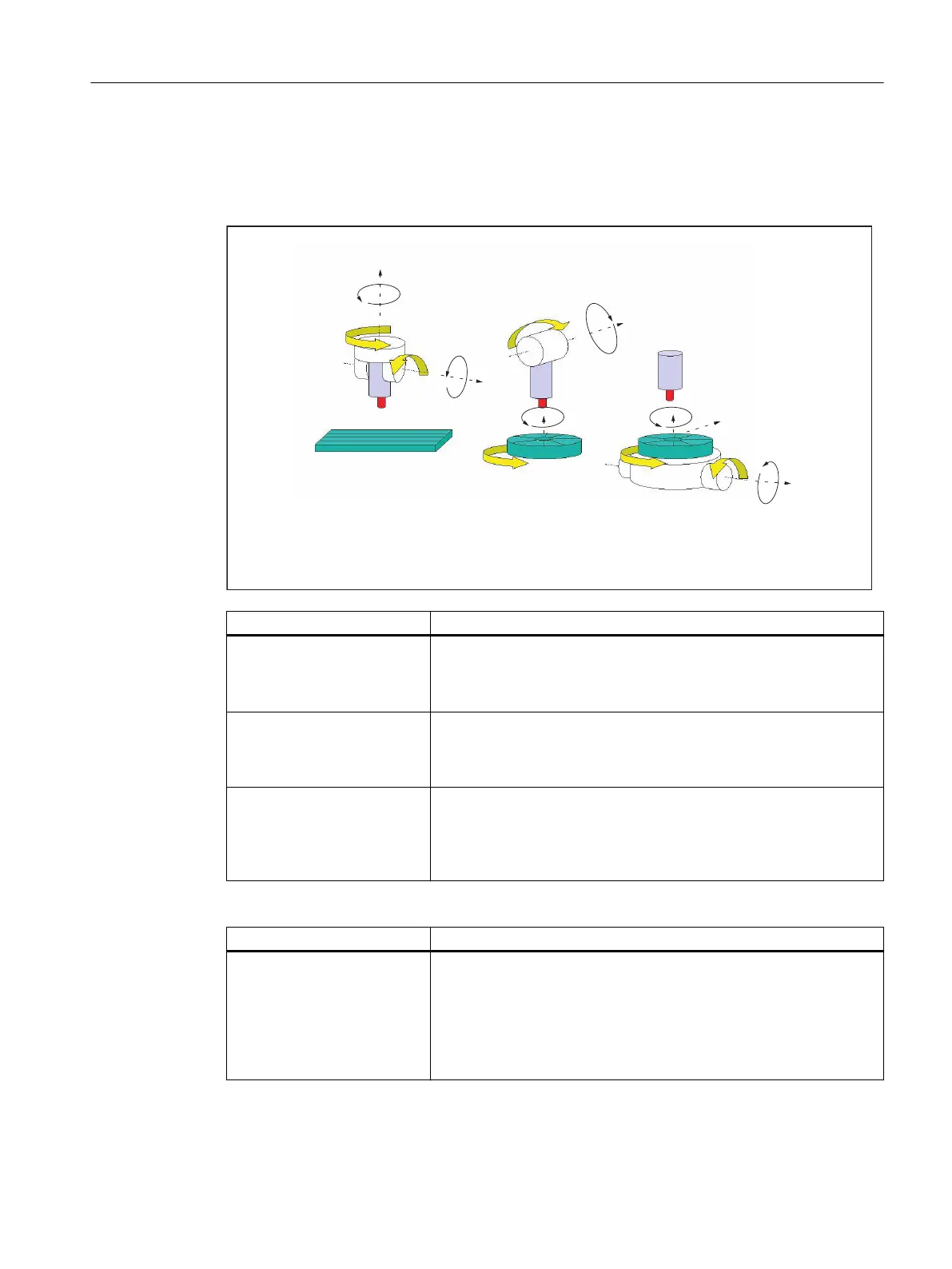

Machine kinematics for three, four and five axis transformation (TRAORI)

Either the tool or the tool table can be rotatable with up to two rotary axes. A combination of

swivel head and rotary table (single-axis in each case) is also possible.

