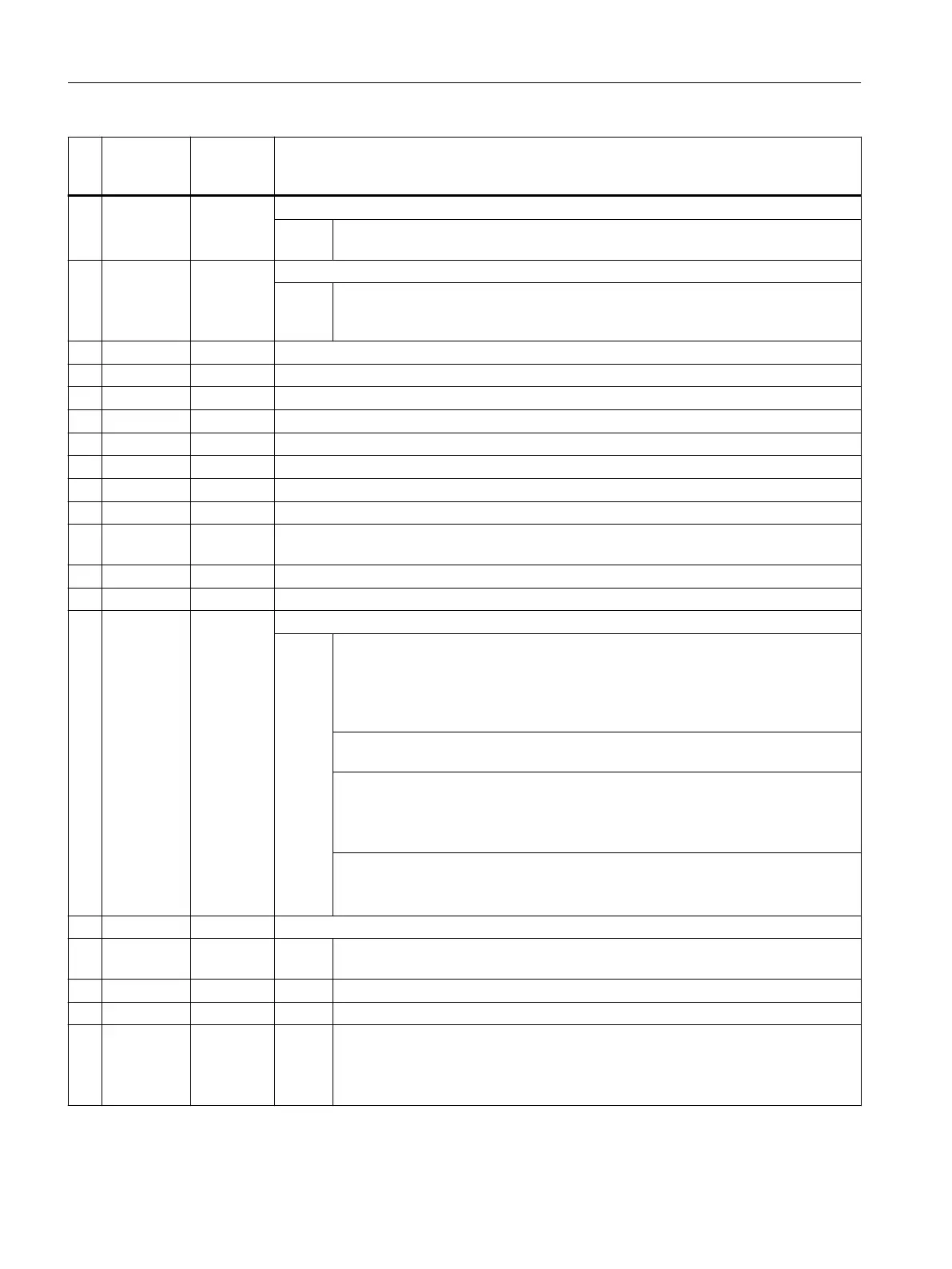

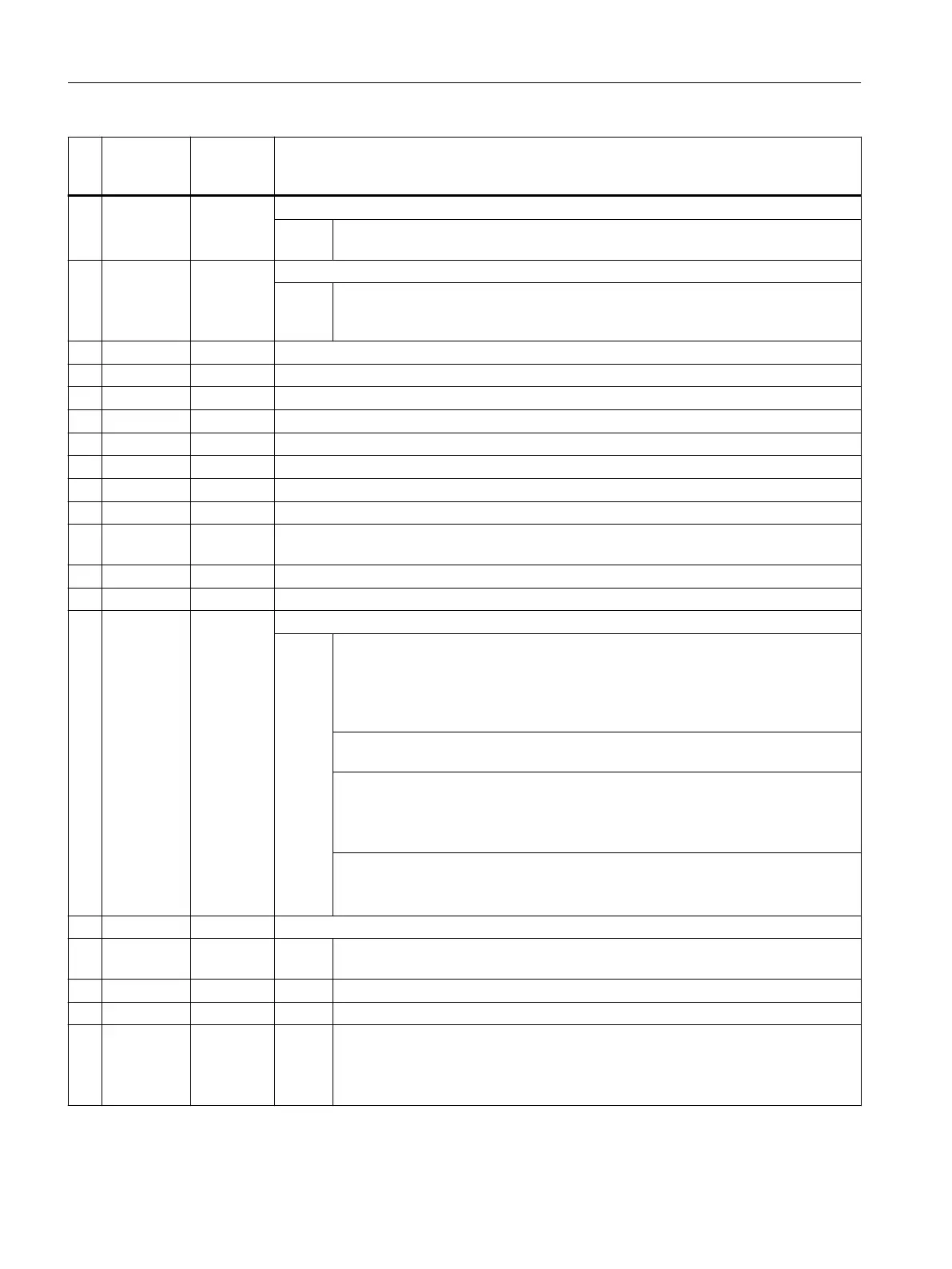

No. Screen

form param‐

eter

Cycle pa‐

rameter

Meaning

4 X0 S_MA Measuring axis

Val‐

ues:

1 = 1st axis of the plane (for G18 Z)

2 = 2nd axis of the plane (for G18 X)

5 +- S_MD Measuring direction

Val‐

ues:

0 = No selection (measuring direction is determined from actual value)

1 = Positive

2 = Negative

6 Z2 S_ID Offset

7 DFA S_FA Measurement path

8 TSA S_TSA Safe area

9 VMS S_VMS Variable measuring velocity for calibration

2)

10 alpha1 S_STA1 Starting angle when measuring milling tools

11 alpha2 S_CORA Offset angle when measuring milling tools with reversal

8)

12 TZL S_TZL Work offset when measuring milling tools. When calibrating S_TZL = 0

13 DIF S_TDIF Dimensional difference check

14 Measure‐

ments

S_NMSP Number of measurements at the same location

2)

(default=1)

15 EVN S_EVNUM Number of the empirical mean value memory

2), 9)

16 S_MCBIT Reserved

17 _DMODE Display mode

Val‐

ues:

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane active before the cycle call remains active

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

TENS: Cutting edge position for turning and milling tools

(only for display in the input screens 1 to 9)

HUNDREDS: Tool type

0 = Turning tool

1 = Milling tool

2 = Drill

THOUSANDS: The approach strategy with reference to the tool probe

0 = PLUS [X/Z]; X if tool position axial, Z if tool position radial

1 = MINUS [X/Z]; X if tool position axial, Z if tool position radial

18 _AMODE Alternative mode

Val‐

ues:

UNITS: Reserved

TENS: Reserved

HUNDREDS: Reserved

THOUSANDS: approach starting position after measurement for calibration and

single measurement (see S_MVAR - UNITS)

0 = Tool is located, offset by DFA with respect to the probe edge

1 = Approach starting position

1)

All default values = 0 or marked as default=x

Work preparation

3.25 Programming cycles externally

NC programming

1190 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...