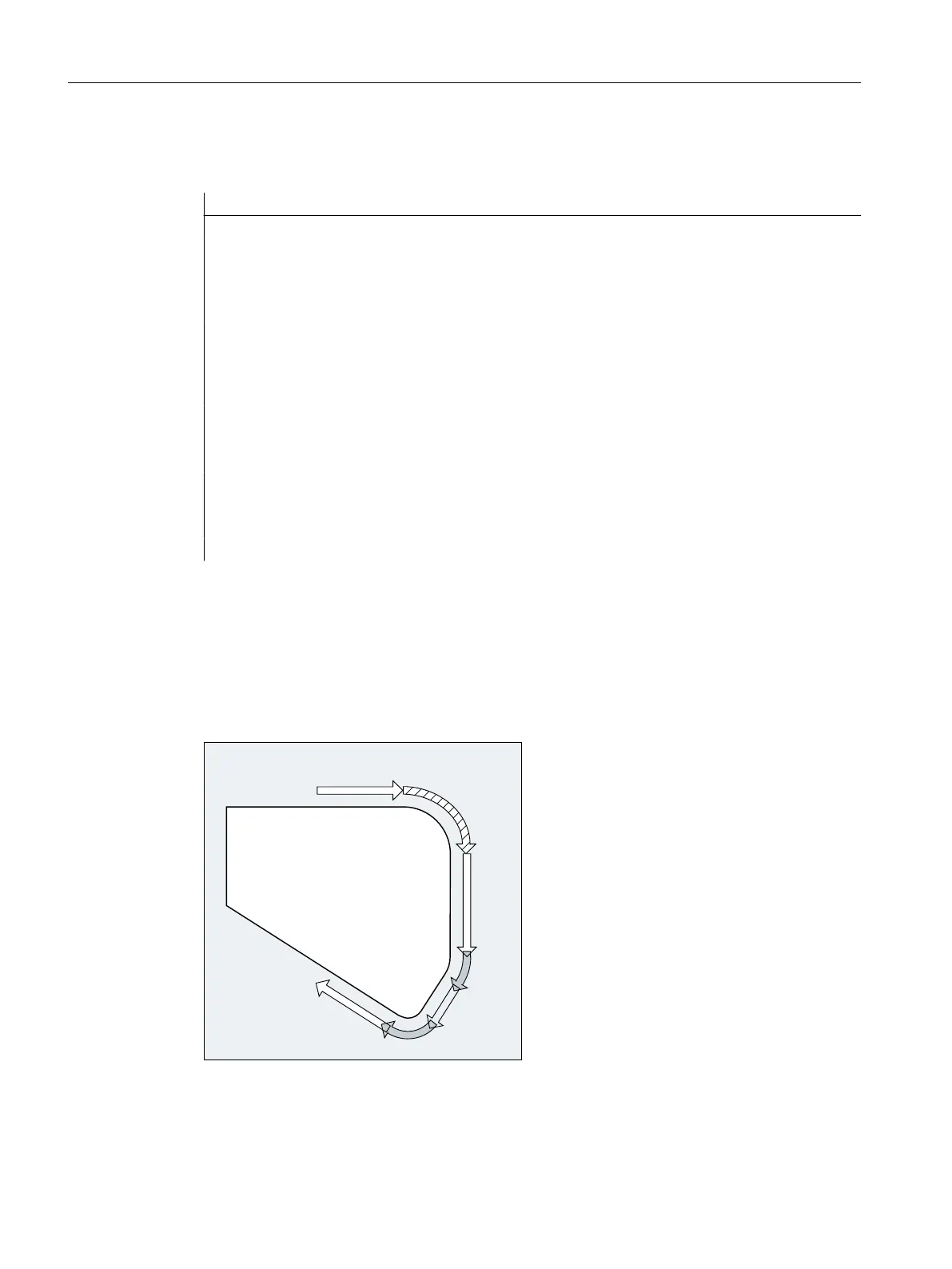

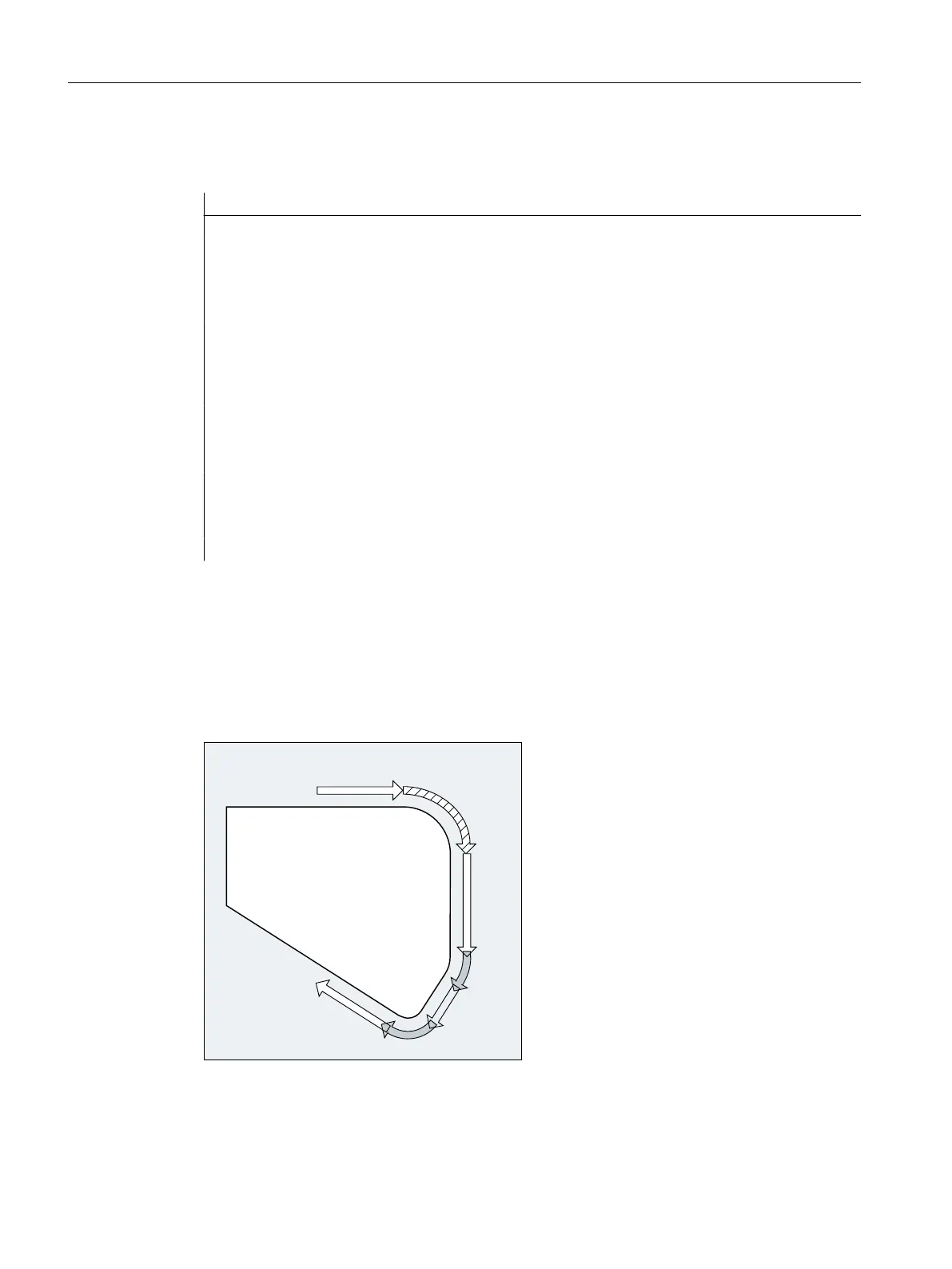

The two outside corners on the groove are to be approached exactly. Otherwise machining

should be performed in continuous-path mode.

Program code Comment

N05DIAMOF ; Radius as dimension

N10 G17 T1 G41 G0 X10 Y10 Z2 S300 M3 ; Approach starting position, acti-

vate spindle, path compensation.

N20 G1 Z-7 F8000 ; Feed in tool.

N30 G641 ADIS=0.5 ; Contour transitions are smoothed.

N40 Y40

N50 X60 Y70 G60 G601 ; Approach position exactly with ex-

act stop fine.

N60 Y50

N70 X80

N80 Y70

N90 G641 ADIS=0.5 X100 Y40 ; Contour transitions are smoothed.

N100 X80 Y10

N110 X10

N120 G40 G0 X-20 ; Deactivate path compensation

N130 Z10 M30 ; Retract tool, end of program.

Further information

Continuous-path mode G64

In continuous-path mode, the tool travels across tangential contour transitions with as constant

a path velocity as possible (no deceleration at block boundaries). LookAhead deceleration is

applied before corners and blocks with exact stop.

Fundamentals

2.11 Path action

NC programming

298 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...