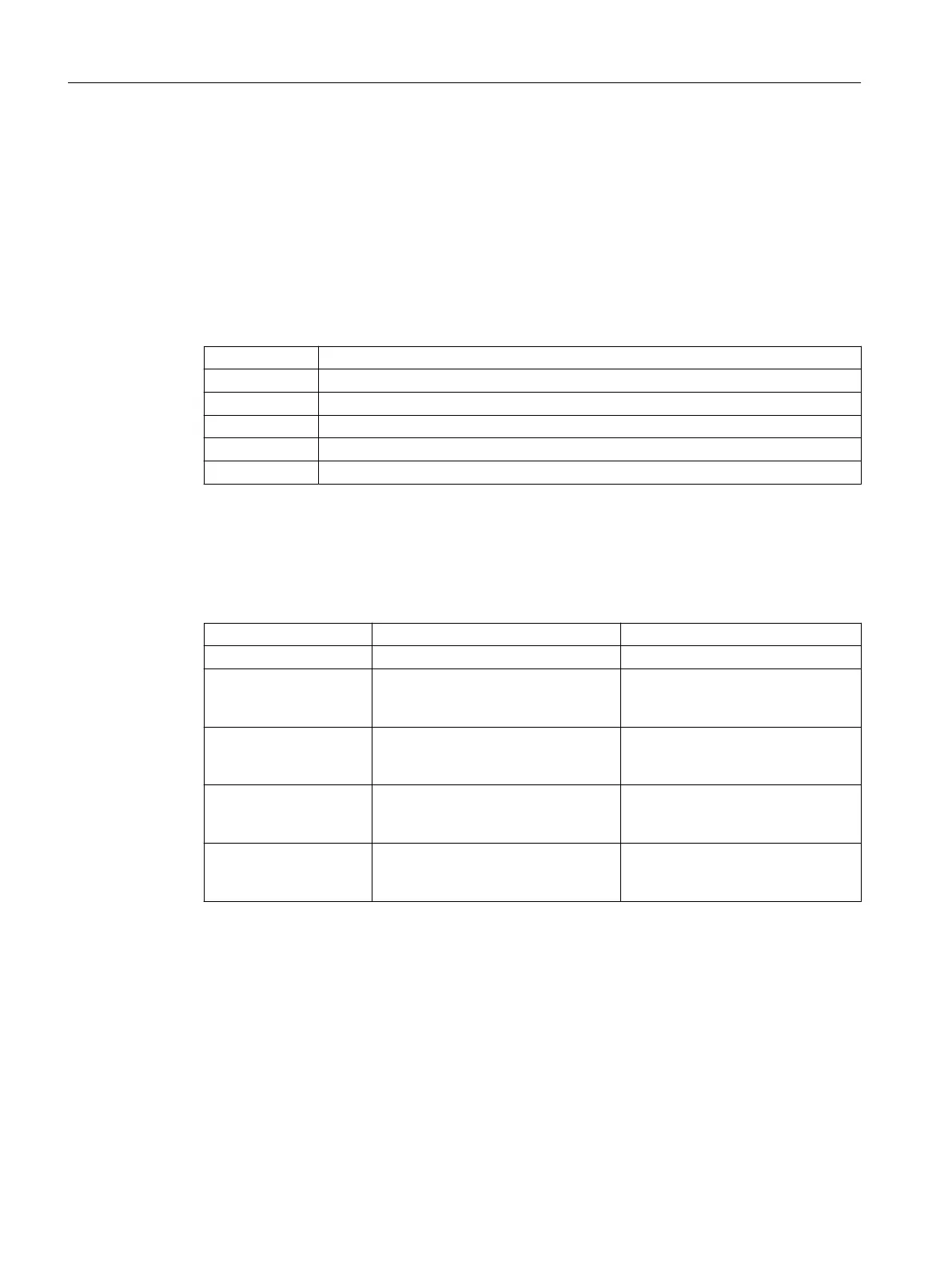

Syntax

TOWSTD

TOWMCS

TOWWCS

TOWBCS

TOWTCS

TOWKCS

Meaning

TOWSTD: Initial setting value for offsets in tool length wear value

TOWMCS: Offsets in tool length in MCS

TOWWCS: Offsets in tool length in WCS

TOWBCS: Offsets in tool length in BCS

TOWTCS: Offsets in tool length at tool carrier reference point (orientable tool carrier)

TOWKCS: Compensations of tool length for tool head (kinematic transformation)

