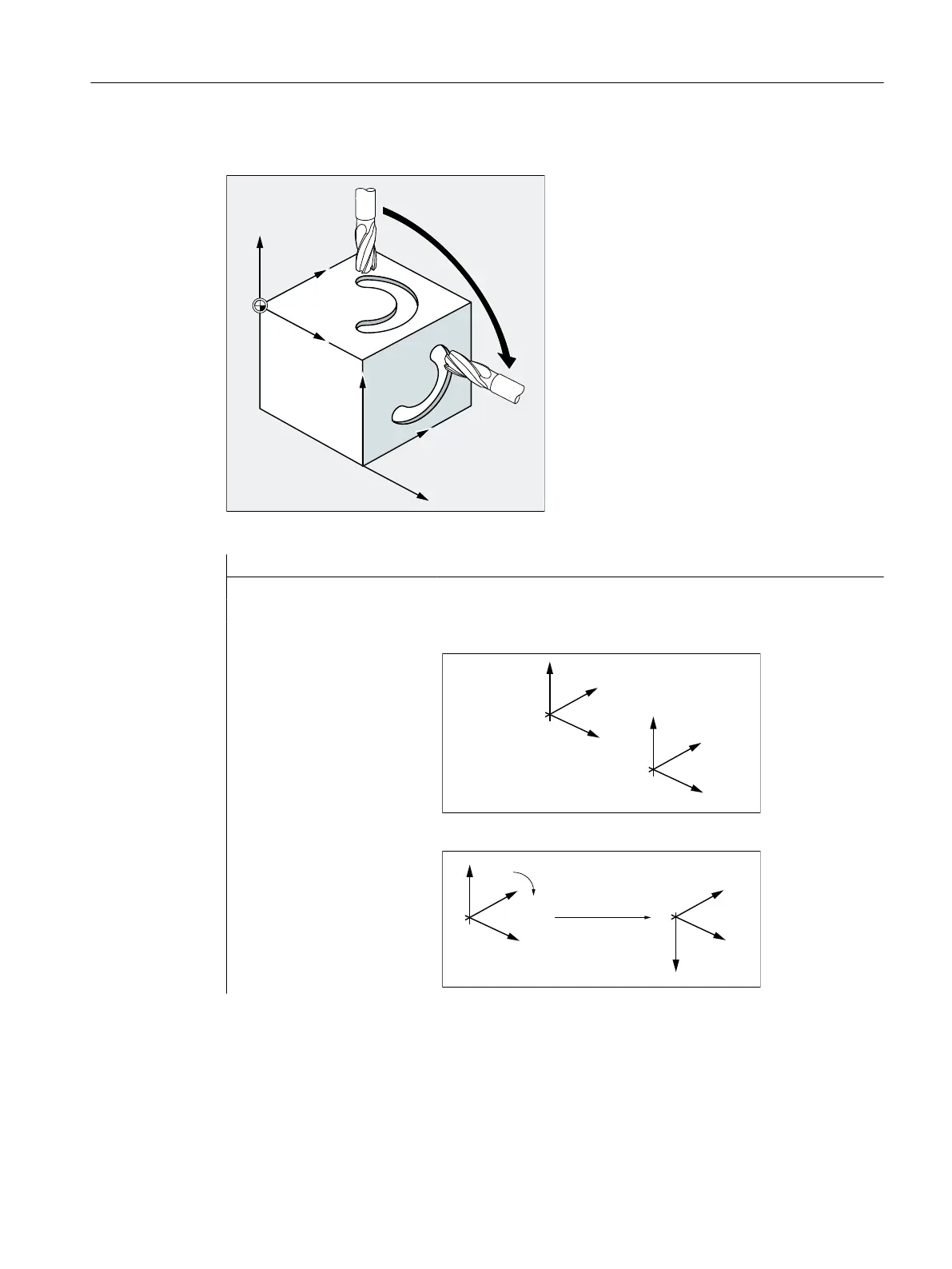

Example 3: Multi-face machining

In this example, identical shapes are ma‐

chined in two workpiece surfaces perpendicu‐

lar to one another via subprograms. In the new

coordinate system on the right-hand work‐

piece surface, infeed direction, working plane

and the zero point have been set up as on the

top surface. Therefore, the conditions required

for the subprogram execution still apply: Work‐

ing plane G17, coordinate plane X/Y, infeed

direction Z.

