Program code Comment

N105 G96 S210 M3 ; Select constant cutting rate.

N110 G0 G42 X50 Z-60 M8 ; Set tool with tool radius compensation.

N115 G1 Z-70 F0.12 ; Turn diameter 50.

N120 G2 X50 Z-80 I6.245 K-5 ; Turn radius 8.

N125 G0 G40 X100 Z50 M9 ; Retract tool and deselect tool radius

compensation.

N130 G0 G53 X280 Z380 D0 M5 ; Approach tool change location.

N135 M30 ; End of program.

Further information

The control requires the following information in order to calculate the tool paths:

● Tool no. (T...), cutting edge no. (D...)

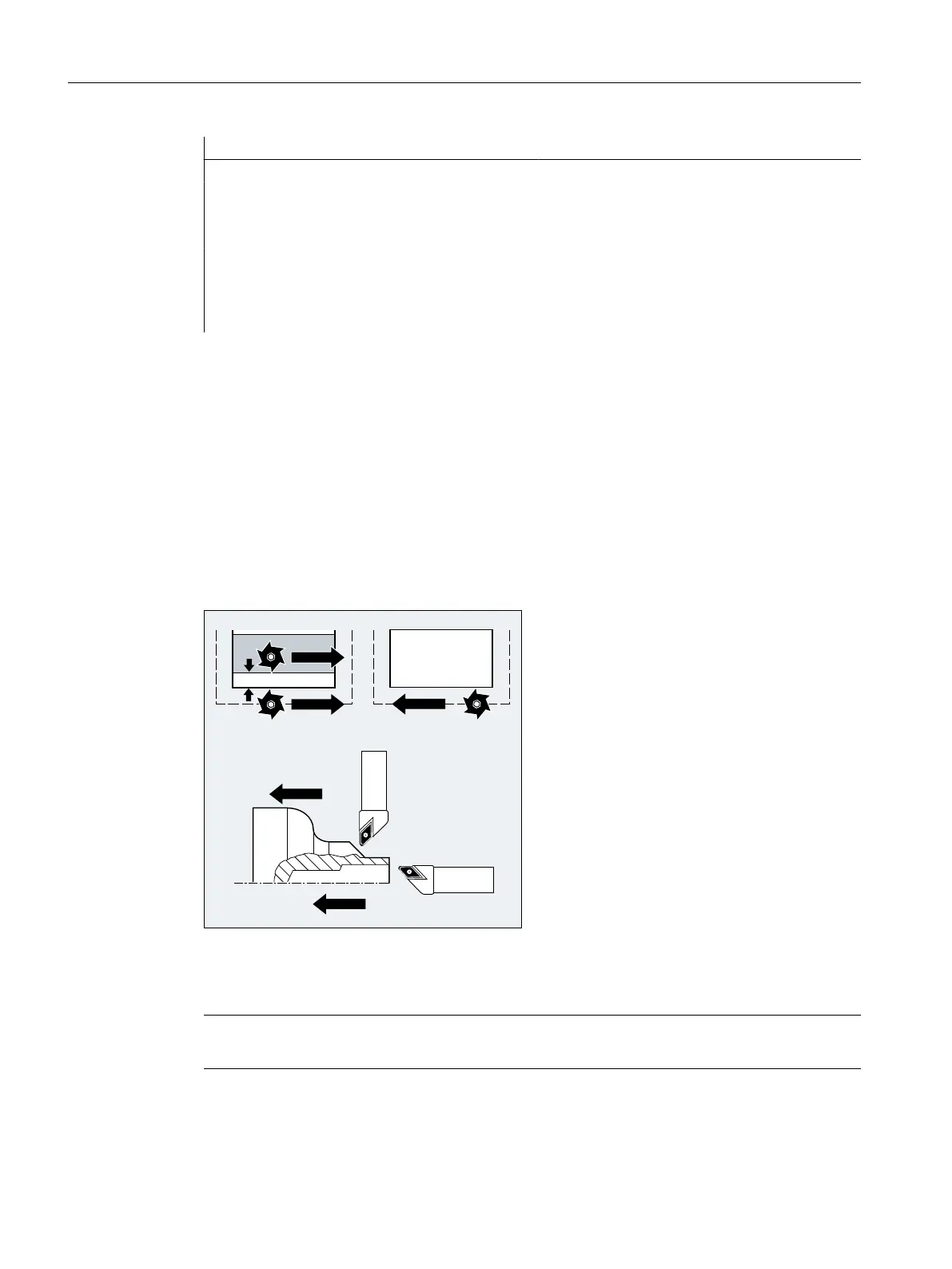

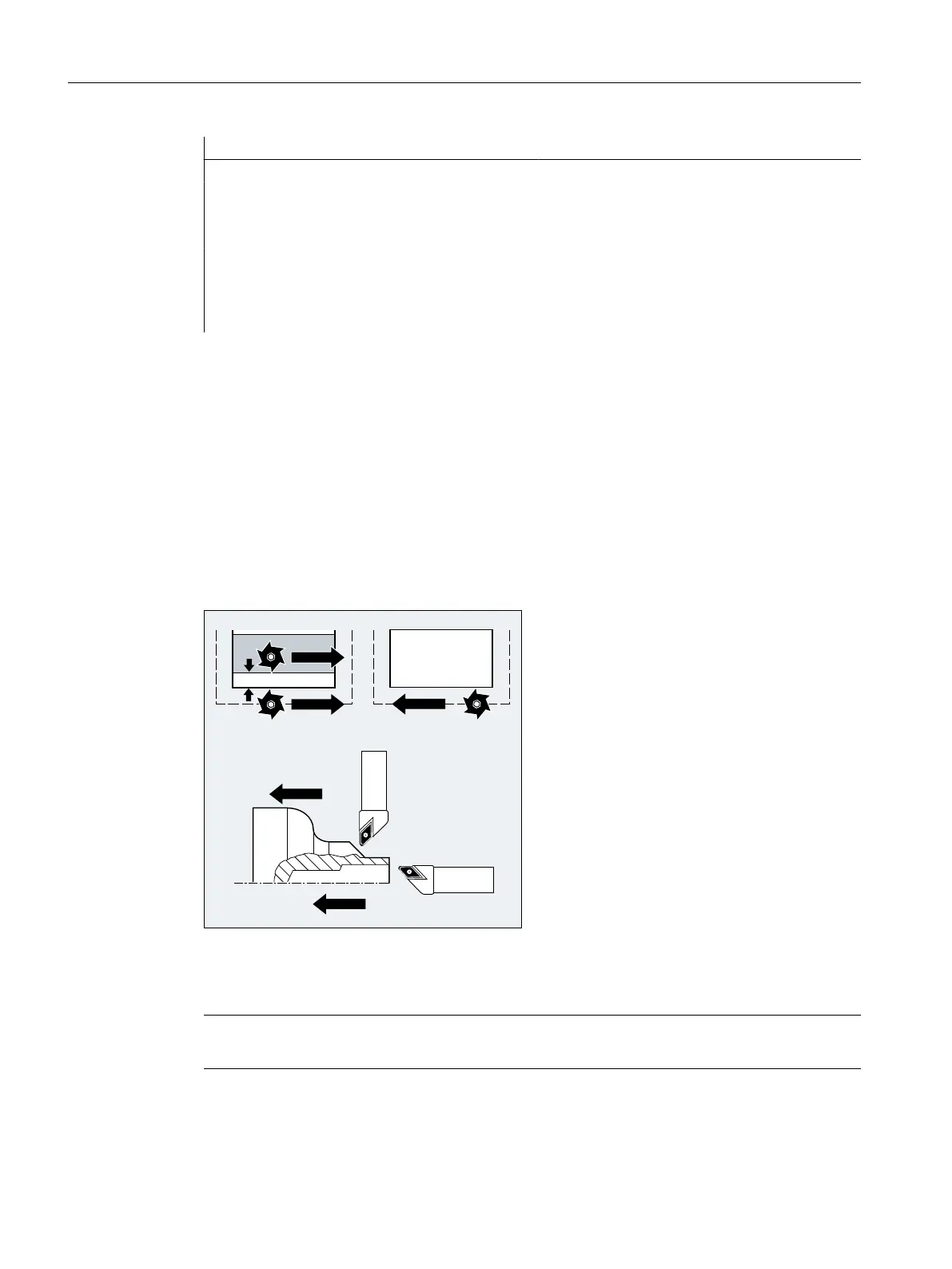

● Machining direction (G41/G42)

● Working plane (G17/G18/G19)

Tool no. (T...), cutting edge no. (D...)

The distance between tool path and workpiece contour is calculated from the milling cutter radii

or cutting edge radii and the specifications of the cutting edge position.

Machining direction (G41/G42)

From this information, the control detects the direction in which the tool path is to be displaced.

Note

A negative correction value has the same significance as a change of offset side (G41 ↔ G42).

Working plane (G17/G18/G19)

Fundamentals

2.10 Tool radius compensation

NC programming

256 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...