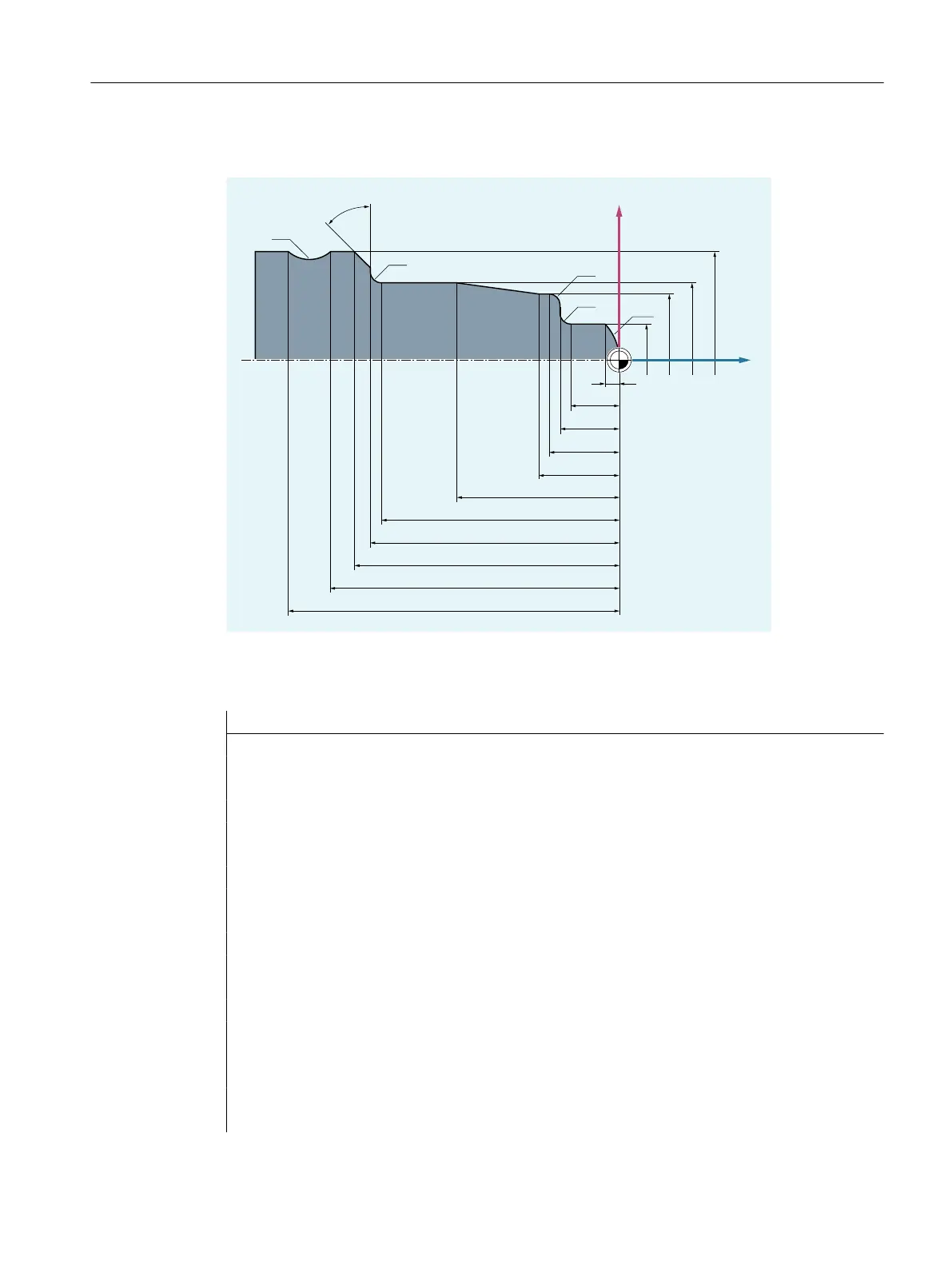

Dimension drawing of the workpiece

5

5

5

5

5

r

;

