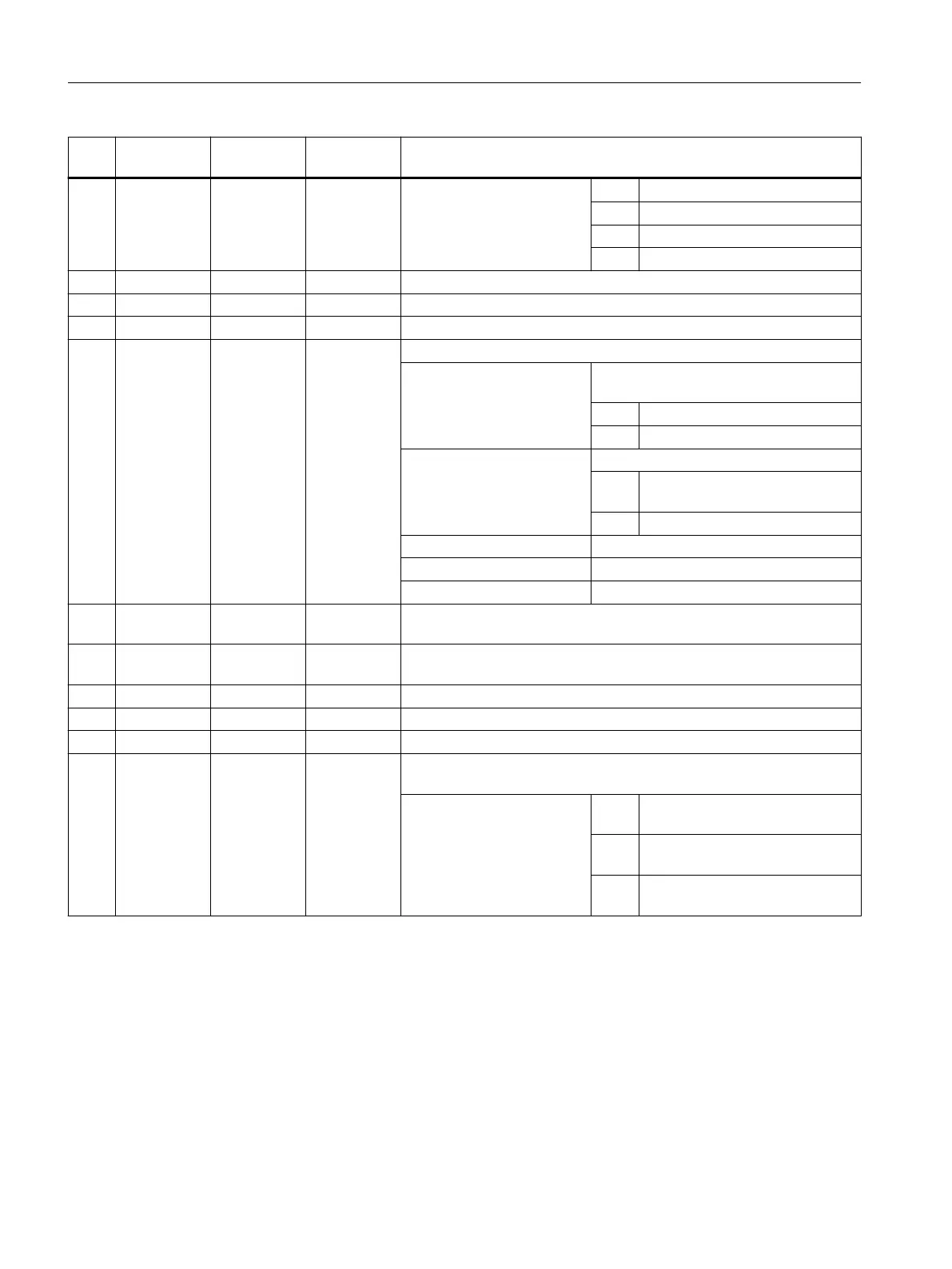

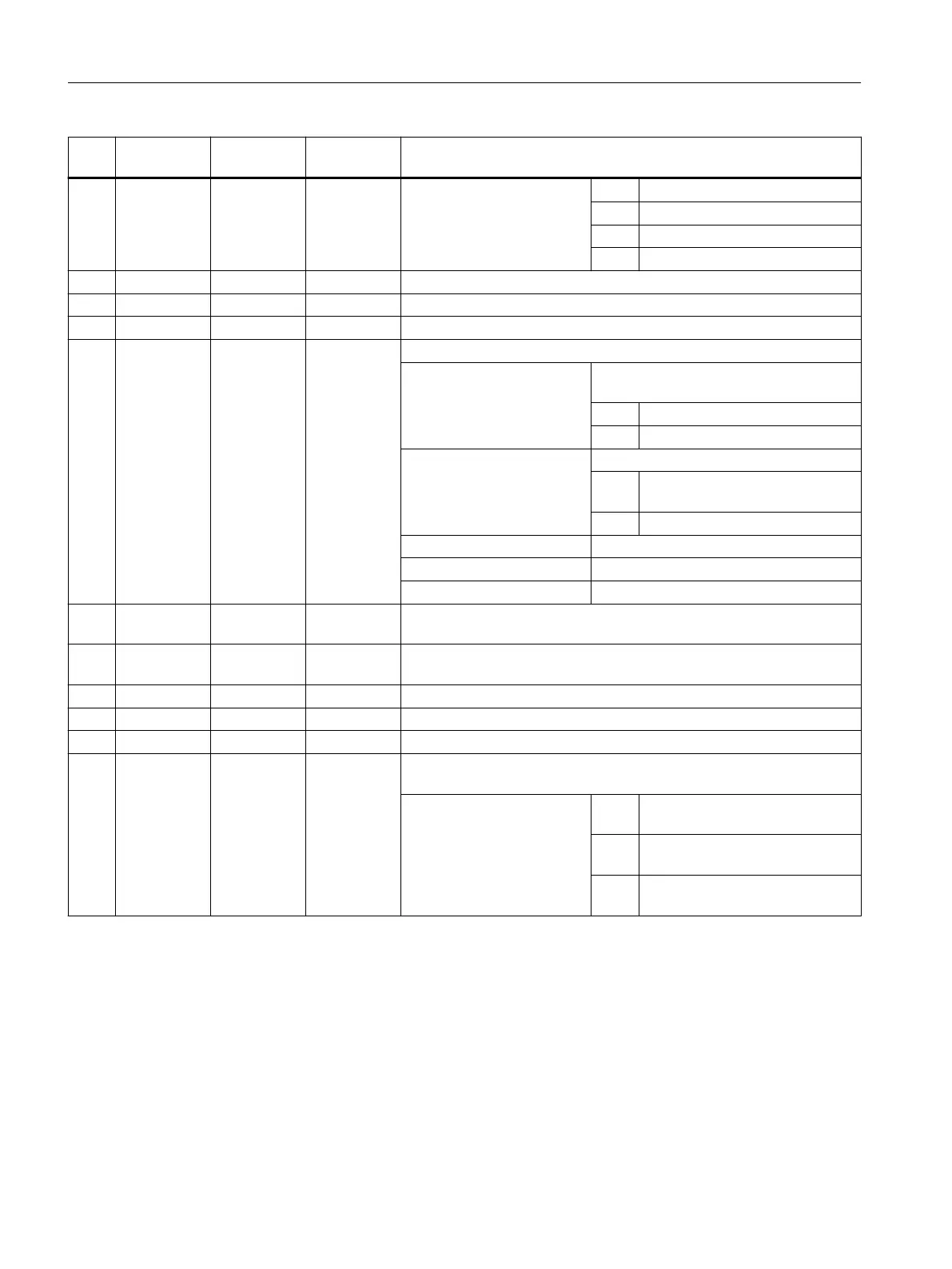

No. Parameter

mask

Parameter

internal

Data type Meaning

7 Position <_LAGE> INT Position of stock removal

corner

0 = External/rear

1 = External/front

2 = Internal/rear

3 = Internal/front

8 D <_MID> REAL Maximum depth infeed on insertion

9 UX <_FALX> REAL Finishing allowance in X

10 UZ <_FALZ> REAL Finishing allowance in Z

11 <_VARI> INT Machining type

UNITS: Stock removal direction (longitudinal or

transverse) in the coordinate system

1 = Longitudinal

2 = Face

TENS:

1 = Roughing to final machining al‐

lowance

2 = Finishing

HUNDREDS: Reserved

THOUSANDS: Reserved

TEN THOUSANDS: Reserved

12 R1/FS1 <_RF1> REAL Rounding radius or chamfer width 1, see <_AMODE> (TEN THOU‐

SANDS)

13 R2/FS2 <_RF2> REAL Rounding radius or chamfer width 2, see <_AMODE> (HUNDRED

THOUSANDS)

14 R3/FS3 <_RF3> REAL Rounding radius or chamfer width 3, see <_AMODE> (ONE MILLION)

15 SC <_SDIS> REAL Safety clearance

16 F <_FF1> REAL Feedrate for roughing/finishing

17 <_NR> INT Identification of stock removal type (corresponds to vertical softkey for

selecting form):

0 = Stock removal 1, 90 degree cor‐

ner without chamfers/rounding

1 = Stock removal 2, 90 degree cor‐

ner with chamfers/rounding

2 = Stock removal 3, any corner with

chamfers/rounding

Work preparation

3.25 Programming cycles externally

NC programming

1122 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...