Further information

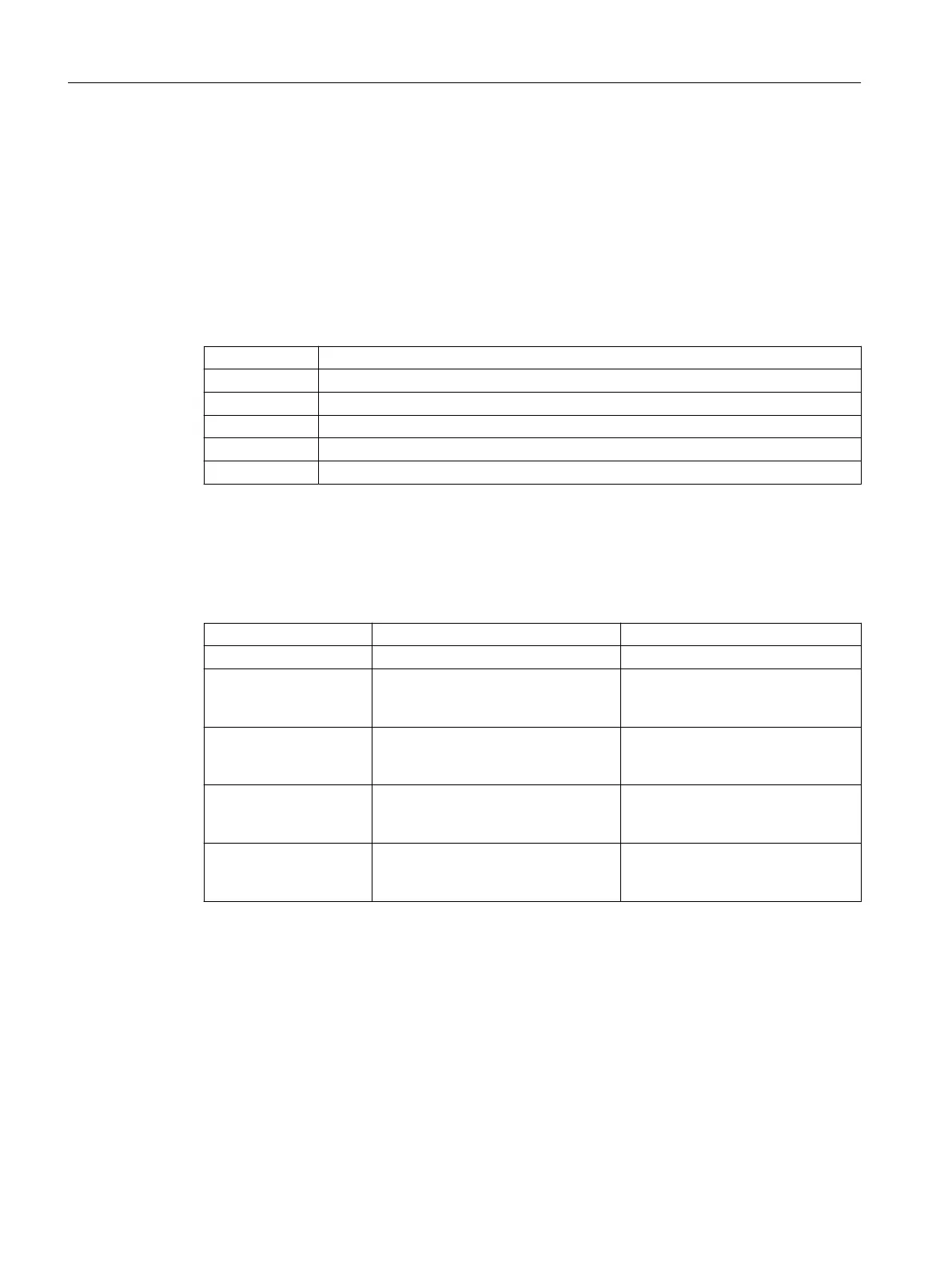

Distinguishing features

The most important distinguishing features are shown in the following table:

G command Wear value Active orientable tool carrier

TOWSTD Initial value, tool length Wear values are subject to rotation.

TOWMCS Wear value in MCS. TOWMCS is

identical to TOWSTD if a tool carrier

that can be orientated is not active.

It only rotates the vector of the resul‐

tant tool length without taking into

account the wear.

TOWWCS The wear value is converted to the

MCS in the WCS.

The tool vector is calculated as for

TOWMCS without taking into ac‐

count the wear.

TOWBCS The wear value is converted to the

MCS in the BCS.

The tool vector is calculated as for

TOWMCS without taking into ac‐

count the wear.

TOWTCS The wear value is converted to the

MCS in the workpiece coordinate sys‐

tem.

The tool vector is calculated as for

TOWMCS without taking into ac‐

count the wear.

TOWWCS, TOWBCS, TOWTCS: The wear vector is added to the tool vector.

Linear transformation

The tool length can be defined meaningfully in the MCS only if the MCS is generated by linear

transformation from the BCS.

Non-linear transformation

For example, if with TRANSMIT a non-linear transformation is active, then when specifying the

MCS as requested coordinate system, BCS is automatically used.

Work preparation

3.13 Tool offsets

NC programming

748 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...