TRANS/ATRANS: Workpiece coordinate system offset in the direction of the specified ge‐

ometry axis or axes

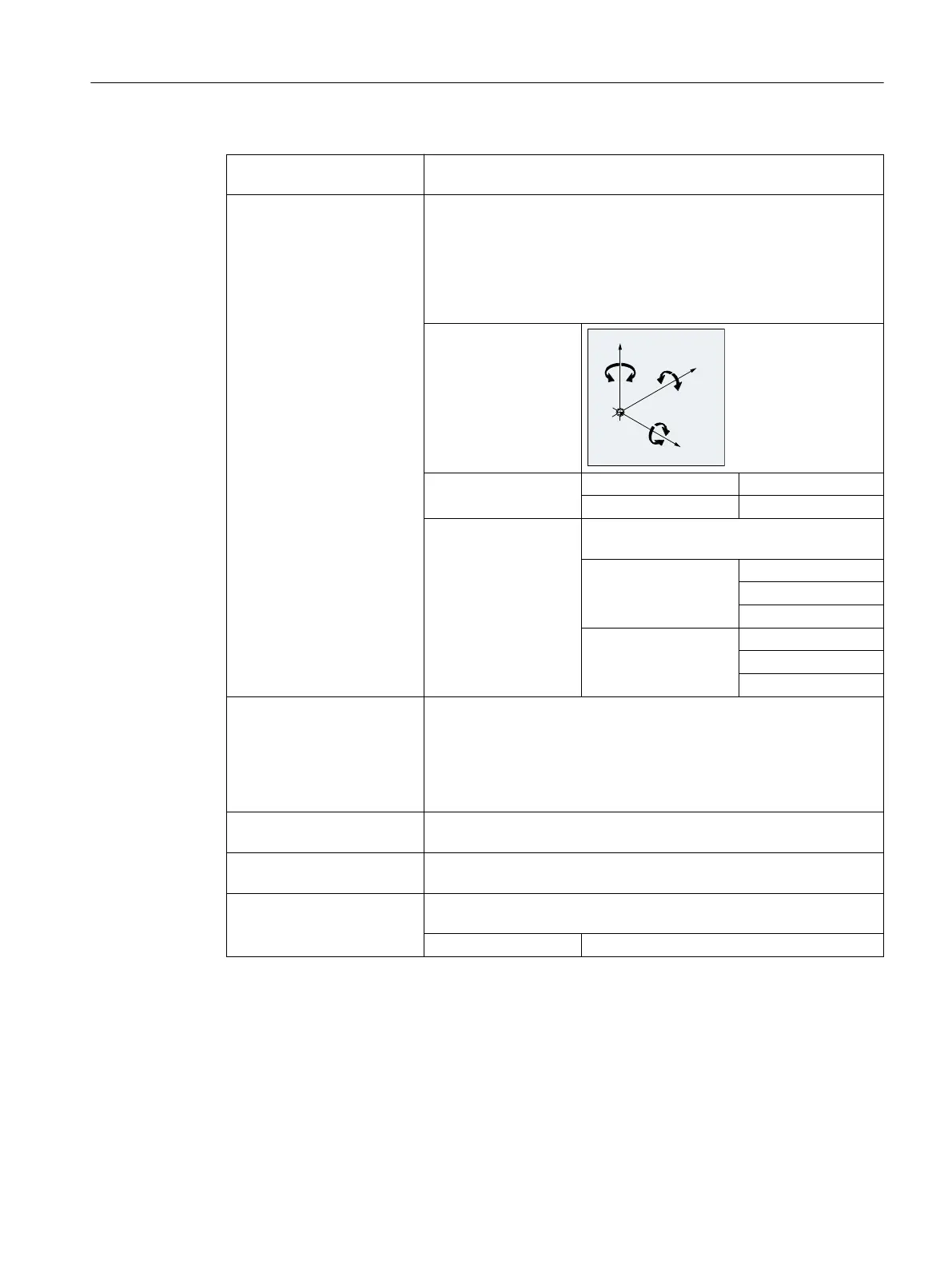

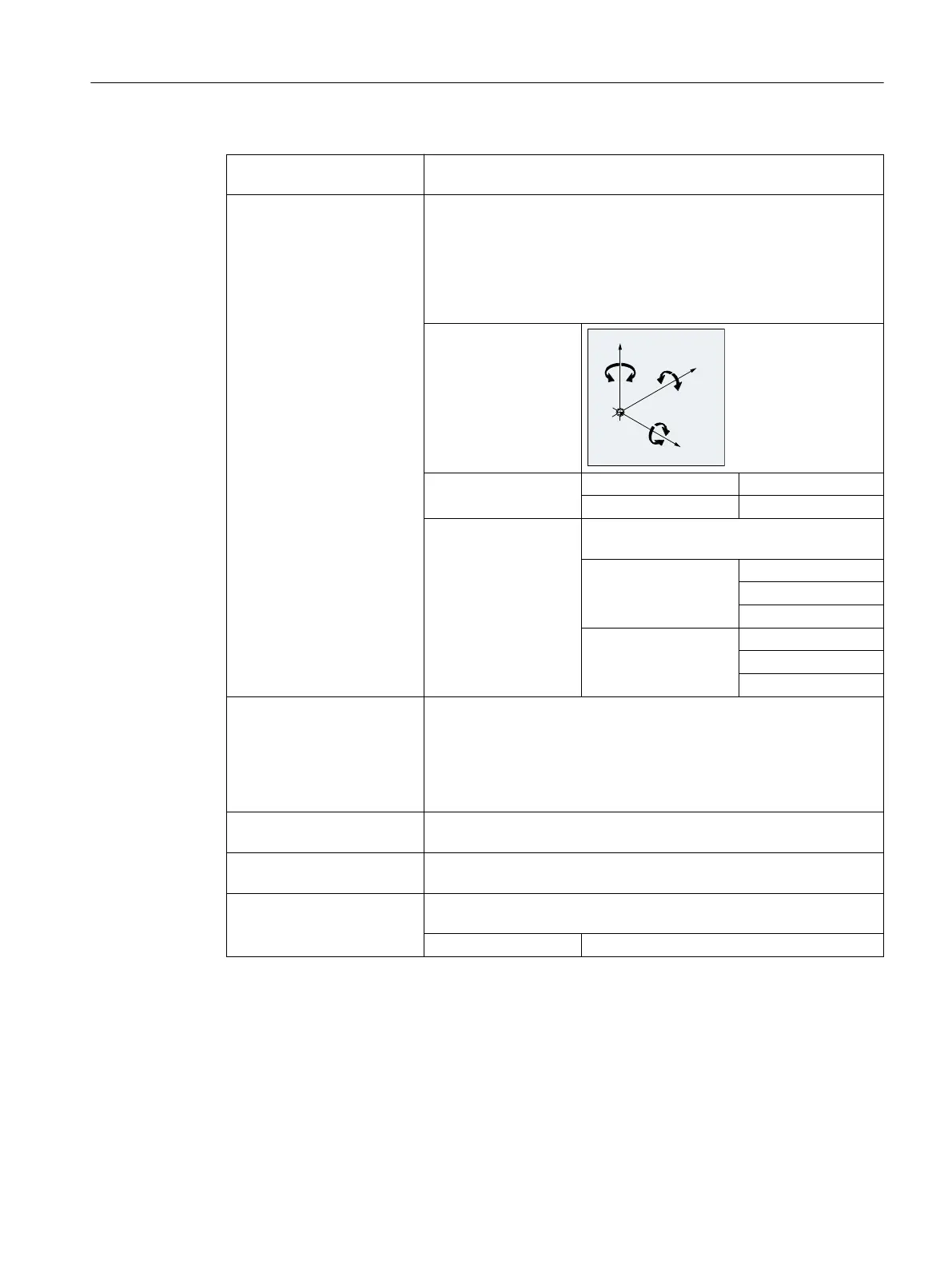

ROT/AROT: Workpiece coordinate system rotation:

● By linking individual rotations around the specified geometry axis or

axes

or

● Around the angle RPL=... in the current working plane

(G17/G18/G19)

Direction of rotation:

Rotation sequence: With RPY notation: Z, Y', X''

With Euler angle: Z, X', Z''

Range of values: The angles of rotation are only defined unam‐

biguously in the following ranges:

With RPY notation: -180 ≤ x ≤ 180

-90 < y < 90

-180 ≤ z ≤ 180

With Euler angle: 0 ≤ x < 180

-180 ≤ y ≤ 180

-180 ≤ z ≤ 180

ROTS/AROTS: Workpiece coordinate system rotation by means of the specification of

solid angles

The orientation of a plane in space is defined unambiguously by speci‐

fying two solid angles. Therefore, up to two solid angles may be pro‐

grammed:

ROTS/AROTS X... Y... / Z... X... / Y... Z...

CROTS: CROTS works in the same way as ROTS but refers to the valid frame in

the database.

SCALE/ASCALE: Scaling in the direction of the specified geometry axis or axes to in‐

crease/reduce the size of a contour

MIRROR/AMIRROR:

Workpiece coordinate system mirroring by means of mirroring (direction

change) the specified geometry axis

Value: Freely selectable (in this case: "0")

Supplementary conditions

● Frame statements must be programmed in a separate NC block.

● Frame statements can be used individually or combined as required.

Fundamentals

2.12 Coordinate transformations (frames)

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 309

Loading...

Loading...