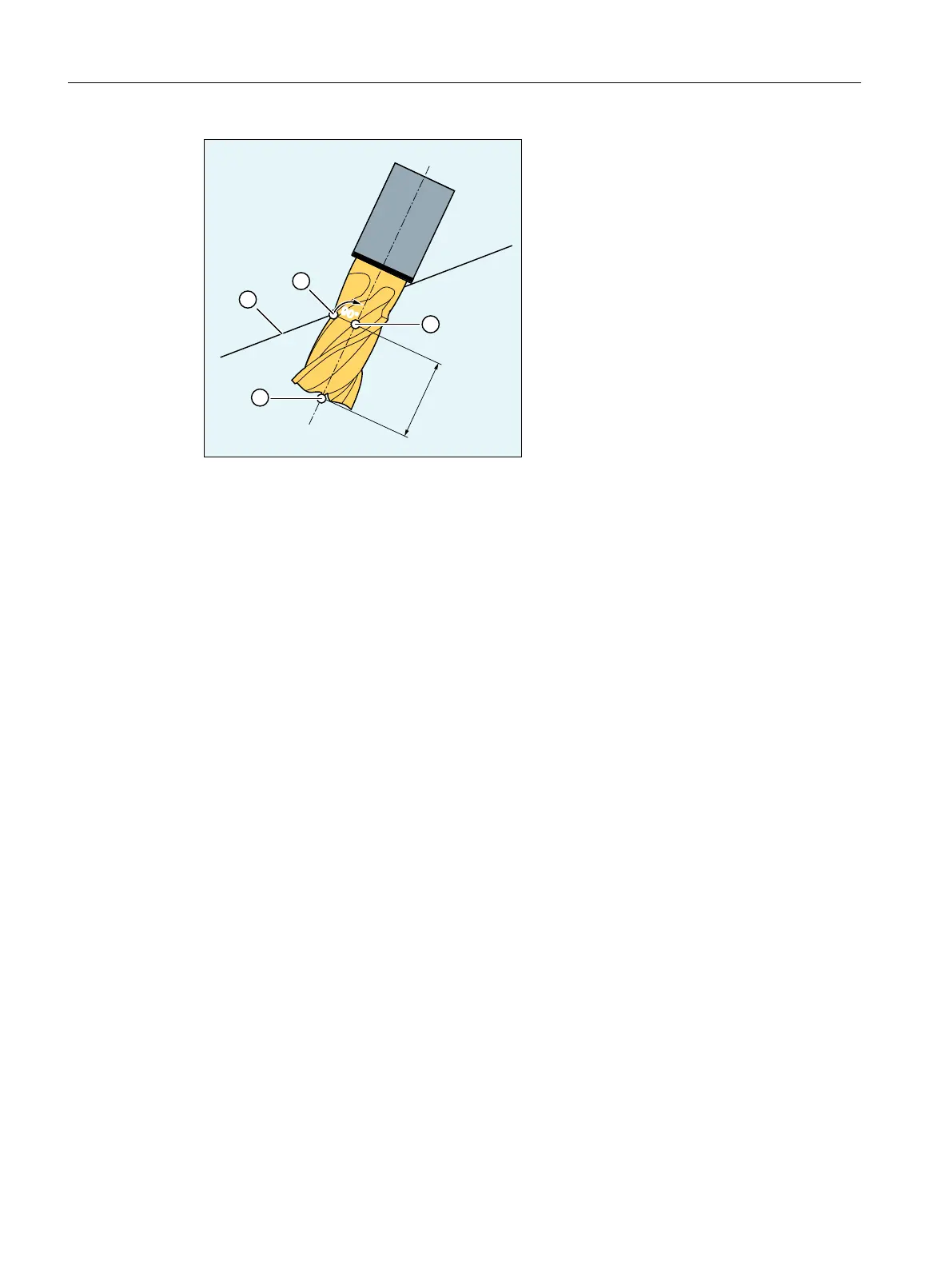

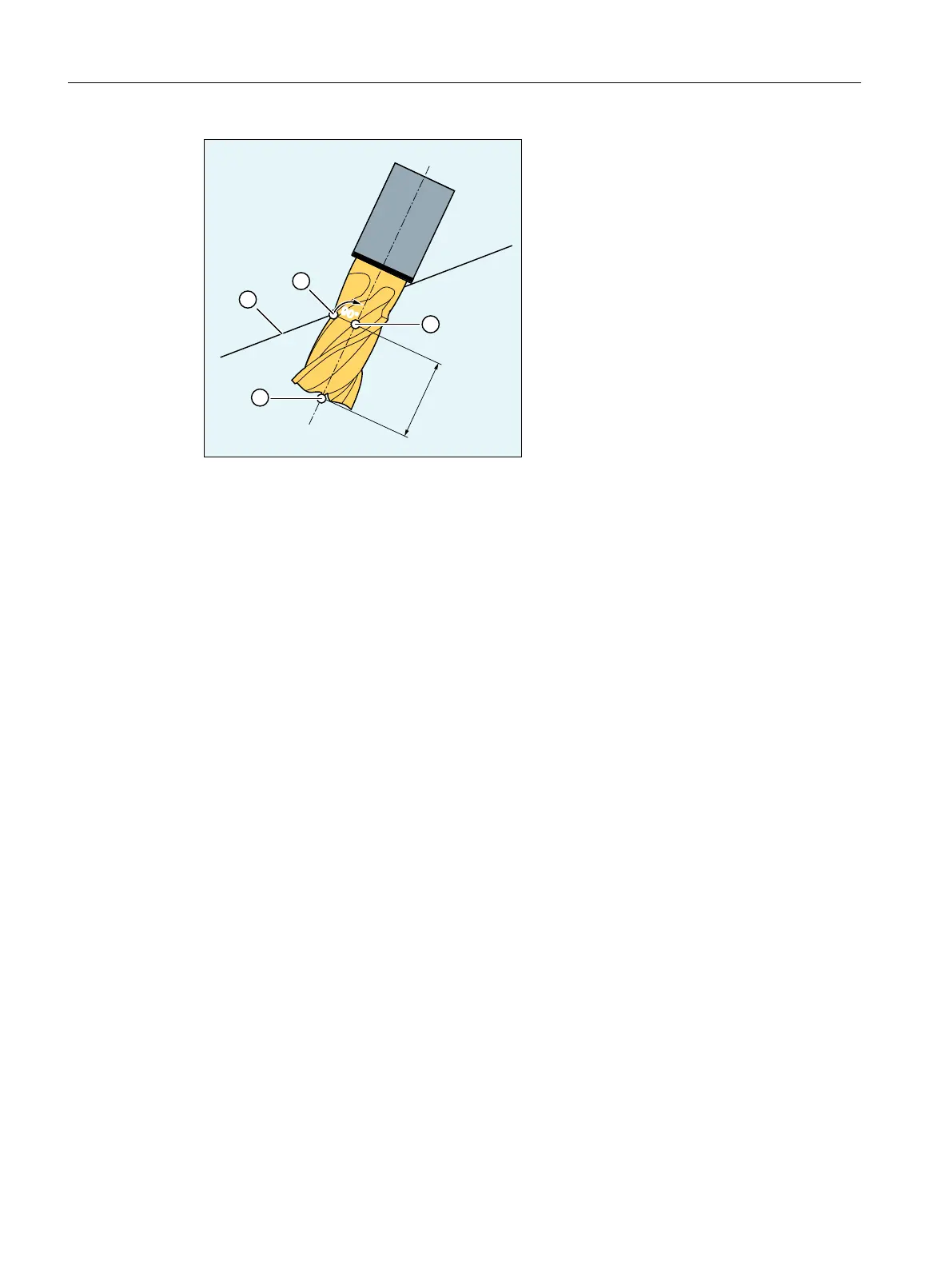

① Programmed path

② Milling tool machining point

③ Milling tool reference point

④ Milling tool tip

ISD Insertion depth (InSertion Depth)

Figure 3-9 Insertion depth

Tool radius compensation referred to a differential tool

3D TRC for circumferential milling referred to a differential tool is activated via the CUT3DCD

command. It should be applied if the programmed contour refers to the center-point path of a

standard tool, and a tool other than a differential tool is used for machining. When calculating

the 3D tool radius compensation, only the wear value of the radius of the active tool

($TC_DP15) and any programmed tool offsets OFFN and TOFFR/TOFFLR are taken into

account. The basic radius ($TC_DP6) of the active tool is not taken into account.

Pocket milling with inclined side walls for circumferential milling with CUT3DC

In this 3D tool radius compensation, a deviation of the mill radius is compensated by infeed

toward the surface normals to be machined. The plane, in which the milling tool face is located,

remains unchanged if the insertion depth ISD has remained the same. For example, a milling

tool with a smaller radius than a standard tool would not reach the pocket base, which is also

the limitation surface. For automatic tool infeed, this limitation surface must be known to the

control, see Section "3D circumferential milling taking into account a limitation surface

(CUT3DCC, CUT3DCCD) (Page 765)".

Work preparation

3.13 Tool offsets

NC programming

758 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...