Rotated workpiece

Machine type 2 with

axis sequence AC

Rotated tool Rotated

workpiece

Machine type 3 with

axis sequence BC

Rotated tool

Machine type 1 with

axis sequence CA

A

CC

B

A

C

Y

X

Tool table, fixed

Tool table, can

be rotated

about Z axis

Tool table, can

be rotated

about X axis

and Z axis

Swivel head,

fixed

Swivel head,

can be rotated

about Y axis

Swivel head,

can be rotated

about X axis

and Z axis

Z Z

Y

X

Z

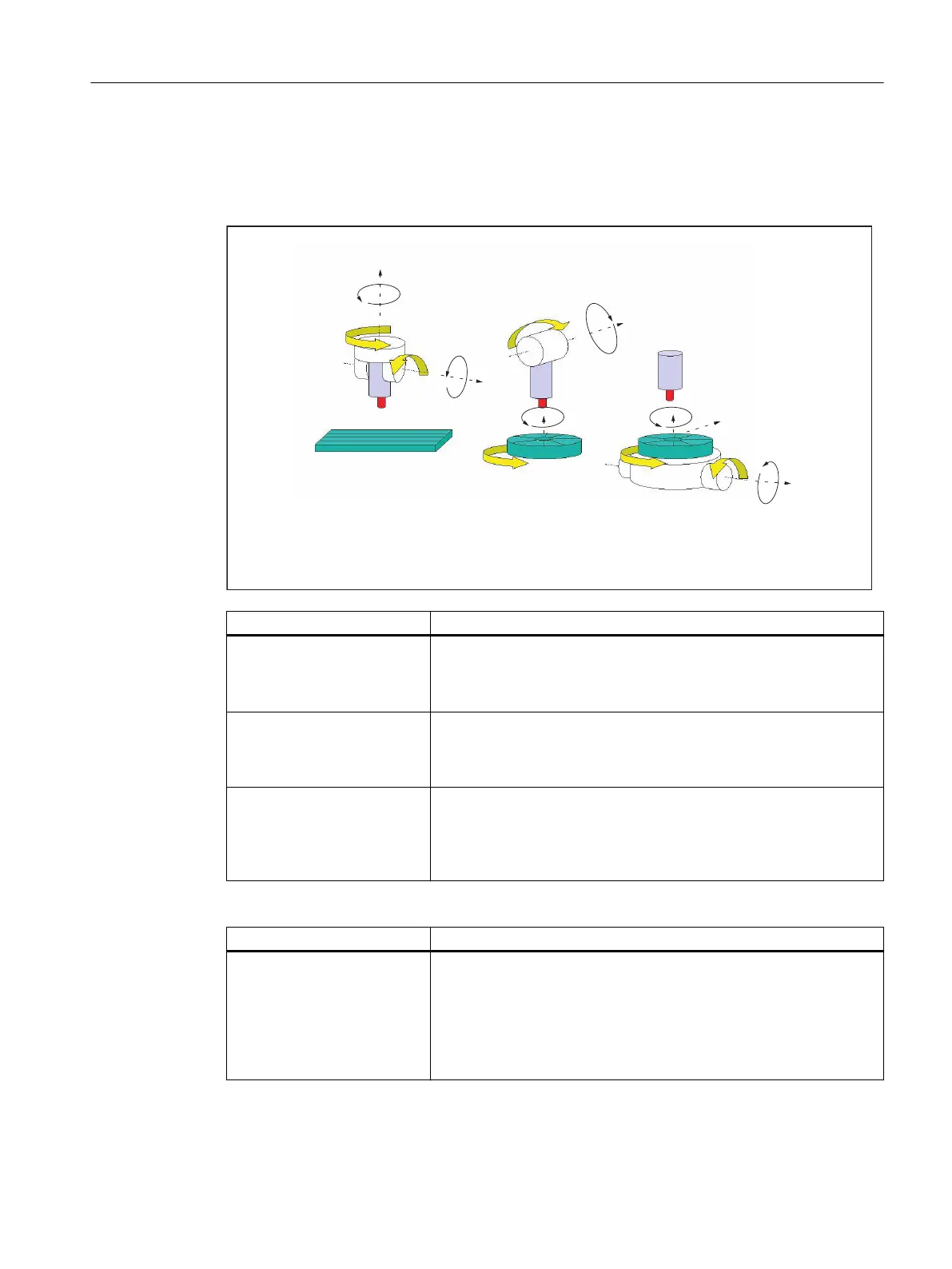

Machine type Programming of orientation

Three-axis transformation ma‐

chine types 1 and 2

Programming of tool orientation only in the plane, which is perpendic‐

ular to the rotary axis. There are

two translatory axes (linear axes) and

one axis of rotation (rotary axis).

Four-axis transformation ma‐

chine types 1 and 2

Programming of tool orientation only in the plane, which is perpendic‐

ular to the rotary axis. There are

three translatory axes (linear axes) and

one axis of rotation (rotary axis).

Five-axis transformation ma‐

chine types 3

Single-axis swivel head and

single-axis rotary table

Programming of orientation transformation. Kinematics with

three linear axes and two orthogonal rotary axes.

The rotary axes are parallel to two of the three linear axes. The first

rotary axis is moved by two Cartesian linear axes. It rotates the third

linear axis with the tool. The second rotary axis rotates the workpiece.

Generic 5/6-axis transformations

Machine type Programming of orientation transformation

Generic five/six-axis transfor‐

mation machine types 4

Two-axis swivel head with tool

which rotates around itself and

single-axis rotary table

Programming of orientation transformation. Kinematics with

three linear axes and three orthogonal rotary axes.

The rotary axes are parallel to two of the three linear axes. The first

rotary axis is moved by two Cartesian linear axes. It rotates the third

linear axis with the tool. The second rotary axis rotates the workpiece.

The basic tool orientation can also be programmed with additional ro‐

tation of the tool around itself with the THETA rotary angle.

When calling "generic three-, four-, and five/six-axis transformation", the basic orientation of the

tool can also be transferred. The restrictions in respect of the directions of the rotary axes no

longer apply. If the rotary axes are not exactly vertical to one another or existing rotary axes are

Work preparation

3.9 Transformations

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 657

Loading...

Loading...