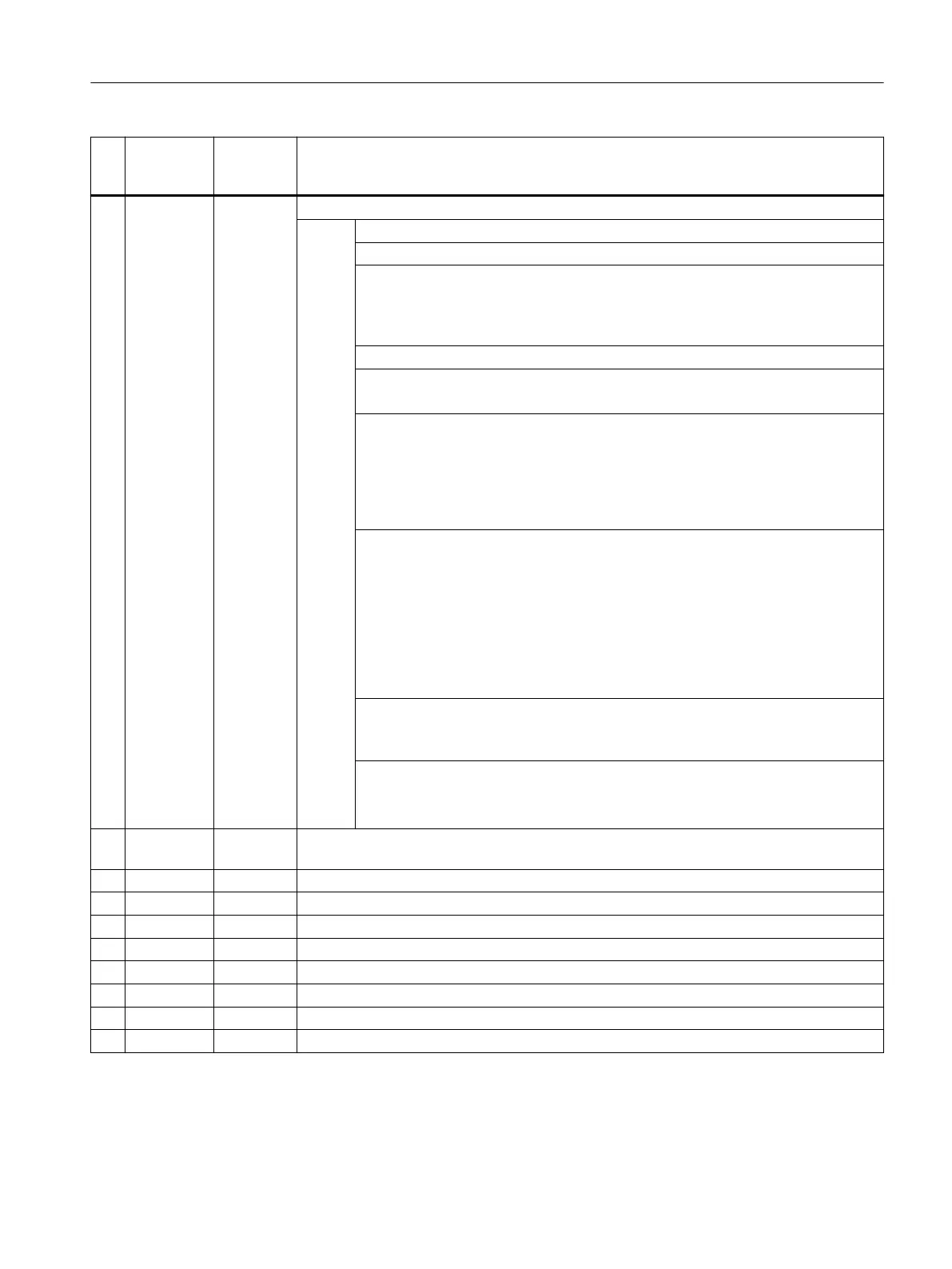

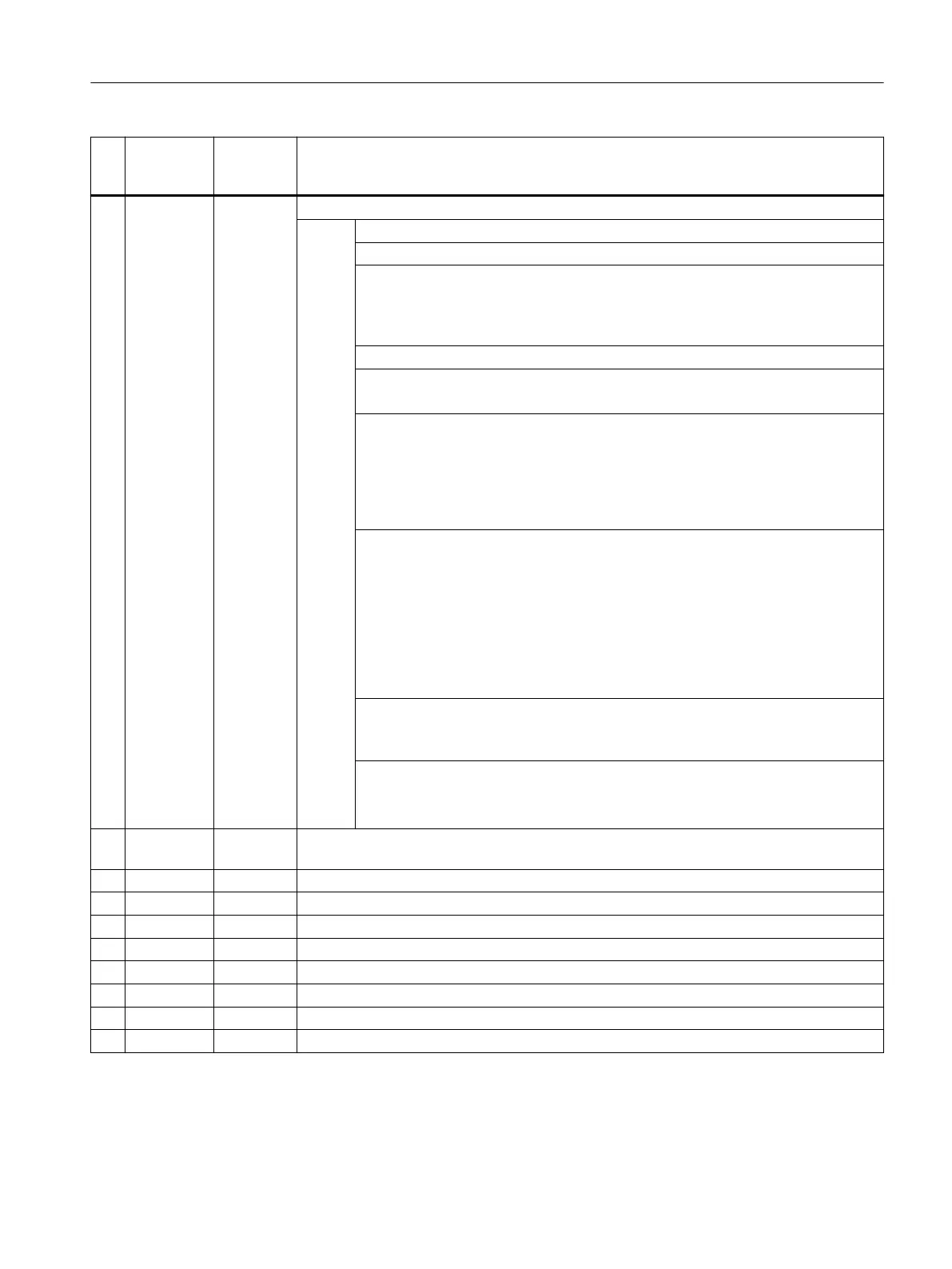

No. Screen

form param‐

eter

Cycle pa‐

rameter

Meaning

3 Selection S_KNUM1 Correction in tool offset

2)

Val‐

ues:

UNITS:

TENS:

HUNDREDS:

0 = No correction

1 to max. 999 D numbers (cutting edge numbers) for tool offset; for additive and

setup offset, see also S_DLNUM

THOUSANDS: 0 or unique D numbers

TEN THOUSANDS: 0 or unique D numbers

1 to max. 32000 if unique D numbers in MDs have been set up

HUNDRED THOUSANDS: Tool offset

2)

0 = No specification (offset tool radius)

1 = Offset of length L1

2 = Offset of length L2

3 = Offset of length L3

4 = Radius offset

ONE MILLION: Tool offset

2)

0 = No specification (offset of the tool radius wear)

1 = Tool offset, additive offset (AO)

5)

Tool offset value is added to the existing AO

2 = Tool offset, setup offset (SO)

5)

SO (new) = SO (old) + AO (old) offset value, AO (new) = 0

3 = Tool offset, setup offset (SO)

5)

Tool offset value is added to the existing SO

4 = Tool offset, geometry

TEN MILLION: Tool offset

2)

0 = No specification (offset in tool geometry normal, not inverted)

1 = Offset inverted

HUNDRED MILLIONS: Tool offset

0 = Tool offset without replacement tools

1 = Tool offset in replacement tool (_DP)

4 Icon+

number

S_PRNUM Number of the field of the probe parameters (not probe number)

(value range 1 to 40)

5 X0 S_SETV Setpoint

6 X0 S_SETV0 Setpoint for rectangle in 1st axis of the plane (X for G17)

7 Y0 S_SETV1 Setpoint for rectangle in 2nd axis of the plane (Y for G17)

8 XM S_XM Setpoint center point input geometry axis X

9 YM S_YM Setpoint center point input geometry axis Y

10 DFA S_FA Measurement path

11 TSA S_TSA Safe area

12 α 0 S_STA1 Starting angle

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1173

Loading...

Loading...