Referencing status

By setting a new actual value in the machine coordinate system, the referencing status of the

machine axis is reset:

DB31, ... DBX60.4/.5 = 0 (referenced / synchronized measuring system 1/2)

It is recommended that PRESETON only be used for axes that do not require a reference point.

To restore the original machine coordinate system, the measuring system of the machine axis

must be referenced again, e.g. through active referencing from the part program (G74).

CAUTION

Loss of the referencing status

By setting a new actual value in the machine coordinate system with PRESETON, the

referencing status of the machine axis is reset to "not referenced/synchronized".

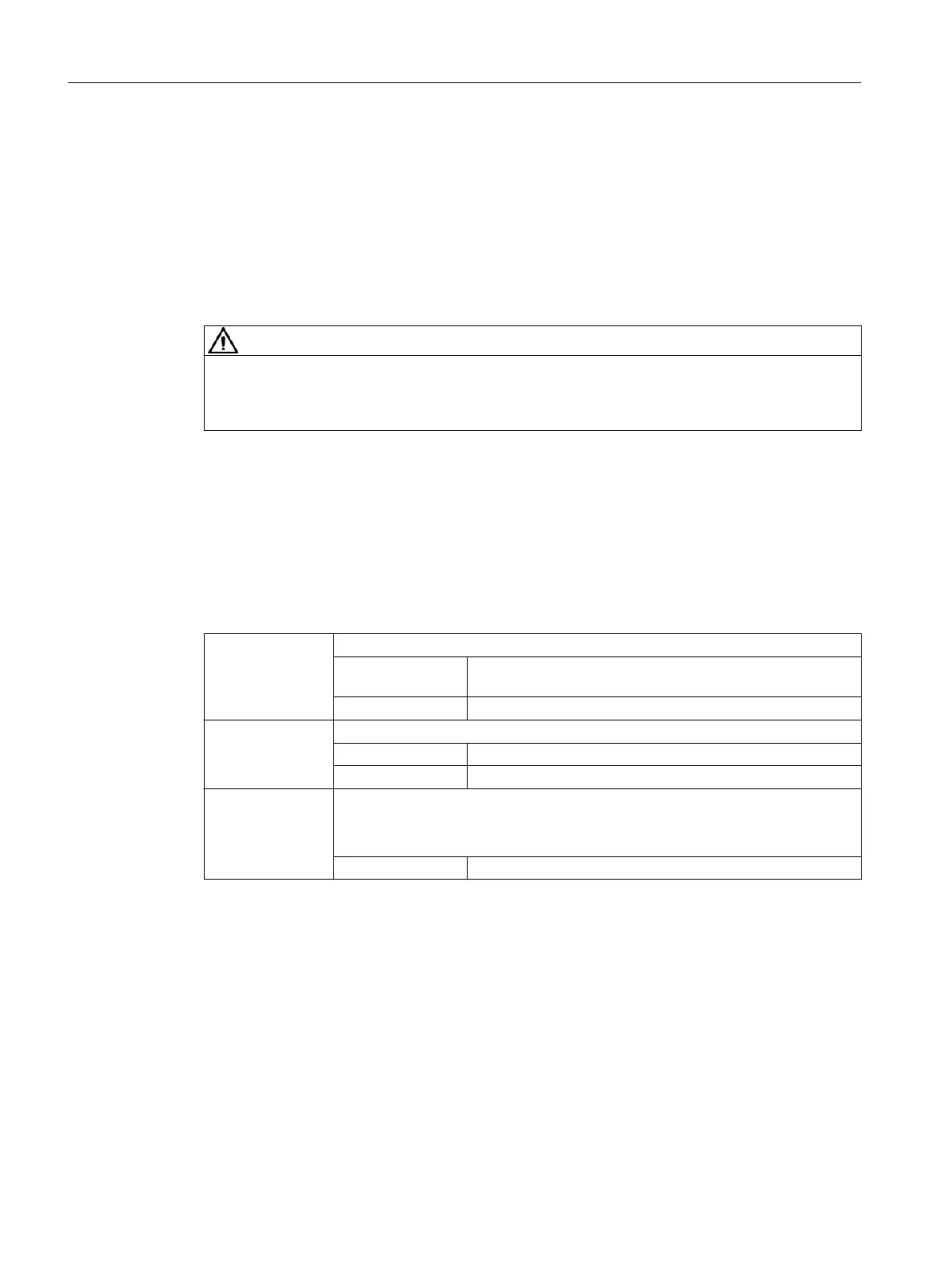

Programming

Syntax

PRESETON(<axis_1>, <value_1> [, <axis_2>, <value_2>, ... <axis_8>,

<value_8>])

Meaning

PRESETON: Set actual value with loss of the referencing status

Preprocessing

stop:

yes

Alone in the block: yes

<axis_x>: Machine axis name

Type: AXIS

Value range: Machine axis names defined in the channel

<value_x>: New actual value of the machine axis in the machine coordinate system (MCS)

The input is made in the currently valid measuring system (inch/metric)

An active diameter programming (DIAMON) is taken into account

Type: REAL

Further information

PRESETON in NC programs

A detailed description of PRESETON in NC programs is provided in the Function Manual Basic

Functions.

PRESETONS in synchronized actions

A detailed description of PRESETON in synchronized actions is provided in Function Manual

Synchronized Actions.

Work preparation

3.8 Coordinate transformations (frames)

NC programming

642 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...