Cancellation of the infeed at the start

6B$!

6B%!

6B:!

) 6B.!

) 6B,!

6B8!

6B8!

6B8!

6B*$8*(!

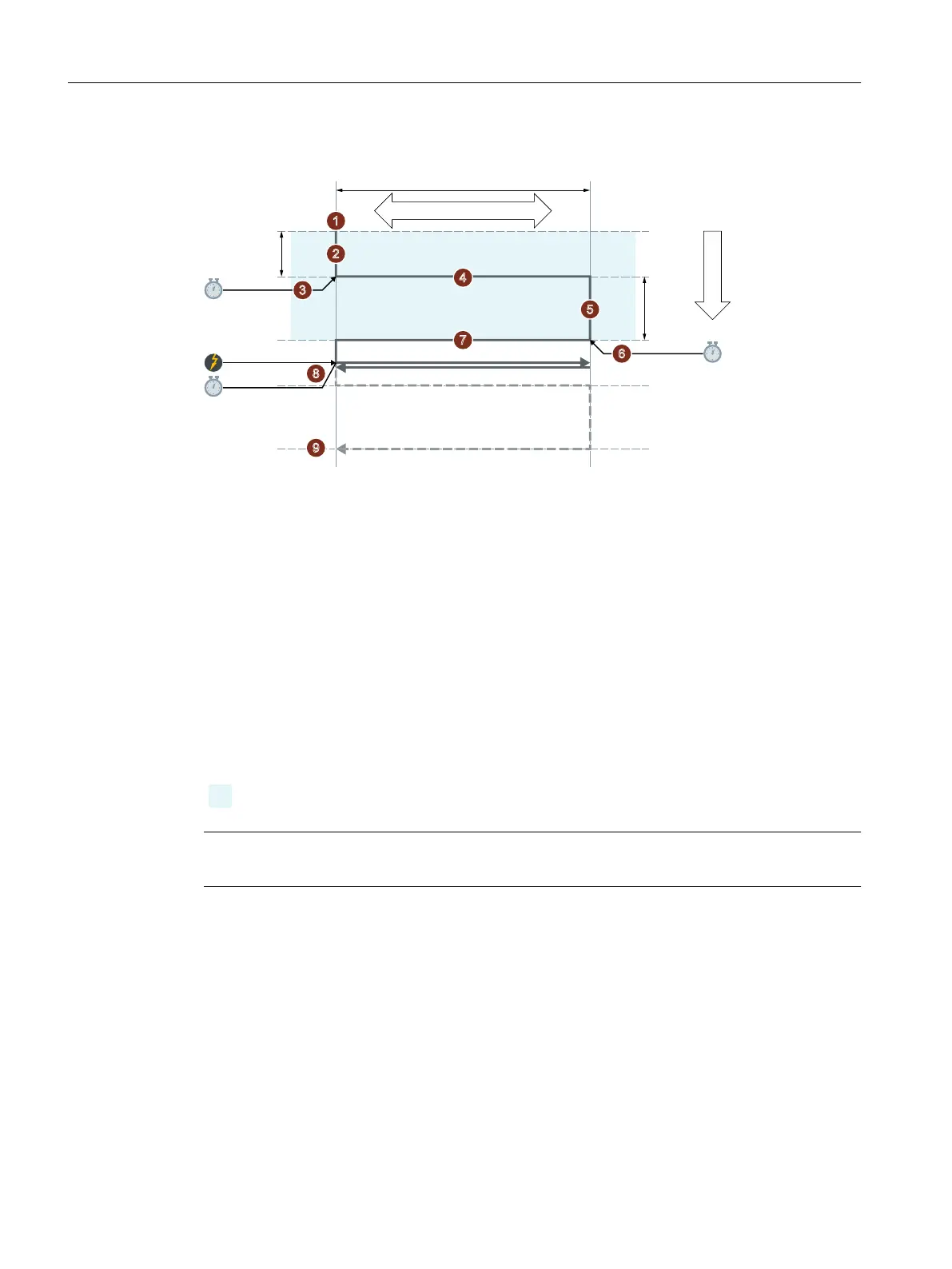

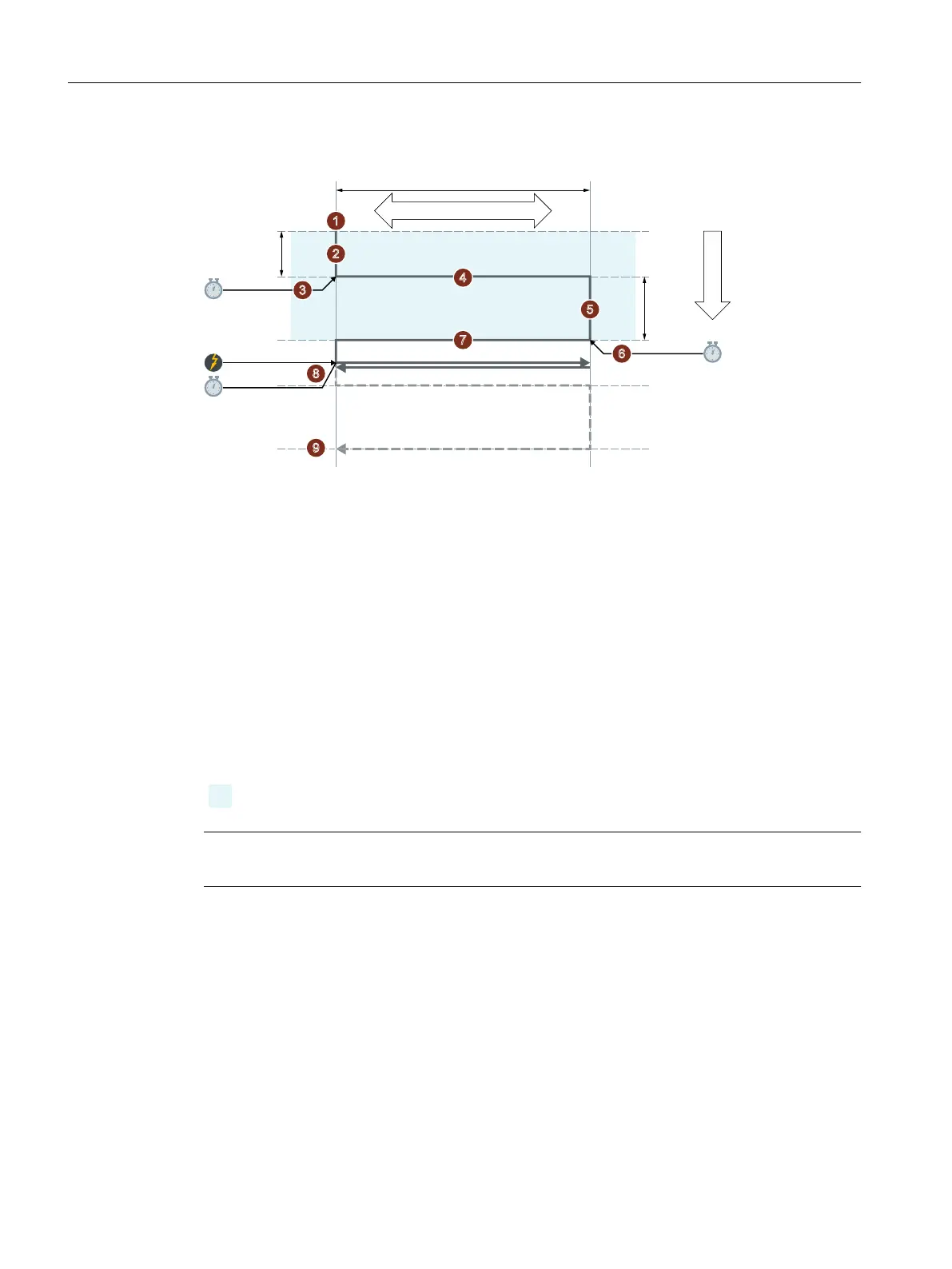

① Start of the cycle at the current position of the oscillating axis.

② Traversing of the infeed axis to the infeed depth at the start <S_A> with the feedrate for in‐

feed <S_I>.

③ Sparking out with the sparking-out time <S_U>.

④ Traversing of the oscillating axis with the grinding width <S_W> as travel path and the feedrate

for transverse infeed <S_K>.

⑤ Traversing of the infeed axis to the infeed depth at the end <S_B> with the feedrate for

infeed <S_I>.

⑥ Sparking out with the sparking-out time <S_U>.

⑦ Traversing of the oscillating axis with the grinding width <S_W> as travel path to the starting point

and the feedrate for transverse infeed <S_K>.

⑧ Cancel signal: The machining stops when the next start point is reached.

⑨ Without Cancel signal: The sequence is repeated until the programmed number of

repetitions <S_H> has been reached.

Indicates reiterating sequential steps.

Note

The sequence cannot be interrupted with a single block.

Resources

As resources, the cycle uses a block-wide synchronized action and a synchronized action

variable. The synchronized action is determined dynamically from the free area of the

synchronized action range (CUS.DIR - 1 ..., CMA.DIR - 1000 ..., CST.DIR – 1199 ...).

SYG_IS[1] is used as the synchronized action variable.

Work preparation

3.25 Programming cycles externally

NC programming

1134 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...