Example

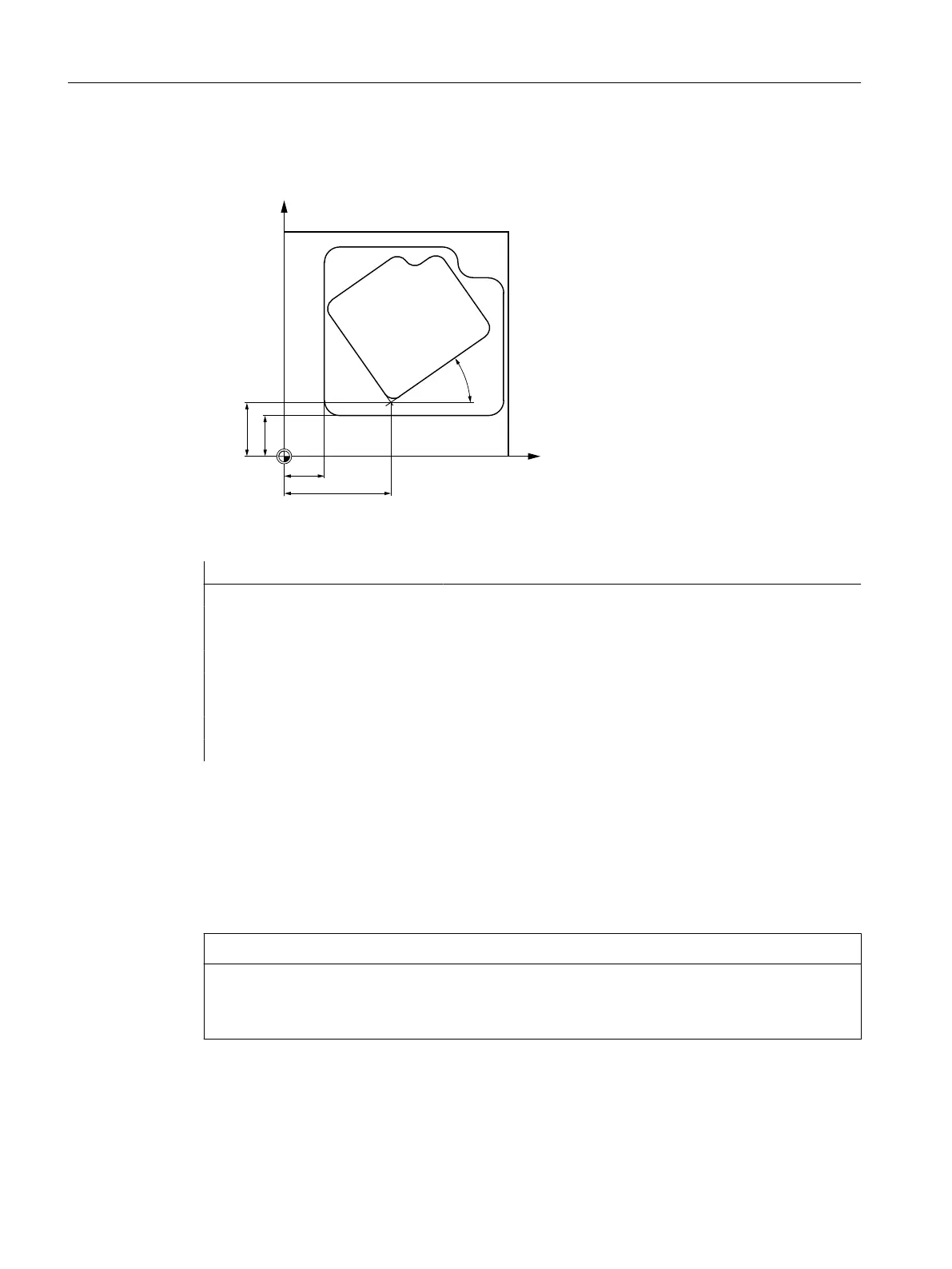

The pocket occurs twice on this workpiece, but

with different sizes and rotated in relation to

one another. The machining sequence is stor‐

ed in the subprogram.

The required workpiece zeroes are set with

zero offset and rotation, the contour is scaled

down with scaling and the subprogram is then

called again.

Program code Comment

N10 G17 G54 ; Working plane X/Y, workpiece zero

N20 TRANS X15 Y15 ; Absolute offset

N30 L10 ; Machine large pocket

N40 TRANS X40 Y20 ; Absolute offset

N50 AROT RPL=35 ; Rotation in the plane through 35°

N60 ASCALE X0.7 Y0.7 ; Scaling factor for the small pocket

N70 L10 ; Machine small pocket

N80G0 X300 Y100 M30 ; Retraction, end of program

Further information

SCALE X... Y... Z...

You can specify an individual scale factor for each axis, by which the shape is to be reduced or

enlarged. The scale refers to the workpiece coordinate system set with G54 to G57, G505 to

G599.

NOTICE

No original frame

The SCALE command resets all frame components of the previously activated programmable

frame.

Fundamentals

2.12 Coordinate transformations (frames)

NC programming

326 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...