Program code Comment

N10 G17 G54 ; Working plane X/Y, workpiece zero

N20 L10 ; Subprogram call

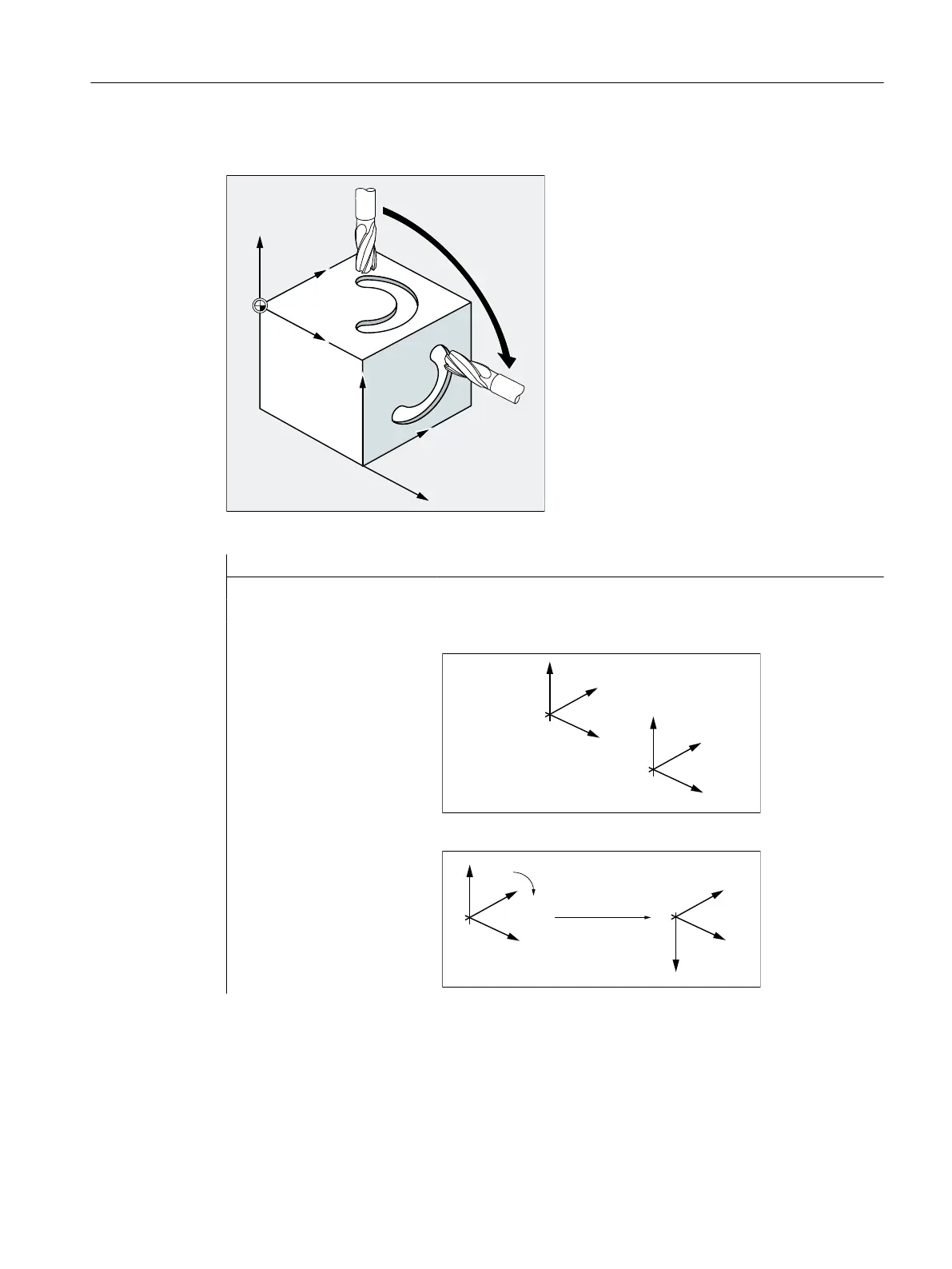

N30 TRANS X100 Z-100 ; Absolute offset of the WCS

75$16;=

<

;

=

<

;

=

N40 AROT Y90 ; Additive rotation of the WCS around Y through 90°

Fundamentals

2.12 Coordinate transformations (frames)

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 319

Loading...

Loading...