=

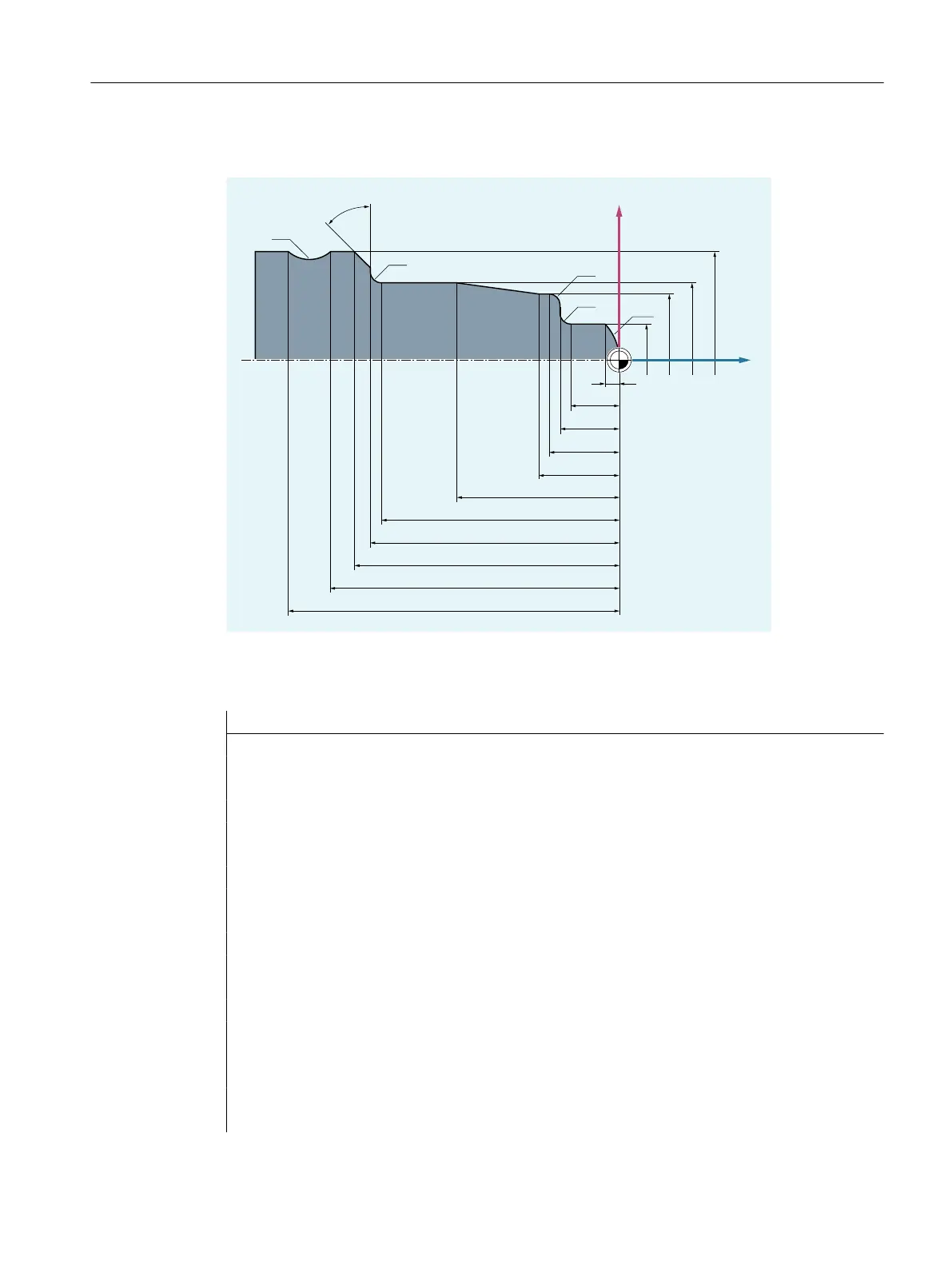

NC program

Program code Comment

N5 G0 G53 X280 Z380 D0 ; Starting point.

N10 TRANS X0 Z250 ; Work offset.

N15 LIMS=4000 ; Speed limitation (G96).

N20 G96 S250 M3 ; Select constant cutting rate.

N25 G90 T1 D1 M8 ; Select tool selection and offset.

N30 G0 G42 X-1.5 Z1 ; Set tool with tool radius compensation.

N35 G1 X0 Z0 F0.25

N40 G3 X16 Z-4 I0 K-10 ; Turn radius 10.

N45 G1 Z-12

N50 G2 X22 Z-15 CR=3 ; Turn radius 3.

N55 G1 X24

N60 G3 X30 Z-18 I0 K-3 ; Turn radius 3.

N65 G1 Z-20

N70 X35 Z-40

N75 Z-57

N80 G2 X41 Z-60 CR=3 ; Turn radius 3.

N85 G1 X46

N90 X52 Z-63

Fundamentals

2.3 Creating an NC program

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 55

Loading...

Loading...