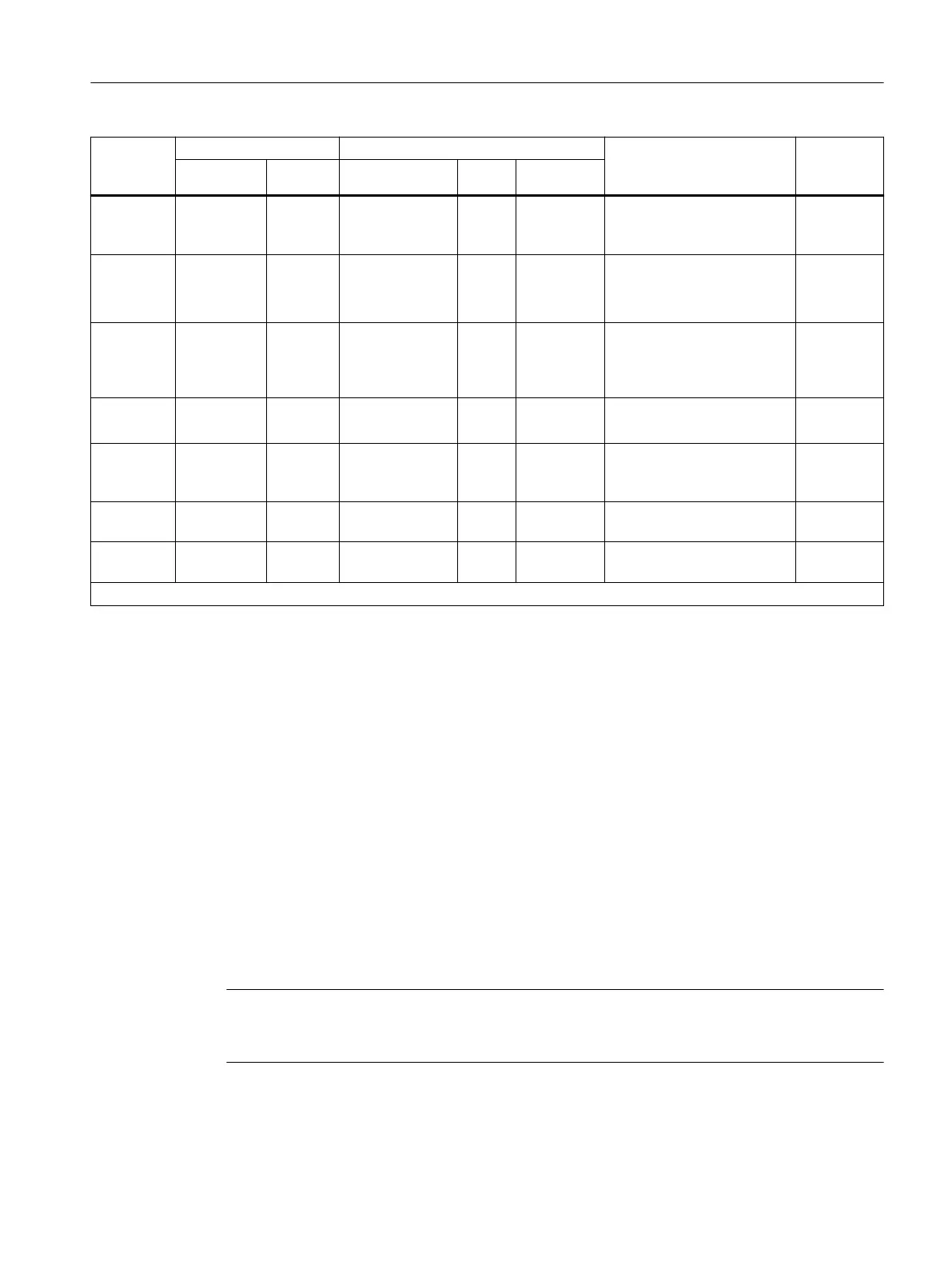

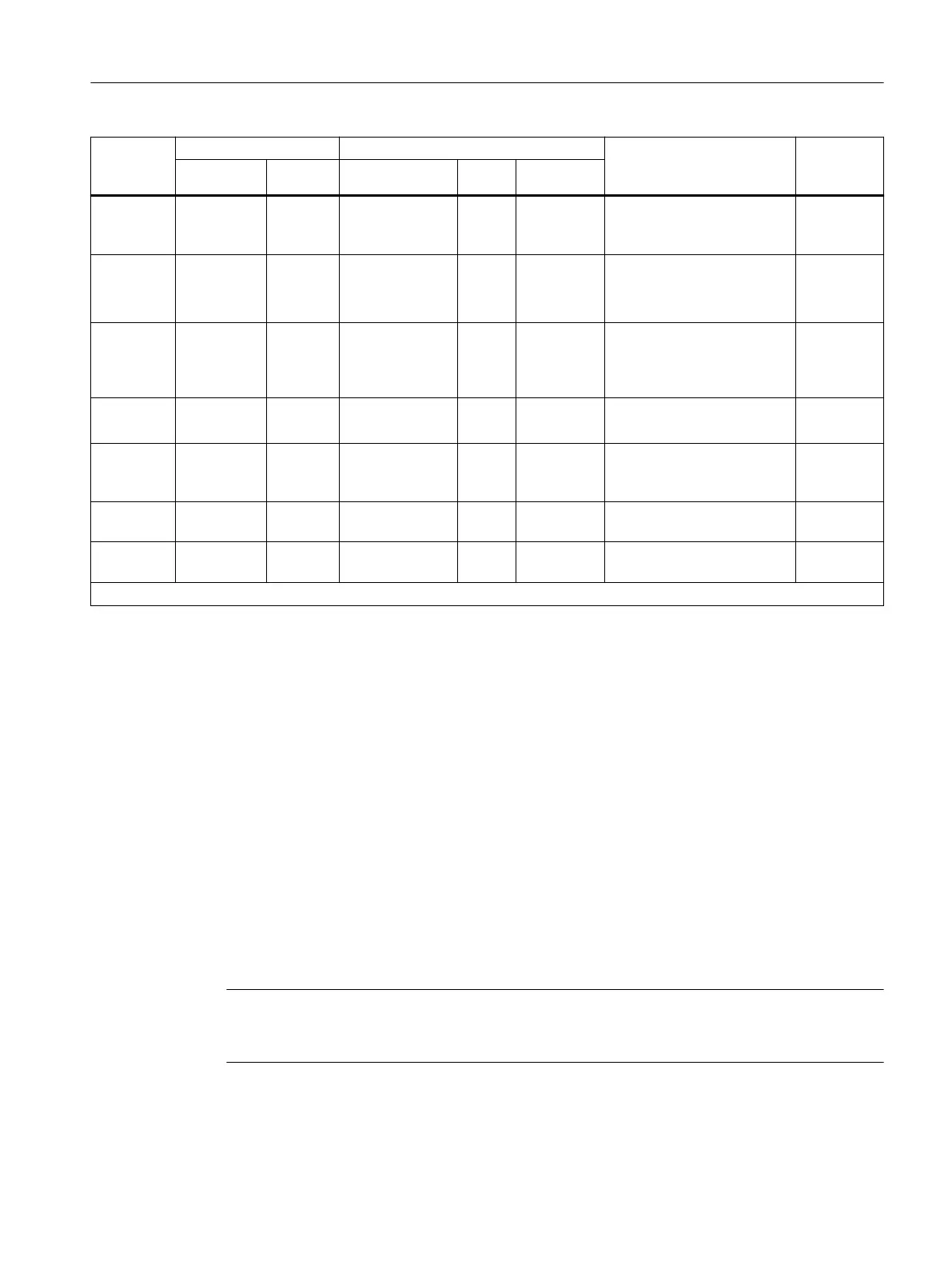

Function Address extension Value Explanations Maximum

number per

block

Meaning Range Range Type Meaning

S Spindle no. 1 - 12 0 ... ± 1.8*10

308

REAL Speed Without spindle number, the

function applies for the mas‐

ter spindle.

3

H Any 0 - 99 0 ...

± 2147483647

± 1.8*10

308

INT

REAL

Any Functions have no effect in

the NC; only to be implemen‐

ted on the PLC.*

3

T Spindle no.

(for active

tool man‐

agement)

1 - 12 0 - 32000

(or tool names

with active tool

management)

INT Tool selec‐

tion

Tool names are not passed

to the PLC interface.

1

D - - 0 - 12 INT Tool offset

selection

D0: Deselection

Default setting: D1

1

DL Location-

dependent

offset

1 - 6 0 ... ± 1.8*10

308

REAL Tool fine

offset selec‐

tion

Refers to previously selec‐

ted D number.

1

F - - 0.001 -

999 999.999

REAL Path fee‐

drate

6

FA Axis No. 1 - 31 0.001 -

999 999.999

REAL Axial fee‐

drate

* The meaning of the functions is defined by the machine manufacturer (see machine manufacturer's specifications).

Further information

Number of function outputs per NC block

Up to 10 function outputs can be programmed in one NC block. Auxiliary functions can also be

output from the action component of synchronized actions.

Grouping

The functions described can be grouped together. Group assignment is predefined for some

M commands. The acknowledgment behavior can be defined by the grouping.

High-speed function outputs (QU)

Functions, which have not been programmed as high-speed outputs, can be defined as high-

speed outputs for individual outputs with the keyword QU. Program execution continues without

waiting for the acknowledgment of the miscellaneous function (the program waits for the

transport acknowledgment). This helps avoid unnecessary hold points and interruptions to

traversing movements.

Note

The appropriate machine data must be set for the "High-speed function outputs" function

(→ machine manufacturer).

Fundamentals

2.13 Auxiliary function outputs

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 343

Loading...

Loading...